Get Tech Tips

Subscribe to free tech tips.

Troubleshooting for HVAC/R – Data Analysis

This article is part 4 of a 5-part series on troubleshooting by Senior Refrigeration and HVAC tech Jeremy Smith

Ok, so we've got our data scribbled and scratched out on paper. Maybe a bit of grease, dirt, and oil, too, if you're doing things right—blood if you're doing it wrong.

Now, time to take a short break and congratulate ourselves on doing it right while sitting and thinking. Have a coffee and look over your data. Now, you have some decisions to make.

Much has already been published on analyzing data on a refrigeration system, so I don't think I need to reinvent the wheel here and review various combinations of pressures, superheat and subcooling, and airflows. If you haven't yet internalized this information, don't be afraid to have a nice laminated copy of the printout on your truck until you do.

The thing to remember here is that the more data you have and the more accurate that data is, the easier troubleshooting will be for you.

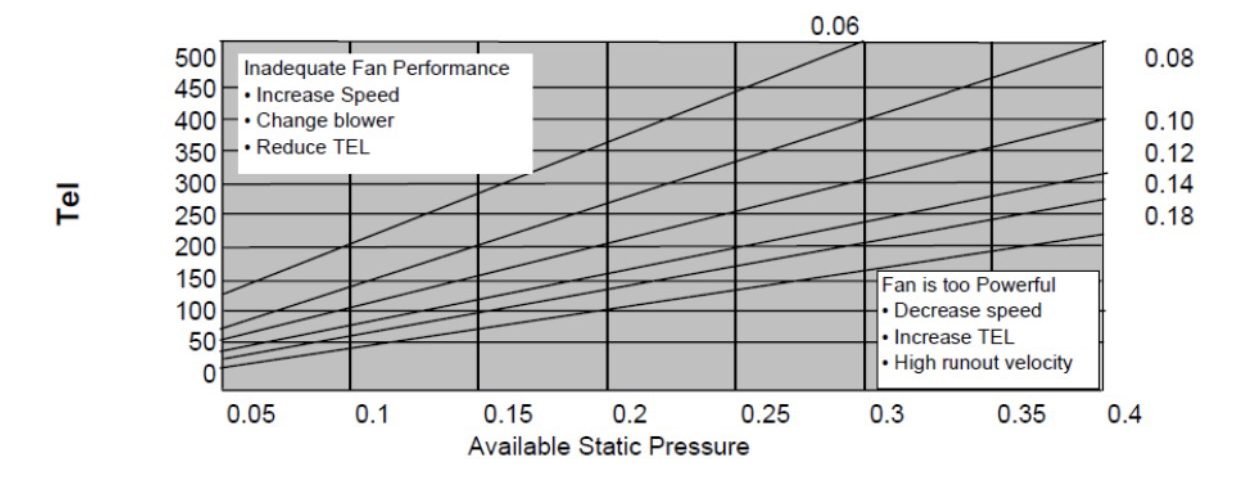

As an example, suppose you've got a unit with a TEV running a 10° subcooling, and your low side shows a lower than expected suction pressure and superheat. Do you have an airflow problem, a low load problem, or a sizing issue? Without collecting good data, it can be difficult to distinguish the problems, but if you've taken TESP readings, return and supply, dry and wet bulb temps, and have the unit model/serial info on hand when you sit down to analyze the data, the problem should be more apparent.

Evaluate the patterns in the data. Look broadly at all the data and see the patterns. If you have a good data set and a good understanding of the operation of this equipment, a “Most Likely” candidate for the problem is going to emerge.

The final step is coming tomorrow.

—Jeremy

Here are the previous installments of the series:

Comments

That was well said . One thing I find so easy these days regarding collecting data to determine the source of problem causing issues is that it can be done in relatively a short amount of time.. I have 3 apps on my phone for collecting and calculating Wet bulb/Dry bulb temps, SUBCOOLING/SUPERHEAT values ,Air flow Range in door dry, in door wet and evap out let dry bulb . I recently starting using the Dan Foss slider and it’s proved to be a big help for PT conversions. But I liked the step by step pyramid diagram you demonstrated for evaluating the situation. Just another tool I will use now that makes my job easier and alot less frustrating on the times ut can be .

Thanks guys at HVAC school .

