Get Tech Tips

Subscribe to free tech tips.

The Wide-Narrow-Wide of Manual J

Starting to work on a Manual J load calculation can feel extremely overwhelming. How do we know what to focus on? What does normal look like? What if I’m way off on something and install way too big or small of a unit? On a practical level, what is the payback or value of spending a lot of time figuring out what is inside the wall cavities of a home? How much will the load change if I can’t find the exact data I need for the windows and all I can confirm is that they are double pane? Or, the most controversial topic of recent years, how much does infiltration affect load?

Russ King, a mechanical engineer with years of field experience and the creator of Kwik Model—a 3-D load calculation software—is fond of saying:

“Don’t get caught up splitting hairs when we should be shaving heads.”

He’s saying we ought to focus on what really matters within the load calculation. If you know the house has insulation in the walls, the difference between R11 and R15 in the cavity isn’t going to change the load much. Move on to something else. To focus on the things that really matter, we need to have a general understanding of what a load calculation is, how different factors affect the load, and how to spot potential red flags.

We call this the wide-narrow-wide of Manual J. This approach calls for a 50,000-foot view of what we are doing, digging into the details and spending our time where it will give us the biggest payback, and then zooming back out to make sure the pieces all fit back together.

This is the first article in a series on how to perform a Manual J load calculation on an existing home. The following articles will dig specifically into each building material category.

What Matters?

Again, the idea here is to provide you with a decent understanding of where to spend your time and energy. Having an idea of where big shifts in the load can come from will help you decide whether you need to dig deeper or recommend building upgrades before installing a new system. There may be times when upgrading the home can lead to significant equipment downsizing and could be worth considering.

Below is a list of the different building components needed for a Manual J load calculation. This list includes the big-picture questions that will affect how large of a portion of the load each component could potentially be. It will take a while to feel confident with your data, but you will start to get a “feel” for what normal looks like as you do more load calculations. Odd numbers or percentages will start to stick out to you. Reach out to a trusted mentor, post your questions in the HVAC School Facebook group, or email us if you have any concerns.

Windows

Do you have a roof overhang that provides shade for the windows? Do you have a lot of east/west-facing windows? Are there any rooms with a significant amount of glass, like a conditioned sunroom? West-facing windows will cause the highest increase in load on a hot summer afternoon because the sun is shining in during the hottest part of the day.

Walls and Ceilings

The biggest factor with walls and ceilings is to determine whether they have a lot of insulation, some, or none at all. Beyond that, variations in insulation will likely have very little impact on the load. An R13 vs. an R11 wall will likely not change the load much.

Floors

Slab floors absorb heat year-round due to soil temperatures remaining fairly constant. A slab-on-grade floor is a big heat sink. It has no impact on the cooling load in the summer, but in the winter, it absorbs the heat you want to keep in your house.

Vented crawlspaces add load in the summer and winter because outside air flows freely through them. These types of floors substantially increase the load on a house and drive increased infiltration. Encapsulating a crawlspace can make a huge impact on the comfort and indoor air quality of a home, but it's an expensive fix.

Anytime you see a room over a garage, flag it in your mind as a potential problem. If the floor of the room is not insulated and air-sealed, it can be very uncomfortable and hard to condition. For more on this topic, check out this podcast episode with design guru Alex Meaney.

Basements act very similarly to crawlspaces in terms of heat gains and losses but are more likely to be conditioned.

Infiltration

Infiltration might be one of the most overlooked data entry points in a load calculation but also one of the most important. A loose vs. a tight house is like the difference between wearing a loose knitted sweater vs. a windbreaker on a cool windy day. If the air makes it through the home through gaps and cracks, you better believe that will have an impact on your load calculation.

If you have the resources, the most accurate way of modeling infiltration is to measure it using a blower door. Manual J software allows you to enter your blower door number (CFM 50), or you can take a guess. But what happens when you guess wrong? The answer is that it depends. How wrong are we talking? If the guess is pretty far off, it can drastically swing your load calculation, causing you to inadvertently oversize or undersize the equipment. Choosing “average” infiltration may be the safest bet. If you choose average, you are right in the middle of the infiltration spectrum. Therefore, if the house is either really loose or extremely tight, you are only half as wrong as you otherwise potentially could have been. For a deeper dive into the topic, Genry Garcia wrote an excellent article digging into the weeds of infiltration on a problem house.

