Get Tech Tips

Subscribe to free tech tips.

Where Do I Measure Delta T?

Over time, I’ve seen people use just about every type of temperature-measuring device in just about every location imaginable. From drilling tiny holes into rooftop unit panels to sticking a K-type wire into a piece of flex duct (I don’t remember why), I’ve done it all.

Coming up through the trade, I’ve been TOLD to measure temperature differentials in many different ways. As I’ve used these methods over and over, I’ve learned a few pros, cons, and things to consider about each one.

Across the Equipment

Measuring temperature across the equipment (from plenum to plenum) is by far the most common and popular way to check equipment. This method has its pros and cons. The pros are that it’s easy and tells you how the equipment is performing.

I particularly like this measurement on furnace heat checks because you can compare the heat rise from your temperature readings to the equipment’s rated heat rise.

One thing you need to be aware of is that if you’re checking the temperature differential in cooling mode with an evaporator coil after the furnace, your probes will be affected by the radiant temperature of the evaporator coil. I use the Fieldpiece wireless probes and bend them so the tips face away from the coil. You only want to measure the air temperature change, not inadvertently measure the temperature of the evaporator coil.

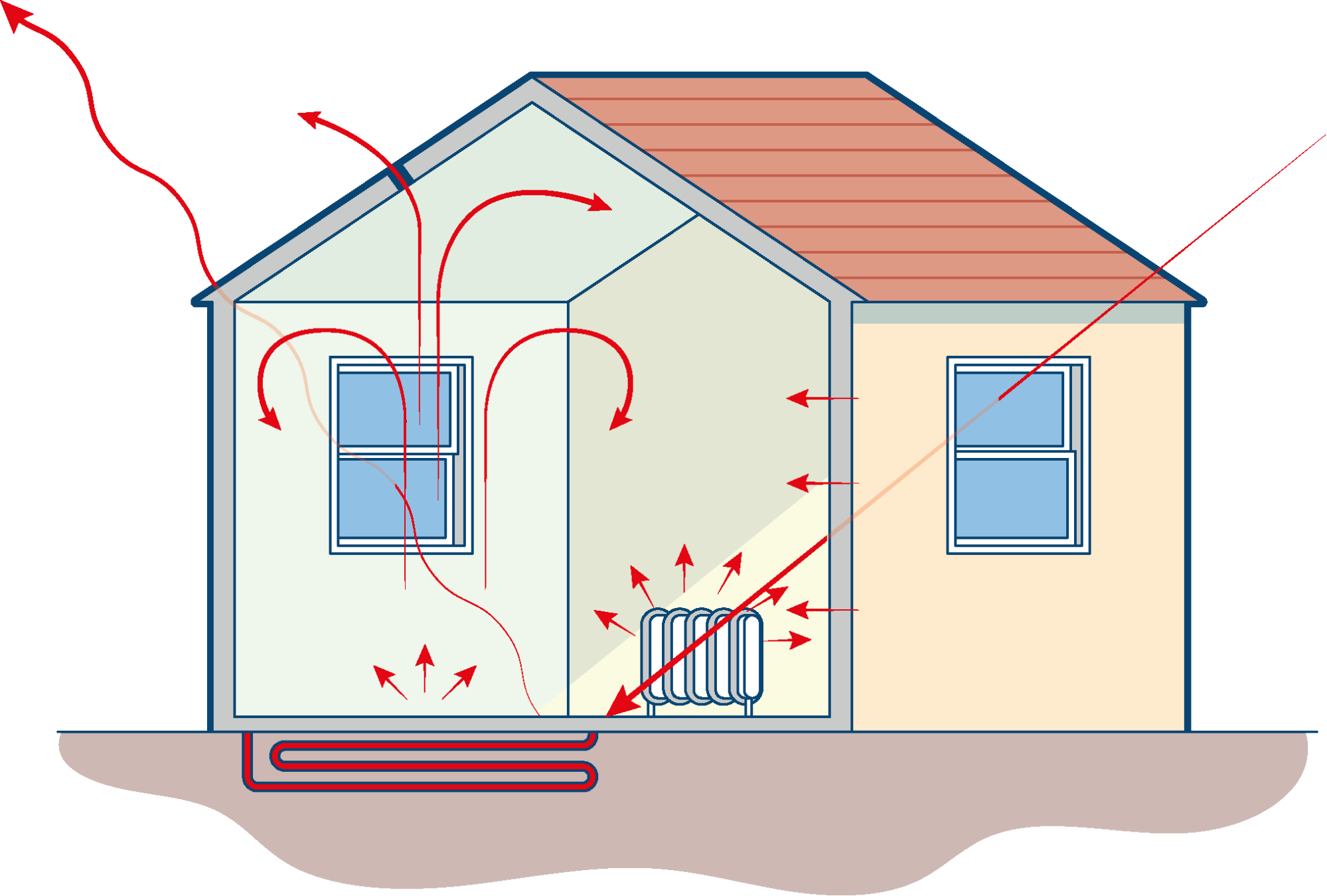

The downside of measuring temperature this way is that typically the HVAC equipment is not sitting in the middle of the room, just dumping air into the space with no ductwork (where my mini splits at??). Knowing how the equipment is operating is great, but it’s hooked up to an air delivery system, and we need to know how that is performing as well.

Across the Ductwork

This method of taking temperature readings gives you an accurate picture of how the system actually delivers all that wonderful cooling it is doing up in the attic. That is what we call “delivered capacity,” meaning what the clients (and thermostat!) actually experience in the living space.

This method can help you find duct leakage, as well as duct gains and losses on extremely hot or cold days, and solve comfort complaints. You may not see much of a difference between checking across the equipment and across the ductwork on mild days. However, extreme outdoor temperatures can change that.

Combining the Two

A few summers ago, I was at a house where the homeowner was complaining that one wing of the house wasn’t cooling well. It was the furthest room from the HVAC equipment, and the ductwork was… not great. It was a hot day out, and the system used the wall cavities as the return side of the duct system.

