Get Tech Tips

Subscribe to free tech tips.

Maintenance During Major Repairs

Every contractor is different. I get that.

We don't all need to do everything the same way or include the same services with repairs, but there are some “best practices” that can save you a lot of heartache before, during, and after you make a big repair.

Catch it During Diagnosis

Let's say you find a failed, shorted compressor on a 7-year-old system that still has manufacturer parts coverage. If you simply quote the compressor and leave, you may be missing many other maintenance-related issues that can affect operation once the compressor is replaced. A shortlist of items to check would be:

- Look at the accumulator for signs of corrosion.

- Perform an acid test to see if a burnout protocol should be employed. (Read more about burnouts HERE.)

- Check the air filter.

- Inspect the condenser coil's cleanliness.

- Look at the underside of the evaporator coil.

- Perform a static pressure test on the system to check for duct issues. (Read more about static pressure HERE.)

- Check the crankcase heater (if it has one). (Read more about crankcase heaters HERE.)

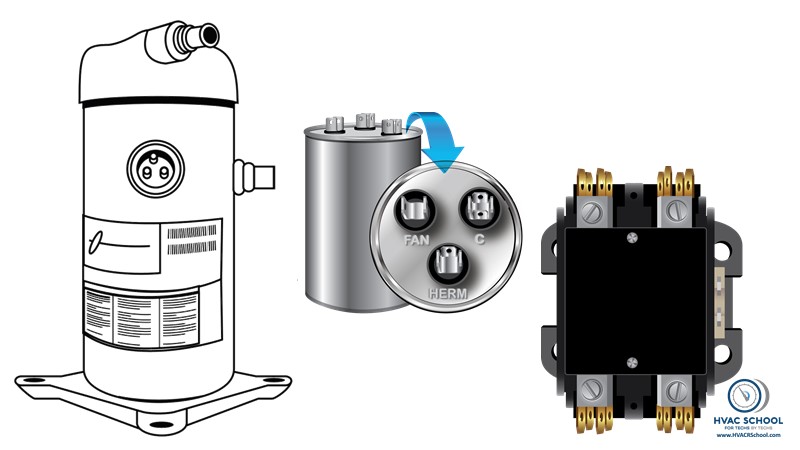

- Inspect the contactor.

- Check condenser fan and blower motor amps.

- Test all capacitors. (Here's an easy way to test capacitors.)

- Visually inspect wires and cap tubes.

- Check high-voltage electrical connections.

And this is just for cooling side issues. If the system is a fuel-burning appliance, you will inspect every part of the furnace operation.

- Venting

- Condensate drainage

- Burners

- Flame proving

- Safeties

And much more…

Testing all of these things is commonplace AFTER a repair. Still, it makes so much more sense to do it beforehand so that you can either charge appropriately for any of these items that need to be addressed or let the customer know you are including those items to differentiate you from the competition.

Things to Do Along With Major Repairs

There are a few things you need to do during major air conditioning or refrigeration repairs because they just make good sense to prevent callbacks. You can include them in the price or not, but either way, it will save you more than it costs to do it.

- Visually inspect the entire system for wiring damage, poor connections, excessive corrosion and refrigerant oil

- Clean the drain line and condensate pan. (Seriously, do this. Here's a guide.)

- Wash the condenser coil

- Clean the blower wheel if it is dirty. (Even if you've heard otherwise, you should still clean it if it's dirty.)

- Change the air filter

- Test all modes of operation

- Ensure system airflow is correct (at minimum look at blower settings and static pressure)

- Measure compressor and evaporator superheat

- Measure subcooling and ensure a proper refigerant charge

Do these things along with all the standard tests you perform to ensure that you have no issues and that whatever caused the fault in the system has been rectified. Being thorough will save you a lot of problems. When the customer spends a lot of money getting a system fixed, they don't want to turn around and have it fail for an “unrelated” reason.

While this list is clearly tailored to the residential and light commercial air conditioning market, every piece of equipment has its common maintenance items. So, what do you do whenever you make a major repair?

—Bryan

Comments

Good list but should be done on every call not just major repairs.

