Get Tech Tips

Subscribe to free tech tips.

Why Measuring Static First Isn’t Always Productive

There is a big move in residential and light commercial HVAC toward measuring static pressure regularly during commissioning, service, and maintenance. Don't get me wrong…

Measuring static pressure is VERY important.

The challenge comes in when techs begin taking measurements without understanding where to take them, what they mean, or worse: they use measurements as an excuse not to do a proper visual, common-sense inspection.

So, before we go on, let's cut to the chase. You need to use your vision to inspect blower wheels, blower taps and settings, blower direction, belts, pulleys, evaporator coils, filters, and condenser coils, as well as look for any other abnormal return or condenser restrictions.

Do this BEFORE you take detailed measurements, and you will save yourself a lot of time and heartache.

So, what is “static pressure” anyway?

Think of the air side of the system as a balloon. Static pressure is the inflating (positive) or deflating (negative) pressure against the walls of the ducts/fan coil/furnace in relationship to another point, which is usually atmospheric pressure of 14.7 PSIA (at sea level) or 0 PSIA.

When you blow up a balloon, there is positive pressure against all sides inside the balloon in relation to the atmospheric pressure around the balloon.

Static pressure in residential and light commercial HVAC is generally measured in inches of water column (“wc). We often measure it with an accurate digital manometer zeroed out to atmospheric pressure before use.

Static pressure is NOT airflow. You could have static pressure and no airflow whatsoever. If you think of it in electrical terms, you can read voltage (potential) between two points and have no actual movement of electrons. It is a measure of the difference in energy states between two points, not a measure of quantity.

If you took a blower, attached a duct to it, blocked the end of the duct with a cap, and turned the blower on, you would have 0 CFM of airflow in the duct and very high static pressure. The exact amount of static pressure would be based on the ability of that particular blower motor and wheel to build up pressure.

So, when we measure static, we measure pressure in the duct system, not flow. (I also taught a class about static pressure basics. If you think that might help you understand static pressure better, you can watch that video HERE.)

Why does the motor matter?

The more powerful the motor, the more pressure it can create and the more pressure/resistance it can overcome.

