Get Tech Tips

Subscribe to free tech tips.

Troubleshooting For HVAC/R – Gathering Data

This article is part 3 in a 5-part series by Senior Refrigeration and HVAC Technician Jeremy Smith.

Let's start with step#1 in the flowchart:

Gather data.

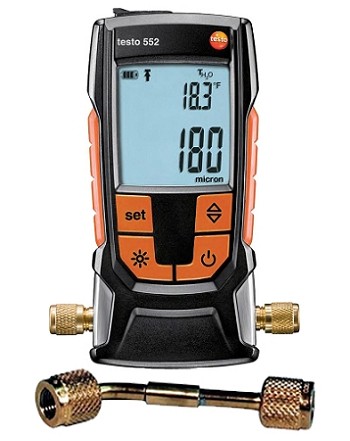

This is why we spend money on those fancy digital manifolds, shiny electrical meters, and other gadgets, widgets, and doodads. It isn't to brag about them on Facebook; it's to find problems better and faster than someone else.

So, before you start trying to change things, start by gathering and recording data. Inspect filters, inspect coils. Look over the wiring. Check your voltages, resistances, airflow, pressure readings, temperature readings. Locate any open switches in the control circuit, and try to determine WHY that switch is open. A pocket notebook is nice, but for larger problems, I've taken to carrying a full-sized college-type notebook.

This gives me more room on the page to write my notes, draw pictures, scribble thoughts, and observations about the equipment I'm working on.

Write down every measurement and reading. EVERYTHING. Even if you find that capacitor blown up and you “just know” that's the problem, take your time and keep looking.

Before we leave the Data Gathering step, we do need to take whatever steps are necessary to get the equipment running if it isn't already and gather another set of data.

Once you have all this data together, we can proceed to Step #2: Analysis.

—Jeremy

If you've missed the previous parts of this series, here are the links to Part 1 and Part 2.

Comments

If you are to properly evaluate air conditioning problems you need to gather data. That means lots of data you should not make an evaluation just on a couple readings such as suction pressure and superheat. You may charge a fixed metering device by superheat but to evaluate problems you need not just those two readings but liquid and vapor line inside and outside readings, return / supply air dry and wet bulb temperatures, etc. Return air temperature at the return grilles and at the indoor unit.

If you are to properly evaluate air conditioning problems you need to gather data. That means lots of data you should not make an evaluation just on a couple readings such as suction pressure and superheat. You may charge a fixed metering device by superheat but to evaluate problems you need not just those two readings but liquid and vapor line inside and outside readings, return / supply air dry and wet bulb temperatures, etc. Return air temperature at the return grilles and at the indoor unit.

kamagra pas cher: Kamagra Commander maintenant – acheter kamagra site fiable

kamagra pas cher: Kamagra Commander maintenant – acheter kamagra site fiable

pharmacie en ligne france livraison internationale pharmacie en ligne fiable or Pharmacie sans ordonnance

https://images.google.si/url?sa=t&url=https://pharmafst.com pharmacie en ligne livraison europe

[url=https://maps.google.kg/url?q=https://pharmafst.com]pharmacie en ligne sans ordonnance[/url] pharmacie en ligne livraison europe and [url=http://umsr.fgpzq.online/home.php?mod=space&uid=10556]pharmacie en ligne france fiable[/url] pharmacie en ligne pas cher

pharmacie en ligne france livraison internationale pharmacie en ligne fiable or Pharmacie sans ordonnance

https://images.google.si/url?sa=t&url=https://pharmafst.com pharmacie en ligne livraison europe

[url=https://maps.google.kg/url?q=https://pharmafst.com]pharmacie en ligne sans ordonnance[/url] pharmacie en ligne livraison europe and [url=http://umsr.fgpzq.online/home.php?mod=space&uid=10556]pharmacie en ligne france fiable[/url] pharmacie en ligne pas cher

kamagra en ligne: Kamagra Oral Jelly pas cher – Acheter Kamagra site fiable

kamagra en ligne: Kamagra Oral Jelly pas cher – Acheter Kamagra site fiable

pharmacie en ligne fiable: Livraison rapide – vente de mГ©dicament en ligne pharmafst.com

pharmacie en ligne fiable: Livraison rapide – vente de mГ©dicament en ligne pharmafst.com

Tadalafil 20 mg prix en pharmacie: Cialis sans ordonnance pas cher – Acheter Cialis 20 mg pas cher tadalmed.shop

Tadalafil 20 mg prix en pharmacie: Cialis sans ordonnance pas cher – Acheter Cialis 20 mg pas cher tadalmed.shop

kamagra pas cher: Kamagra Oral Jelly pas cher – Kamagra Commander maintenant

kamagra pas cher: Kamagra Oral Jelly pas cher – Kamagra Commander maintenant

Acheter Viagra Cialis sans ordonnance: cialis generique – Cialis sans ordonnance 24h tadalmed.shop

Acheter Viagra Cialis sans ordonnance: cialis generique – Cialis sans ordonnance 24h tadalmed.shop

olympe: olympe casino – casino olympe

olympe: olympe casino – casino olympe

Remember subcooling for TXVs.

Remember subcooling for TXVs.

Achetez vos kamagra medicaments: Kamagra Oral Jelly pas cher – kamagra pas cher

Achetez vos kamagra medicaments: Kamagra Oral Jelly pas cher – kamagra pas cher

To leave a comment, you need to log in.

Log In