Sincerely,

Sean McDermott

That was well said . One thing I find so easy these days regarding collecting data to determine the source of problem causing issues is that it can be done in relatively a short amount of time.. I have 3 apps on my phone for collecting and calculating Wet bulb/Dry bulb temps, SUBCOOLING/SUPERHEAT values ,Air flow Range in door dry, in door wet and evap out let dry bulb . I recently starting using the Dan Foss slider and it’s proved to be a big help for PT conversions. But I liked the step by step pyramid diagram you demonstrated for evaluating the situation. Just another tool I will use now that makes my job easier and alot less frustrating on the times ut can be .

Thanks guys at HVAC school .

Sincerely,

Sean McDermott

Cialis sans ordonnance pas cher [url=http://tadalmed.com/#]cialis sans ordonnance[/url] Achat Cialis en ligne fiable tadalmed.com

Cialis sans ordonnance pas cher [url=http://tadalmed.com/#]cialis sans ordonnance[/url] Achat Cialis en ligne fiable tadalmed.com

Tadalafil sans ordonnance en ligne Acheter Cialis or Tadalafil 20 mg prix en pharmacie

https://cse.google.td/url?sa=t&url=https://tadalmed.com Tadalafil sans ordonnance en ligne

[url=https://www.google.com.ni/url?sa=t&url=https://tadalmed.com]Acheter Cialis[/url] cialis generique and [url=http://www.xgmoli.com/bbs/home.php?mod=space&uid=7214]Cialis generique prix[/url] Cialis sans ordonnance pas cher

Tadalafil sans ordonnance en ligne Acheter Cialis or Tadalafil 20 mg prix en pharmacie

https://cse.google.td/url?sa=t&url=https://tadalmed.com Tadalafil sans ordonnance en ligne

[url=https://www.google.com.ni/url?sa=t&url=https://tadalmed.com]Acheter Cialis[/url] cialis generique and [url=http://www.xgmoli.com/bbs/home.php?mod=space&uid=7214]Cialis generique prix[/url] Cialis sans ordonnance pas cher

kamagra 100mg prix: kamagra en ligne – Kamagra pharmacie en ligne

kamagra 100mg prix: kamagra en ligne – Kamagra pharmacie en ligne

acheter mГ©dicament en ligne sans ordonnance: Meilleure pharmacie en ligne – Pharmacie en ligne livraison Europe pharmafst.com

acheter mГ©dicament en ligne sans ordonnance: Meilleure pharmacie en ligne – Pharmacie en ligne livraison Europe pharmafst.com

Tadalafil achat en ligne: Tadalafil 20 mg prix sans ordonnance – Achat Cialis en ligne fiable tadalmed.shop

Tadalafil achat en ligne: Tadalafil 20 mg prix sans ordonnance – Achat Cialis en ligne fiable tadalmed.shop

acheter kamagra site fiable [url=https://kamagraprix.com/#]Achetez vos kamagra medicaments[/url] achat kamagra

acheter kamagra site fiable [url=https://kamagraprix.com/#]Achetez vos kamagra medicaments[/url] achat kamagra

kamagra livraison 24h kamagra gel or Kamagra Commander maintenant

https://www.google.com.om/url?q=https://kamagraprix.shop kamagra 100mg prix

[url=https://maps.google.mn/url?q=https://kamagraprix.shop]Kamagra pharmacie en ligne[/url] acheter kamagra site fiable and [url=http://lzdsxxb.com/home.php?mod=space&uid=4353135]Kamagra Oral Jelly pas cher[/url] kamagra en ligne

kamagra livraison 24h kamagra gel or Kamagra Commander maintenant

https://www.google.com.om/url?q=https://kamagraprix.shop kamagra 100mg prix

[url=https://maps.google.mn/url?q=https://kamagraprix.shop]Kamagra pharmacie en ligne[/url] acheter kamagra site fiable and [url=http://lzdsxxb.com/home.php?mod=space&uid=4353135]Kamagra Oral Jelly pas cher[/url] kamagra en ligne

Pharmacie sans ordonnance: Pharmacies en ligne certifiees – п»їpharmacie en ligne france pharmafst.com

Pharmacie sans ordonnance: Pharmacies en ligne certifiees – п»їpharmacie en ligne france pharmafst.com

olympe casino en ligne: olympe casino en ligne – olympe

olympe casino en ligne: olympe casino en ligne – olympe

To leave a comment, you need to log in.

Log In