Get Tech Tips

Subscribe to free tech tips.

Refrigerant Basics

A refrigerant is anything we use to move heat from one place to another using the compression refrigeration circuit. However, the history of refrigerants and the different kinds is quite diverse and interesting.

Have you ever noticed how your skin feels cool after you apply some rubbing alcohol to it? For a long time, scientists and inventors experimented with substances that evaporated easily at atmospheric pressure, like ether and alcohol. They noticed that these substances cooled the surface they left when they evaporated away. It was understood that substances remove heat as they boil (change from liquid to vapor) because that is one way our bodies reject heat while sweating. As the sweat evaporates, it removes heat from our skin, leaving us cooler.

This is an “open” process; the alcohol, ether, or sweat leaves as it cools, so you always need more to keep the process going. The trick was to create a process that could be done repeatedly without losing the “refrigerant” to the atmosphere.

Compression Refrigeration

A physician named John Gorrie built one of the first compression refrigeration machines, and it used air as the refrigerant. By compressing the air, it would increase in temperature, and heat could be rejected from it. He would then “rarify” or depressurize the air, dropping the temperature and allowing heat to be absorbed into the air from the water. The machine could then—eventually—produce ice.

There were several issues with Dr. Gorrie's design. One big issue was that while he was using compression and expansion, he wasn't using the power of evaporation to increase the amount of heat that could be moved.

It wasn't long before others began using refrigerants like ammonia, CO2, sulfur dioxide, and methyl chloride using the same compressing and expanding that Dr. Gorrie used but with the added benefit of boiling (evaporating) the refrigerant in the evaporator to absorb a maximum amount of heat as well as the change back to liquid (condensing) in the condenser. (There were also some forms of refrigeration that did NOT rely on compression but still used refrigerants like ammonia.)

As times have progressed, refrigerants have changed to make them safer for humans and the environment. Nowadays, refrigerants and refrigerant handling in the USA are regulated by EPA Section 608. In order to handle and service air conditioning and refrigeration in the USA legally, you need to pass the EPA 608 exam and carry the certification card.

So, what makes a good refrigerant?

A Good Refrigerant:

- Has high latent heat of vaporization (it moves a lot of heat per lb when it boils)

- Boils and condenses at temperatures we can easily manipulate with compression (the pressures work)

- Mixes with the oil appropriately so that the oil can do the job of lubricating the compressor and return.

- Doesn't blow stuff up or catch on fire

- Doesn't poison people

- Doesn't hurt the environment

That pretty much sums it up.

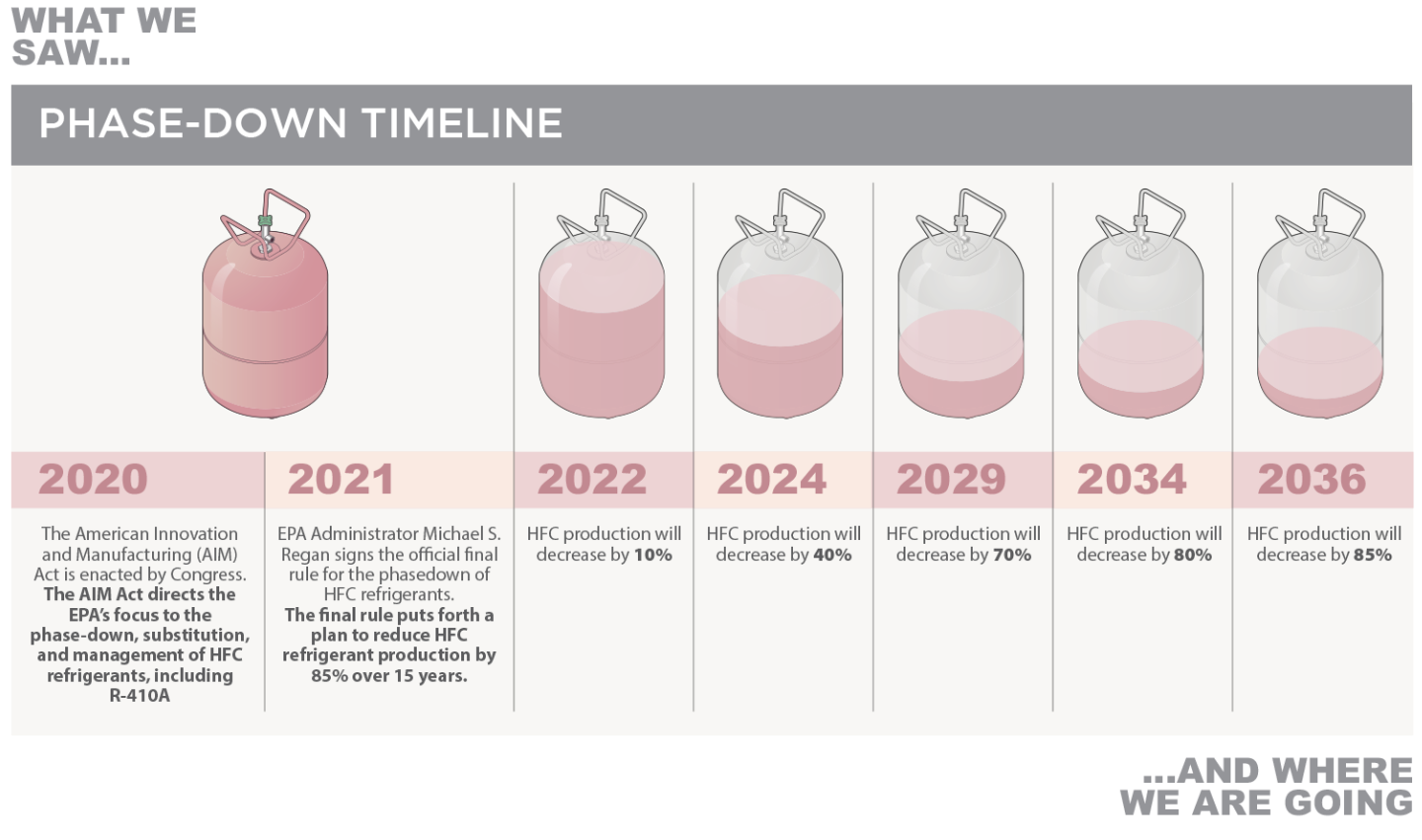

Because we have seen increased environmental regulations over the last 25 years, there has been a push to find “good” refrigerants that meet the above criteria, even if it means going into the flammable and toxic spectrum.

Flammability and Toxicity Classifications

Thankfully, refrigerants are well-marked. So long as we pay attention and follow best practices, there shouldn't be any issues.

The markings are pretty simple:

- Class A refrigerants have low toxicity

- Class B refrigerants have high toxicity

- Class 1 refrigerants have low flammability

- Class 2L refrigerants are only “mildly” flammable

- Class 2 refrigerants are low flammability but higher than 2L

- Class 3 refrigerants are highly flammable

The most common toxic refrigerant is ammonia, and you would generally only find it in old appliances or large industrial applications.

Propane (R290) is a flammable refrigerant and is becoming quite popular in small self-contained refrigeration units like vending machines and reach-in coolers. These propane units will be very clearly marked and should be handled with extreme caution, especially when electrical sparks or open flames are or could be present.

—Bryan

P.S. – For more information on the emerging A2L refrigerants, check out Don Gillis's article, our podcast episode about A2Ls with Jason Obrzut, or AHRI's Safe Refrigerant Transition Task Force.

Comments

To leave a comment, you need to log in.

Log In