Get Tech Tips

Subscribe to free tech tips.

A Case For Wireless Refrigerant Probes

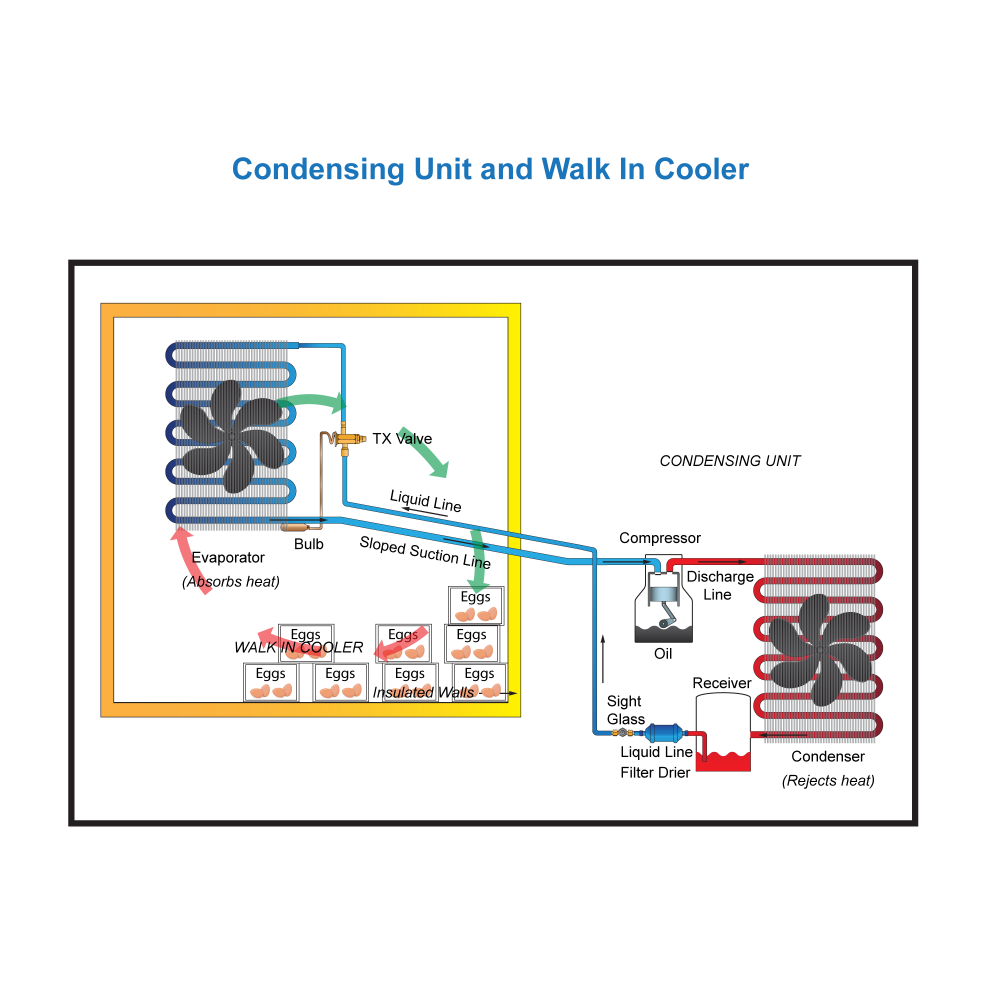

Photo by Brad Hicks at HVAC in SC

Right off the top, let me state something loud and clear:

The tool does not make the tech.

Let that sink in before you move on.

A good tech has a solid understanding of WHY they are doing what they are doing, the basic math of the trade, and enough experience to spot most problems with their senses before they reach for a tool at all.

However, there are some cases when you need a specialty tool. You need it so much that you cannot do your job without a good one (leak detectors and micron gauges come to mind). In some rare cases, the cheap and high-end versions of a tool are so different that you are at a real disadvantage if you don't have the quality version.

Multiple manufacturers have come out with wireless pressure probe technology. Until recently, I couldn't get over the fact that you cannot use these probes for charging and recovery. Why would you want a separate toolset in addition to your gauge manifold?

Well, I think I finally get it. Here are some reasons that others have given me that have me seeing the light:

Low Loss

One big advantage is you can use the probes to check a system charge with no hose losses. That's huge for systems with a critical charge (think ice machines), when doing regular preventative maintenance, and when hooking up to the system to check it during a service call unrelated to charge. Keeping all that charge in the system is a service to the customer and helps save expensive refrigerant. You can keep some 90-degree core depressing adaptors or some short hoses to help connect in tight spots.