Interior Loads

Are there any abnormal interior loads in the house, like a giant fish tank or cryptocurrency mining operation? A mom with ten kids doing laundry all the time? These variables could affect the latent or sensible load.

Ducts

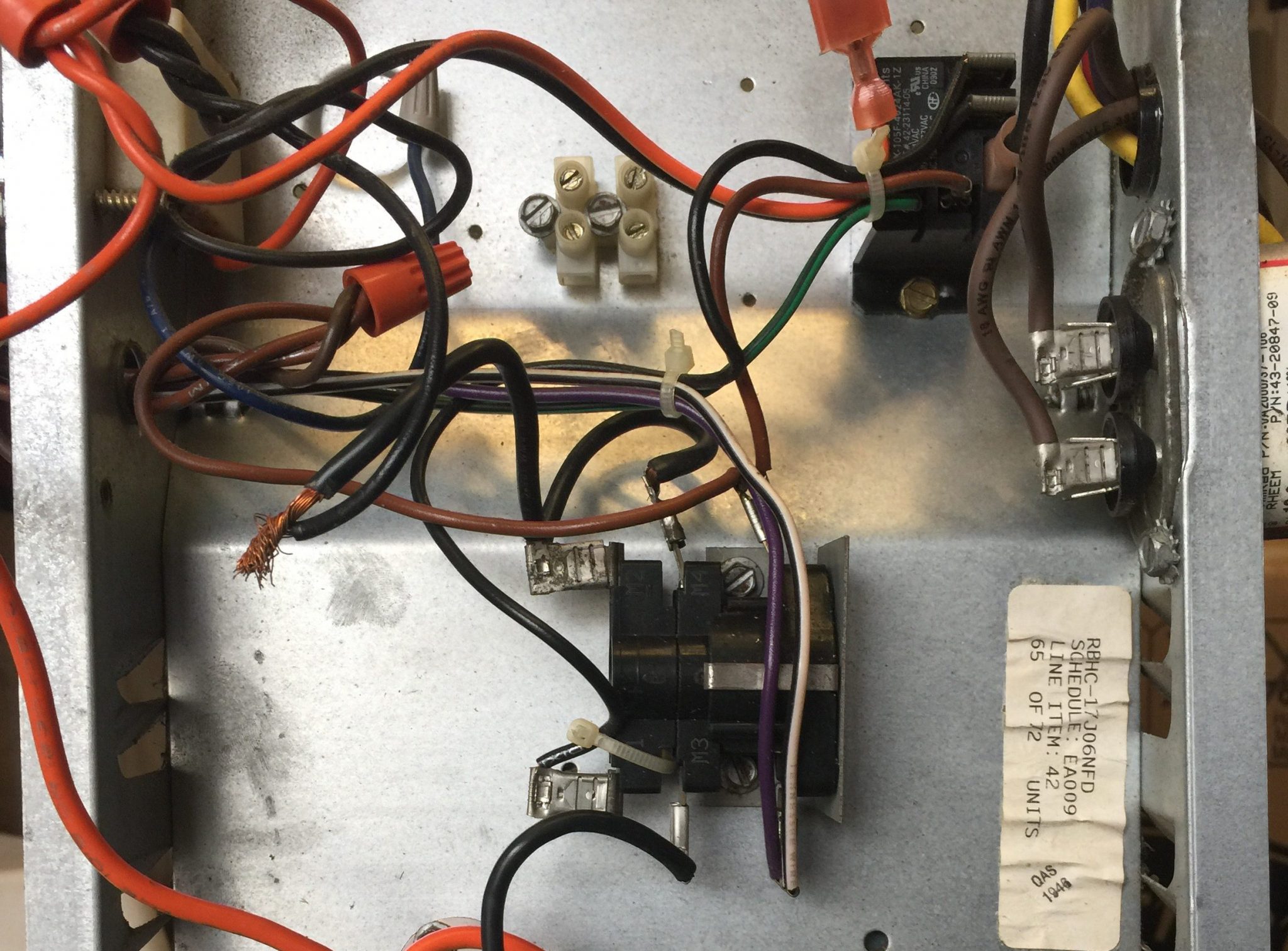

Is the duct system in a conditioned or unconditioned space? Is it air-sealed? Where are the returns located? A leaky duct system can add a LOT of load to the house and increase infiltration, which can add even MORE load to the house. Check out this podcast episode with Steve Rogers from TEC for a deeper dive. A quick visual inspection can tell you if the system is air-sealed at all, and an unsealed metal duct system can have a much higher impact on the load than flex because there are many more unsealed seams and connection points.

