Get Tech Tips

Subscribe to free tech tips.

Refrigerant Charging Basics For Air Conditioning & Heat Pump Systems

Before I start on this one…

At HVAC School, we focus on a wide range of topics. Many of them are very basic. My experience as a trainer for over 20 years has taught me that no matter what I assume others SHOULD know, it doesn't change the fact that they often do not. This write-up is very basic, but you may find that some of the content will be useful for you to give apprentices or junior techs, or it may give you a new idea of how to explain it to them—or maybe not. Either way, I feel obligated to cover even the most basic concepts in the trade to help ensure that nothing gets missed.

Thanks for understanding.

Before reading this, you need to understand some of the terms surrounding air conditioning charging and diagnosis, specifically the term saturation.

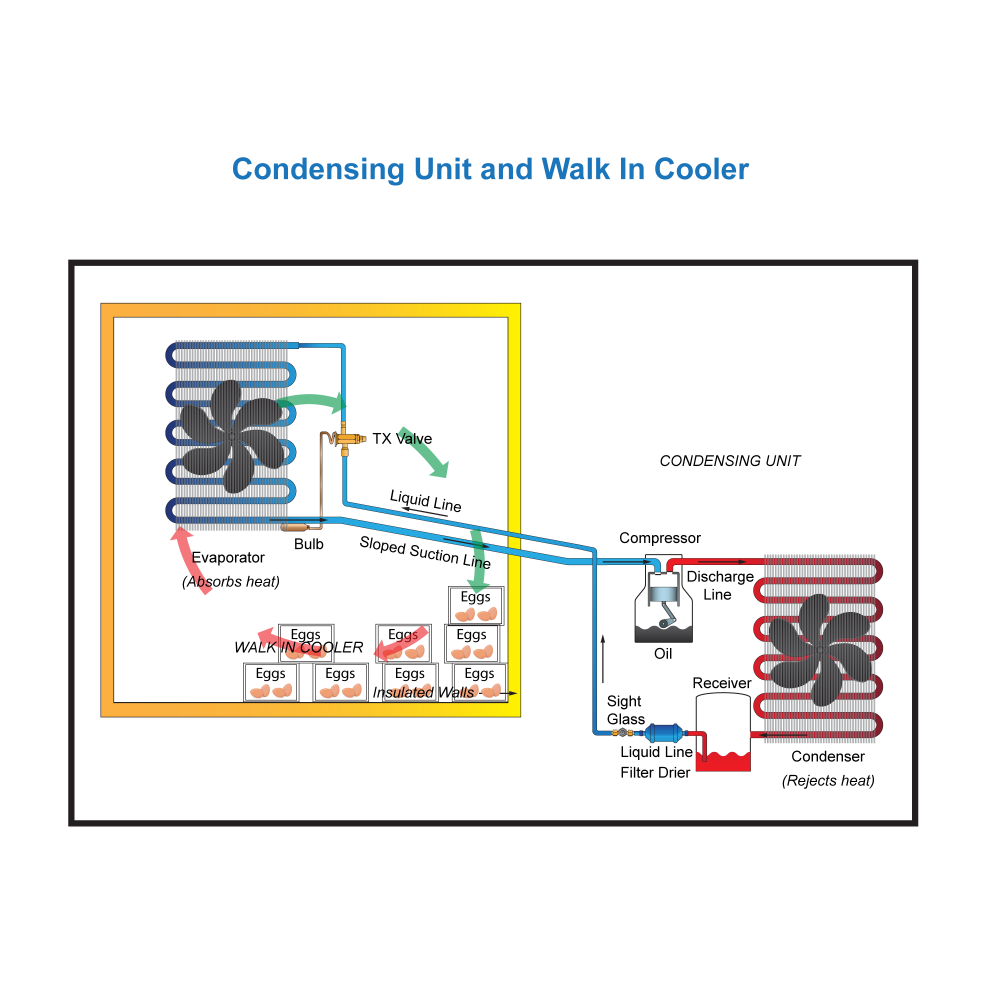

Next, you need to know something about the basic refrigerant circuit. I suggest that you understand these words and concepts before you ever attempt to charge an air conditioner; click on the links to start reading about the topics and find a solid starting point.

Many who start here may ask, “What should my pressures be?” That is NOT how you charge a system, so if you are reading this to try and find that answer, just be aware that it isn't that simple.

READ THE MANUFACTURER SPECS ON PROPER CHARGING FOR THE MODEL YOU ARE WORKING ON FIRST WHENEVER POSSIBLE.

Charging Basics

To set a proper charge on an A/C system, you must first know the type of metering device. The piston/fixed orifice type system primarily uses the superheat method, and the TXV/EEV primarily uses the subcooling method. When setting a charge, it is always preferable to set the charge in cool mode. Whether you set the charge in heat or cool mode, you should always follow the manufacturer's recommended charging specifications. This section will discuss manufacturer-recommended charging and some indicators that you have set a proper charge in heat mode.