I measured the return temperature at the vent in the living space, and it was around 75 degrees. However, up in the attic at the filter rack, the return air temperature was around 90 or 95 degrees. The system was cooling as efficiently as it could (I had a 15-20 degree differential at the equipment), but the supply air temperature was just about the same as the return air temperature at the grille in the living space.

So, what would have actually solved the problem? Replacing or upsizing the duct to the far room (which was my first assumption as to what the problem was) or moving the returns to the ceiling and eliminating the leaky wall cavities as returns?

I have seen this problem again and again on hot days. MeasureQuick is great in this scenario, as you can see the delivered capacity in the attic across the equipment and then compare that to what the duct system is actually delivering. MeasureQuick actually has an even more advanced test that can calculate return air duct leakage.

In another instance, I measured supply air temperature in an individual duct run and then at the register, and the duct lost all of its cooling due to heat gain through the attic. In fact, someone tried to solve this by making that duct a “home run,” but using a 5-inch duct. The problem was not the AMOUNT of air delivered but simply the heat gain into the ductwork running across a hot attic.

Takeaways

- If you’re going to take your temperature differential across the equipment, make sure to keep your temperature probe out of the line of sight from the heating/cooling coil, as it will make things look better (or worse) than they really are.

- Don’t use an infrared thermometer. Here’s why.

- Get something that can measure enthalpy/humidity, not just temperature. Then, you can check sensible AND latent capacity.

- Checking the temperature differential across the ductwork will give you a more accurate picture of how the system is performing, not just the equipment.

- Using both together can give you some great data for troubleshooting.

I hope that helps!

Comments

This is really good info. After reading this article, I realize that I not only need to be taking measurements at the ductwork but at other points where there could be duct losses/gains. Especially in the attic. I will do better in the future.

Thanks for the info Brian!

This is really good info. After reading this article, I realize that I not only need to be taking measurements at the ductwork but at other points where there could be duct losses/gains. Especially in the attic. I will do better in the future.

Thanks for the info Brian!

To leave a comment, you need to log in.

Log In