Additional Readings

With smart probes, you can now check additional temperature and pressure readings without the need to move your hoses around when you have a manifold attached. You can check liquid and discharge pressure simultaneously, check temperature drop across a liquid line, or superheat gains across the suction. That's all great data that the wireless smart probes can help with.

Hard to Get Readings

Now, this one was the one that tipped the scales for me. It was brought to my attention by tech Joe Shearer (thanks, Joe). You can use smart temperature sensors (Testo 115i) to get readings on running systems in spots where wired probes can be almost impossible. Reading superheat inside a heat pump condensing unit during heat mode, reading temperature differential across a reversing valve, and taking discharge temperature at the compressor are all examples where the smart temperature probes come in really handy.

The MeasureQuick App

Testo is one of the first tools to work with the new MeasureQuick app for full system diagnosis, unlike anything you have seen. This may feel like a pitch, but working with MeasureQuick—as well as the great price—makes the Testo Smart Probes a very attractive option.

So, I think you may want to think about smart probes and if they might help you once you are already confident enough to understand why and how you would use them to be a better tech.

—Bryan

P.S. – If you are interested, you may consider going HERE and looking at the Testo smart probes. If you buy from TruTech Tools, use the offer code “getschooled” for 8% off your order.

Comments

Thanks for the great article. Another reason for any of the wireless tools is to get out of the Arc Flash boundary while the equipment is running or energized. Because of the requirements in the latest NFPA 70e a worker needs CAT 2 or better arc flash (AF) gear on while standing in front of live circuits, and on a lot of HVAC equipment attaching hoses prevents the reinstallation of the panel that covers the live electrical. By using the wireless tools a tech can shut down the equipment and confirm the power has been removed while wearing the AF gear, then remove the AF gear during testing because the panels can be put back on.

Thanks for the great article. Another reason for any of the wireless tools is to get out of the Arc Flash boundary while the equipment is running or energized. Because of the requirements in the latest NFPA 70e a worker needs CAT 2 or better arc flash (AF) gear on while standing in front of live circuits, and on a lot of HVAC equipment attaching hoses prevents the reinstallation of the panel that covers the live electrical. By using the wireless tools a tech can shut down the equipment and confirm the power has been removed while wearing the AF gear, then remove the AF gear during testing because the panels can be put back on.

I can add refrigerant using my smart probes. I have two of the six inch hoses with ball vales I simply add my valve core removal tool onto the one on the low side put my probe on the side port and a hose from the tank to the tool and add by simply opening the valve on the tool

I can add refrigerant using my smart probes. I have two of the six inch hoses with ball vales I simply add my valve core removal tool onto the one on the low side put my probe on the side port and a hose from the tank to the tool and add by simply opening the valve on the tool

That’s exactly how we’ve got ours set up as well. I even found a C&D thumbscrew valve (https://cdvalve.com/products/cd5050/) for the high side since the Testo depressor sticks out a hair too far and is not adjustable.

That’s exactly how we’ve got ours set up as well. I even found a C&D thumbscrew valve (https://cdvalve.com/products/cd5050/) for the high side since the Testo depressor sticks out a hair too far and is not adjustable.

I use the Fieldpiece smart probes and I love them. More times than not I am at least 100 feet away from the other piece of my equipment. The AHU or FCU is in the penthouse and the condensing unit is way out on the roof. I also use the MeasureQuick app, and Jim B. and the guys at tru tech tools have been great. Being an Engineer continuing education is a big thing for me. I appreciate you and Jim and the hard work you put into the HVACR field. I also enjoy the emails and videos and forward them on to my other techs. Keep up the good work and know that I am not the only person grateful for your efforts.

I use the Fieldpiece smart probes and I love them. More times than not I am at least 100 feet away from the other piece of my equipment. The AHU or FCU is in the penthouse and the condensing unit is way out on the roof. I also use the MeasureQuick app, and Jim B. and the guys at tru tech tools have been great. Being an Engineer continuing education is a big thing for me. I appreciate you and Jim and the hard work you put into the HVACR field. I also enjoy the emails and videos and forward them on to my other techs. Keep up the good work and know that I am not the only person grateful for your efforts.

To leave a comment, you need to log in.

Log In