But first, there are some things that trump these guidelines and should make you stop and perform more diagnostics.

A properly running A/C system with indoor and outdoor temperatures above 68 degrees will have a suction saturation above 32 degrees (freezing). Don't leave a system with a below 32˚ saturation suction without performing more diagnostics, even if the superheat/subcool looks correct.

If you see a liquid line pressure that is more than 30 degrees saturation above outdoor temperature (like a 440 PSI liquid pressure on an R410a system on a 90-degree day), do not proceed until you have further addressed the possible causes of high head, regardless of what the superheat or subcool might be reading.

Always purge your hoses to prevent introducing air into the system, and never mix gauges when using low-loss fittings if you're working on systems with different types of refrigerants.

Charge in the liquid phase (tank upside down) and add the refrigerant slowly and carefully to ensure you do not flood/slug the compressor with liquid refrigerant. You can do this by watching your manifold sight glass or using a special liquid-preventing adapter, such as the Imperial 535-C Kwik Charge.

These precautions will prevent causing system damage.

Also, at a minimum, perform a full visual inspection of the equipment, including:

- Filter inspection

- Checking the blower wheel

- Checking evaporator coil

- Checking condenser coil cleanliness

- Making sure the system is wired properly and running in the correct mode

Note: This guide covers only the basics of refrigerant charging. There are innumerable conditions that are not related to the refrigerant charge but can still alter refrigerant pressures, superheat, subcool, and saturation. This guide is not intended to cover the complete diagnosis of the refrigerant circuit.

Superheat Charging

To charge a system using superheat, you will need to monitor the actual temperature of the low-pressure suction line, the saturation temperature of the low-side suction gauge, and the indoor and outdoor temperatures entering the unit(s).

Most, if not all, manufacturers have a charging chart available with their respective units. With the information you have gathered on indoor and outdoor temperatures, you can calculate the recommended superheat. In a pinch, you can also use a superheat calculator, such as the Trane superheat calculator, a free app like our superheat calculator (top left), or the MeasureQuick app. A good calculator will require that you determine the wet-bulb temperature in the return air stream. Without a sling, digital psychrometer, or hygrometer, you will not be able to determine wet-bulb temperature.

Once you know the target superheat, you can adjust the system charge to hit it. Let's say the recommended superheat was 18 degrees; you would add/remove refrigerant to the system until the actual temperature of the suction line was 18 degrees above the indicated saturation temperature from your low-pressure gauge. Adding charge will decrease the superheat, and recovering refrigerant will increase the superheat.

Subcool Charging

To charge a system using subcool, you will need to monitor the actual temperature of the liquid line and indicated saturation temperature on the high-pressure gauge. Information on the entering temperatures is not necessary to charge the unit by the subcooling method.

Most manufacturers have recommended subcool charging information with the unit if it is designed for a TXV (TEV). If there is no information on the unit for some reason, or if it has worn off, you can set a typical residential air conditioner charge to 10 to 12 degrees of subcooling, which is a relatively safe range to use.

Let's say, for example, the manufacturer's recommended subcool is 14 degrees. You would add enough refrigerant to the system so that the actual temperature of the liquid line was 14 degrees less than the saturation temperature, as indicated on the high-pressure gauge for that particular refrigerant. Adding more refrigerant will increase the subcool reading, and recovering refrigerant will decrease the subcool reading.

Approach Method

Lennox factory information asks that we charge by the approach method on TXV systems. I suggest charging to at least a 6-degree subcool before even attempting to calculate the approach method.

The approach method is a calculation based on the relationship of liquid line temperature to the outdoor temperature. To calculate the approach, subtract the outdoor ambient from the actual liquid line temperature. The outdoor temperature used to calculate the approach should always be taken in the shade and away from the hot condenser discharge air. To increase the approach differential, you would remove refrigerant; you would add refrigerant to decrease it.

Some Lennox heat pump systems come with a subcool chart next to the approach chart. This subcool chart is for <65˚. This means the subcool chart is only valid when the outdoor temperature is below 65˚. Follow the instructions on the unit carefully when charging in subcooling in <65˚ temperatures. The method requires that you block sections of the coil to achieve higher head pressures before setting by subcooling.

Heat Mode Charging for Heat Pumps

In most, if not all, cases, you will charge a unit in heat mode according to the manufacturer’s recommendations. In those cases where no information is available, there are other indicators that you may use to set a proper charge in heat mode.

First, make sure you switch your hoses so that the suction gauge is reading off of the “common suction” port that taps in between the compressor and the reversing valve. You may put your high side gauge on either the discharge or liquid (on most systems), depending on what you are checking.

Before doing any heat mode charging, use common sense. If installing a new system, the best bet is to calculate line distance and weigh in any additional charge before moving on to the detailed testing phase.