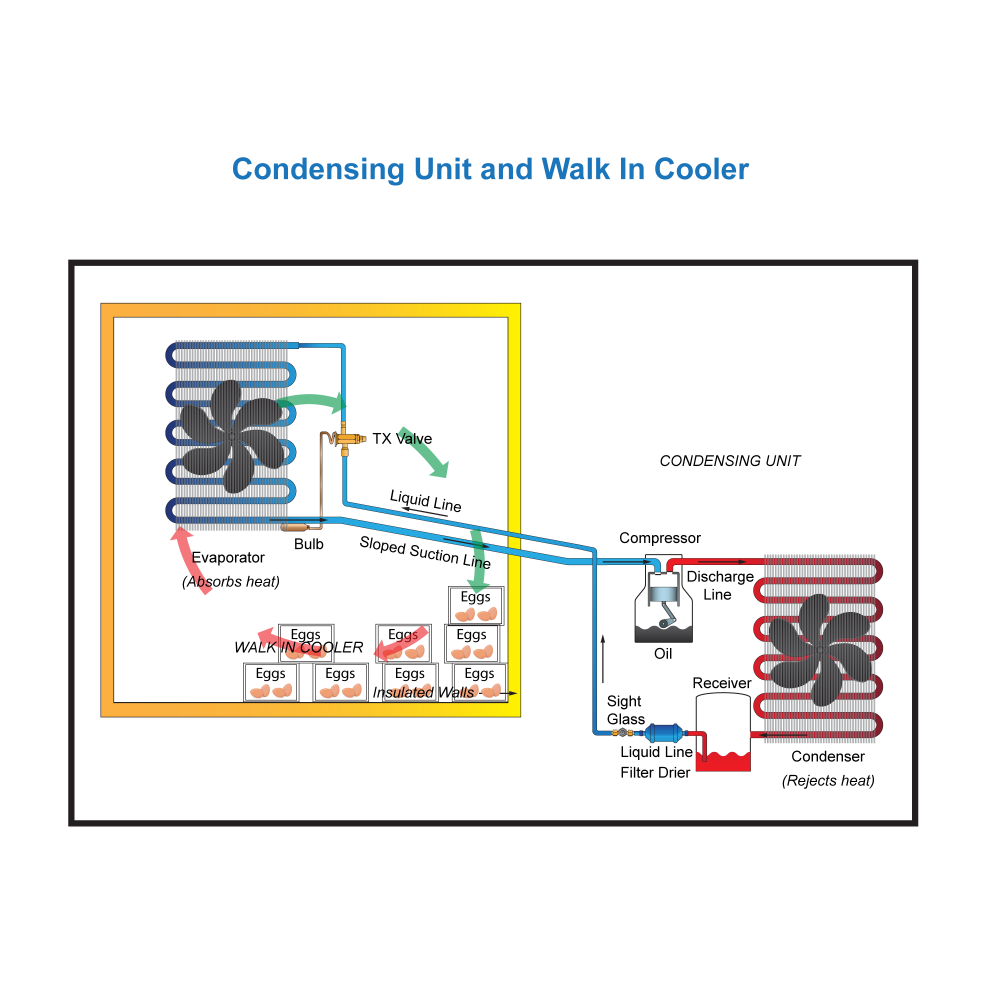

Think of a blower motor a bit like a compressor; when it is off, both the inlet and outlet pressure are the same. In the case of a compressor, the pressure when off will be the static pressure of the refrigerant (let's say 132 PSIG static pressure for R22 at 75° ambient). In the case of a blower, it will be atmospheric pressure.

When the compressor turns on, the suction pressure drops below 132 PSIG, and the head pressure rises above 132 PSIG. The compressor creates this difference in pressure both above and below the static saturated refrigerant pressure.

When a blower turns on, it also drops the pressure of the return side below atmospheric pressure (14.7 PSIA), and it increases the supply side pressure above atmospheric pressure.

We measure this static pressure at various points to find out how much resistance there is to airflow at various points in the system.

For example, we may measure the pressure drop across the evaporator, the filter, or a particular run of duct or across a fire damper (to see if it's slammed shut).

We also measure near the top and bottom of the appliance (furnace or fan coil) to find the total external static pressure (TESP), which helps us calculate airflow when we compare it to fan tables. It also helps us understand if we duct or system issues.

On a brand-new, perfectly functioning system, this works great.

But on an older system with a dirty blower wheel or a fan coil with a dirty coil, this no longer serves its original purpose.

Potential problems and what to do about them

If the blower wheel is dirty, the blower loses its ability to move air effectively, therefore also losing its ability to create the pressure differential between the return and supply.

We are trained to think that low static = good and high static = bad.

In the case of a dirty blower wheel or a clogged evap on a fan coil, the TESP will be LOW, and there will still be low airflow (low CFM).

As far as the refrigerant circuit and capacity are concerned, the static pressure is meaningless; it is all a matter of how many CFM of air is traveling over the coil surface area. We use static pressure as a diagnostic and benchmarking tool when taken together with an understanding of the system, blower specs and settings, and duct design. Static pressure by itself means very little in the same way that measuring voltage and head pressure mean very little by themselves.

The point of this article is not to downplay the importance of static pressure or to explain how to measure it. The point is to remind you of two important facts:

- Check your blower wheel, blower direction, coils, filters, blower settings, and other obvious airflow restrictions and issues first.

- Before measuring your static, think carefully about where you are placing your probes and what you expect to see/what you are diagnosing with the measurement.

—Bryan

Extras

For a detailed explanation of static pressure, you can go HERE.

You can also watch a great video by Jim Bergmann using a Testo manometer HERE or Corbett Lundsford on static HERE.

Neil Comparetto also wrote an excellent article about measuring static pressure HERE.

Rick Streacker gave a great presentation on the impacts of static pressure on fan and blower motors at the 2022 HVACR Training Symposium. You can watch it HERE.

Comments

In Jim’s video he indicates to point the static pressure probe’s tip “up”, in the same direction of airflow and on Corbett’s he specifies to point it “down” into the airflow.

I have always done it the way Corbett does it in this video but, is it wrong?

In Jim’s video he indicates to point the static pressure probe’s tip “up”, in the same direction of airflow and on Corbett’s he specifies to point it “down” into the airflow.

I have always done it the way Corbett does it in this video but, is it wrong?