Duct leakage outside of the envelope, otherwise known as duct leakage to the outside, can cause “HVAC-induced infiltration.” A return duct will draw in unconditioned air from outside, which adds to the load of the home. It will also pressurize the home, which increases exfiltration or air leaking out of the home.

Steven Rogers from The Energy Conservatory frequently refers to supply duct leakage to outside as a “double whammy.” The reason is that it has a larger impact than return duct leakage alone. If you leak supply air to the outside, you are reducing the system’s delivered capacity, paying for conditioned air that never had a chance to heat or cool the home. The other “whammy” is that you are taking air from the home and moving it outside. This condition causes the home to become depressurized, which in turn will increase the home's infiltration. The HVAC system is causing more unconditioned air to leak into the home, increasing the load.

The problem is that most people would assume installing larger equipment would overcome the effects. The reality is that larger equipment requires more airflow, and more airflow will increase the duct leakage, which only makes the underlying problem worse.

Regionality

Different parts of the country will have different opportunities for upgrades and low-hanging fruit. There are several neighborhoods where I live that have wall cavities used for return ducts. These are extremely leaky, causing high return air temperatures due to duct leakage to the outside and derating the equipment when capacity is needed most. I’ve tested several of these systems during the middle of the summer and seen the extra strain it causes on systems. When I quote a system replacement on a home in these neighborhoods now, I highly recommend moving the returns from the walls to the ceiling.

As you get to know your region, you will begin to identify the most valuable upgrades for your clients and can recommend them with more confidence.

Zooming Back Out

Once you’ve collected your data and have a broad understanding of where issues in the load may come from, enter all of your data into your software of choice. Once you have a working load calculation, step back and take a look at all the pieces of the pie. Do they make sense? Did you notice anything during your field observations that is at odds with the report?

Remember, getting good at this will take time. Your first load calculation will likely not be your best, just like your first system installation was not your best. The goal here is not perfection but progress. The idea that we have to do a perfect load calculation or just throw up our hands and size by 500 square feet per ton is not helpful. All of our work is a creative training ground. Getting some reps in by doing a couple of load calculations will open your eyes and make you hungry to keep learning and growing. Do the best you can, but don’t become paralyzed by not being able to do it perfectly.

—Matt Bruner

Comments

Bonus Room Tip. They are rooms built above a living are below it. The have floor trusses for the floor. Be sure to find out where the floor insulation is, it should be in contact with the Bonus Room Floor, not the ceiling of the living area below, which we have found it to be in many homes. This lets hot air from the adjacent attic to circulate under the floor, adds a lot to the heat gain of the Bonus Room. If you have a Bonus Room that is too warm in cooling mode, check the floor temperature with a laser thermometer! If you seal off the perimeter of the floor trusses from the attic area with insulation, it doesn't matter where the insulation is in the floor trusses, prevents the hot attic air from getting in there.

Bonus Room Tip. They are rooms built above a living are below it. The have floor trusses for the floor. Be sure to find out where the floor insulation is, it should be in contact with the Bonus Room Floor, not the ceiling of the living area below, which we have found it to be in many homes. This lets hot air from the adjacent attic to circulate under the floor, adds a lot to the heat gain of the Bonus Room. If you have a Bonus Room that is too warm in cooling mode, check the floor temperature with a laser thermometer! If you seal off the perimeter of the floor trusses from the attic area with insulation, it doesn't matter where the insulation is in the floor trusses, prevents the hot attic air from getting in there.

Excellent point! That’s a great tip

Excellent point! That’s a great tip

To leave a comment, you need to log in.

Log In