Gas furnace

•Check/clean drain lines & trap

•Inspect intake/exhaust for proper slope & termination, blockage

•Clean flame sensor

•Ohm out ignitor

•Check/clean blower, filter, evap coil, & if suspected to possibly be dirty secondary heat exchanger

•Temperature rise & if needed manifold pressure & duct static pressure

•Inspect heat exchanger

•Teat high limit

Good list but should be done on every call not just major repairs.

Gas furnace

•Check/clean drain lines & trap

•Inspect intake/exhaust for proper slope & termination, blockage

•Clean flame sensor

•Ohm out ignitor

•Check/clean blower, filter, evap coil, & if suspected to possibly be dirty secondary heat exchanger

•Temperature rise & if needed manifold pressure & duct static pressure

•Inspect heat exchanger

•Teat high limit

mail order prescription drugs from canada

mail order prescription drugs from canada

pharmacy cost comparison

pharmacy cost comparison

best price prescription drugs

best price prescription drugs

pharmacy world

pharmacy world

online prescriptions without a doctor

online prescriptions without a doctor

buying prescription drugs canada

buying prescription drugs canada

cost prescription drugs

cost prescription drugs

prescription drug assistance

prescription drug assistance

pharmacie en ligne: Pharmacies en ligne certifiees – acheter mГ©dicament en ligne sans ordonnance pharmafst.com

pharmacie en ligne: Pharmacies en ligne certifiees – acheter mГ©dicament en ligne sans ordonnance pharmafst.com

Kamagra pharmacie en ligne Achetez vos kamagra medicaments or kamagra livraison 24h

https://toolbarqueries.google.mw/url?q=http://kamagraprix.com Acheter Kamagra site fiable

[url=https://www.google.com.uy/url?q=https://kamagraprix.com]kamagra en ligne[/url] Achetez vos kamagra medicaments and [url=https://17lubbs.com/space-uid-66617.html]kamagra 100mg prix[/url] kamagra pas cher

Kamagra pharmacie en ligne Achetez vos kamagra medicaments or kamagra livraison 24h

https://toolbarqueries.google.mw/url?q=http://kamagraprix.com Acheter Kamagra site fiable

[url=https://www.google.com.uy/url?q=https://kamagraprix.com]kamagra en ligne[/url] Achetez vos kamagra medicaments and [url=https://17lubbs.com/space-uid-66617.html]kamagra 100mg prix[/url] kamagra pas cher

https://kamagraprix.com/# Kamagra Commander maintenant

https://kamagraprix.com/# Kamagra Commander maintenant

pharmacie en ligne avec ordonnance: pharmacie en ligne sans ordonnance – pharmacie en ligne fiable pharmafst.com

pharmacie en ligne avec ordonnance: pharmacie en ligne sans ordonnance – pharmacie en ligne fiable pharmafst.com

https://kamagraprix.com/# kamagra 100mg prix

https://kamagraprix.com/# kamagra 100mg prix

casino olympe: casino olympe – casino olympe

casino olympe: casino olympe – casino olympe

Great point. In your example if we do a compressor, we have codes in our system that tells to replace the : Dryer, contactor and capacitor. even if they are in good shape. A compressor is too expensive to have it fasil in a week or a month. $40 in extra parts ensures you will have a compressor that stays working.

Great point. In your example if we do a compressor, we have codes in our system that tells to replace the : Dryer, contactor and capacitor. even if they are in good shape. A compressor is too expensive to have it fasil in a week or a month. $40 in extra parts ensures you will have a compressor that stays working.

Treat your service calls like tune ups and treat your tune ups like service calls

Treat your service calls like tune ups and treat your tune ups like service calls

Thanks for the reminder that overheating is actually one of the common problems that air conditioners have at some point. I plan to get air conditioning repairs for that soon. It seems that mine has been guzzling a lot more electricity nowadays.

https://www.winstonsheetmetalandhvac.com/

Thanks for the reminder that overheating is actually one of the common problems that air conditioners have at some point. I plan to get air conditioning repairs for that soon. It seems that mine has been guzzling a lot more electricity nowadays.

https://www.winstonsheetmetalandhvac.com/

Kamagra Oral Jelly pas cher [url=https://kamagraprix.com/#]Kamagra pharmacie en ligne[/url] kamagra en ligne

Kamagra Oral Jelly pas cher [url=https://kamagraprix.com/#]Kamagra pharmacie en ligne[/url] kamagra en ligne

To leave a comment, you need to log in.

Log In