The first one is the 100˚ over ambient discharge temperature rule. The general rule is that a properly charged unit will have a discharge line temperature of 100˚ above the outdoor ambient temperature, but this is only a rule of thumb and cannot be relied upon. If the discharge line is too hot, you would add refrigerant, which would lower the discharge temperature. Alternatively, if the discharge line were too cool, you would remove some refrigerant to raise the discharge temperature. This rule is to be used only as an indicator and, in some instances, may not be accurate given some other factors such as dirty coils, excessive superheated refrigerant entering the compressor, etc.

Another common rule of thumb is that suction pressure will be close to the outdoor temperature in an R-22 system. This rule is totally a fluke and has no scientific basis other than it just generally tends to work out that way. On a properly functioning R-22 system running in heat mode in 40-degree weather, the suction pressure tends to be around 40 PSIG. This guideline obviously doesn't work on an R-410A system or any other refrigerant.

A more applicable guideline is 20-25˚ suction saturation below outdoor ambient temperature. If it is 50˚ outside, the suction saturation temperature would generally be between 25˚ and 30˚ on a functioning system.

Remember that in heat mode, the colder it gets outside, the lower the suction pressure, and the hotter it gets inside, the higher the head pressure. Since the roles of the coil are reversed in heat mode, if you notice an abnormally high head pressure, it may be due to a dirty air filter or evaporator coil. A dirty condenser coil would cause the suction pressure to drop below normal. It may also cause superheat problems.

Once a charge is set, whether by manufacturer specification or an alternative method, you can still verify the subcool and superheat on the unit in some cases. Do not confuse the superheat or subcool methods recommended by the manufacturer when running in heat mode. These are only used for setting the charge in cooling mode and not in heat. Look for heat mode-specific or low ambient guidelines.

Finally—and most importantly—is ALWAYS TEST EVERYTHING. Airflow, delta T, superheat, subcool, suction pressure, head pressure, amps, incoming voltage, filter, etc.

Read manufacturers' specs and understand the units you are working on. Only then will guidelines and rules of thumb help instead of hinder you.

—Bryan

Comments

Very good readings!!!! Thanks for all your hard work.

Very good readings!!!! Thanks for all your hard work.

I am glad i took the time to read you article. well written.. thanks.

I am glad i took the time to read you article. well written.. thanks.

Great article. The way you explained this helped me to really visualize my approach when the time comes. I’m an installer of 2 years and in school now for my journeymens. This will help me articulate with my coworker and see about running thru the process myself, appreciate it.

Great article. The way you explained this helped me to really visualize my approach when the time comes. I’m an installer of 2 years and in school now for my journeymens. This will help me articulate with my coworker and see about running thru the process myself, appreciate it.

Really helpful

Thank you

Really helpful

Thank you

In heating, does the 20-25 condenser split (or evap, rather, in heating) change with the seer ratings?

In heating, does the 20-25 condenser split (or evap, rather, in heating) change with the seer ratings?

IQOS представляет собой технологичное решение для работы с нагреваемым табаком.

В отличие от классического курения, здесь используется другой способ обработки табака.

Часть людей отмечают, что такой формат характеризуется иным восприятием.

Устройство отличается простым управлением, что делает его подходящим для повседневного применения.

Современный дизайн позволяет IQOS выглядеть стильно.

Производитель уделяет внимание деталям конструкции, что повышает комфорт эксплуатации.

Своевременная очистка помогает поддерживать стабильную работу устройства.

В итоге, IQOS остаётся одним из вариантов альтернативных решений для тех, кто рассматривает такие системы.

https://terea777.shop/khotylevo/catalog

IQOS представляет собой технологичное решение для работы с нагреваемым табаком.

В отличие от классического курения, здесь используется другой способ обработки табака.

Часть людей отмечают, что такой формат характеризуется иным восприятием.

Устройство отличается простым управлением, что делает его подходящим для повседневного применения.

Современный дизайн позволяет IQOS выглядеть стильно.

Производитель уделяет внимание деталям конструкции, что повышает комфорт эксплуатации.

Своевременная очистка помогает поддерживать стабильную работу устройства.

В итоге, IQOS остаётся одним из вариантов альтернативных решений для тех, кто рассматривает такие системы.

https://terea777.shop/khotylevo/catalog

Creative photography often focuses on highlighting the aesthetics of the human form.

It is about composition rather than exposure.

Skilled photographers use natural tones to reflect mood.

Such images celebrate delicacy and personality.

https://xnudes.ai/

Each photo aims to evoke feelings through movement.

The goal is to present inner grace in an respectful way.

Observers often admire such work for its creativity.

This style of photography combines technique and sensitivity into something truly timeless.

Creative photography often focuses on highlighting the aesthetics of the human form.

It is about composition rather than exposure.

Skilled photographers use natural tones to reflect mood.

Such images celebrate delicacy and personality.

https://xnudes.ai/

Each photo aims to evoke feelings through movement.

The goal is to present inner grace in an respectful way.

Observers often admire such work for its creativity.

This style of photography combines technique and sensitivity into something truly timeless.

To leave a comment, you need to log in.

Log In