Acheter Cialis: Cialis sans ordonnance pas cher – Pharmacie en ligne Cialis sans ordonnance tadalmed.shop

Acheter Cialis: Cialis sans ordonnance pas cher – Pharmacie en ligne Cialis sans ordonnance tadalmed.shop

pharmacie en ligne france pas cher [url=http://pharmafst.com/#]Meilleure pharmacie en ligne[/url] pharmacie en ligne france livraison internationale pharmafst.shop

pharmacie en ligne france pas cher [url=http://pharmafst.com/#]Meilleure pharmacie en ligne[/url] pharmacie en ligne france livraison internationale pharmafst.shop

pharmacie en ligne pas cher pharmacie en ligne sans ordonnance or pharmacies en ligne certifiГ©es

https://www.google.com.ua/url?q=https://pharmafst.com pharmacie en ligne

[url=https://clients1.google.nl/url?q=http://pharmafst.com]pharmacie en ligne fiable[/url] Pharmacie Internationale en ligne and [url=https://17lubbs.com/space-uid-66272.html]pharmacie en ligne[/url] Pharmacie sans ordonnance

pharmacie en ligne pas cher pharmacie en ligne sans ordonnance or pharmacies en ligne certifiГ©es

https://www.google.com.ua/url?q=https://pharmafst.com pharmacie en ligne

[url=https://clients1.google.nl/url?q=http://pharmafst.com]pharmacie en ligne fiable[/url] Pharmacie Internationale en ligne and [url=https://17lubbs.com/space-uid-66272.html]pharmacie en ligne[/url] Pharmacie sans ordonnance

https://kamagraprix.com/# kamagra 100mg prix

https://kamagraprix.com/# kamagra 100mg prix

trouver un mГ©dicament en pharmacie: Meilleure pharmacie en ligne – Achat mГ©dicament en ligne fiable pharmafst.com

trouver un mГ©dicament en pharmacie: Meilleure pharmacie en ligne – Achat mГ©dicament en ligne fiable pharmafst.com

kamagra pas cher Kamagra Commander maintenant or Acheter Kamagra site fiable

http://www.google.ad/url?q=https://kamagraprix.com kamagra 100mg prix

[url=https://www.google.bs/url?sa=t&url=https://kamagraprix.com]Kamagra pharmacie en ligne[/url] acheter kamagra site fiable and [url=http://umsr.fgpzq.online/home.php?mod=space&uid=10355]kamagra oral jelly[/url] Kamagra Commander maintenant

kamagra pas cher Kamagra Commander maintenant or Acheter Kamagra site fiable

http://www.google.ad/url?q=https://kamagraprix.com kamagra 100mg prix

[url=https://www.google.bs/url?sa=t&url=https://kamagraprix.com]Kamagra pharmacie en ligne[/url] acheter kamagra site fiable and [url=http://umsr.fgpzq.online/home.php?mod=space&uid=10355]kamagra oral jelly[/url] Kamagra Commander maintenant

Achat Cialis en ligne fiable Tadalafil 20 mg prix sans ordonnance or Cialis sans ordonnance pas cher

https://clients1.google.com.bn/url?q=http://tadalmed.com Acheter Viagra Cialis sans ordonnance

[url=https://webhosting-wmd.hr/index?URL=https://tadalmed.com]Tadalafil sans ordonnance en ligne[/url] Tadalafil sans ordonnance en ligne and [url=https://forum.panabit.com/home.php?mod=space&uid=420618]cialis prix[/url] Acheter Viagra Cialis sans ordonnance

Achat Cialis en ligne fiable Tadalafil 20 mg prix sans ordonnance or Cialis sans ordonnance pas cher

https://clients1.google.com.bn/url?q=http://tadalmed.com Acheter Viagra Cialis sans ordonnance

[url=https://webhosting-wmd.hr/index?URL=https://tadalmed.com]Tadalafil sans ordonnance en ligne[/url] Tadalafil sans ordonnance en ligne and [url=https://forum.panabit.com/home.php?mod=space&uid=420618]cialis prix[/url] Acheter Viagra Cialis sans ordonnance

olympe: olympe casino cresus – olympe

olympe: olympe casino cresus – olympe

This website offers a large assortment of decorative wall clocks for every room.

You can explore urban and timeless styles to match your living space.

Each piece is carefully selected for its craftsmanship and functionality.

Whether you’re decorating a functional kitchen, there’s always a beautiful clock waiting for you.

best nautical brass wall clocks

Our assortment is regularly renewed with trending items.

We prioritize quality packaging, so your order is always in safe hands.

Start your journey to perfect timing with just a few clicks.

This website offers a large assortment of decorative wall clocks for every room.

You can explore urban and timeless styles to match your living space.

Each piece is carefully selected for its craftsmanship and functionality.

Whether you’re decorating a functional kitchen, there’s always a beautiful clock waiting for you.

best nautical brass wall clocks

Our assortment is regularly renewed with trending items.

We prioritize quality packaging, so your order is always in safe hands.

Start your journey to perfect timing with just a few clicks.

To leave a comment, you need to log in.

Log In