Get Tech Tips

Subscribe to free tech tips.

Checking the Charge Without Gauges (Our Process)

This is an internal guide we use at Kalos, and it works for our climate and the type of HVAC equipment we work on. Consult with your company leadership before implementing this or any process. Keep in mind that some of these guidelines are “made up” by me and are only useful in the absence of manufacturers' data. The non-invasive test mode in the MeasureQuick app is a better method for testing many of these parameters.

Fieldpiece JobLink Rapid Rail Temperature Clamp

Checking The System (and Charge) Without Gauges

First, checking the charge without gauges is a balancing act, a trade-off. We get more accurate readings when we connect gauges, but we also:

- Lose some refrigerant

- Risk contaminating the system with moisture and air

- Risk leaving a leak at the Schrader cores and caps

Like everything, your best INITIAL diagnosis tools are your hands, eyes, and ears. Look for dirt buildup, spot oil, listen for abnormal sounds, feel the lines and condenser discharge air when approaching the condenser, check for dirty blower wheels, evaporators, filters, and grilles when approaching the indoor unit. Look for wire and refrigerant tube rub-outs, look inside drain cleanout tees and in pans for gunk and buildup, look inside condensers for wires laying on the tubing, pay attention to disconnects that are loose, belts and sheaves that are worn, high-voltage connections that are getting discolored, capacitors that are bulging or leaking, electrical whips that are coming apart, stat wires that are nicked or bare, air handlers that are sagging or out of level, ducts full of mildew and broken, or damaged line insulation. In refrigeration, look for icicles hanging down, torn insulation on drains and suction lines, dirty EVERYTHING, and damaged doors and door seals.

THERE IS NO TEST PROCEDURE THAT REPLACES AN AWARE TECHNICIAN. NOTICE EVERYTHING, QUOTE TO REPAIR EVERYTHING. BE PROACTIVE, WALK THE SITE, FIX PROBLEMS BEFORE THEY OCCUR. LOOK BEYOND THE FIRST PROBLEM AND EVEN THE FIRST SYSTEM. CONSIDER THE SPACE VENTILATION, INSULATION, AND OCCUPANTS. READ MANUFACTURER DATA TAGS, LOOK AT THE BACKS OF PANELS, AND READ MANUFACTURER INSTALLATION AND SERVICE DATA WHENEVER POSSIBLE.

This means that we only connect gauges when there is a good reason to do so, such as:

- We have not touched the unit recently and want to make sure it is operating 100% (on air conditioning only; in small refrigeration, you still don’t connect in this case).

- We made a significant repair that may impact the operation.

- We need to “set” a charge because the system is newly started, or we made a refrigerant circuit repair.

- Your readings or your gut tell you that you are out of range or a problem may exist.

On a system that has been appropriately commissioned, you will have prior readings to go off of. Keep in mind that some benchmarks like DTD (evaporator to return air design temperature difference), CTOA (condensing temperature over ambient), subcool and superheat on a TXV system, and static pressures.

Readings like suction pressure, head pressure, superheat, and subcooling on a fixed metering device system and air temperature split will vary with load conditions. If you have historical system data, you can often use it to learn about the system and its history before you begin taking readings.

When checking an air conditioning system without gauges, do it in the following steps (these are subject to change and adjustment based on historical benchmarks, abnormal conditions, and manufacturer specs):

- Visually inspect the unit for all the above-listed items AND note if the metering device is a piston or a TXV.

- Measure the outdoor temperature in the shade entering the condenser. This procedure will work best during outdoor temperatures of 70°F – 95°F.

- ADD the CTOA (condensing temperature over ambient) based on the SEER rating and/or age.

- Subtract the nameplate subcooling or 10° if there is no nameplate.

- Compare to the liquid line temperature. If +/- 3° on a TXV system or +/- 5° on a piston, the liquid temperature is in range.

- You may also check the air temperature leaving the condenser fan, and it will usually be about ½ of the target CTOA (condensing temperature over ambient). So, on an ancient system with a CTOA of 30°F, the condenser discharge air will generally be 15°F +/- 3°F, and on a brand new high SEER unit with a CTOA of 15°F, it will be 7.5°F +/- 3°F.

- Also, note how much warmer the liquid line is than the outdoor temperature. It should be between 4° and 18° warmer than the outdoor temperature. If it is above or below that range, connect gauges.

- Measure the suction line temperature outside. If it is at or above 65°, the compressor is in danger of overheating / oil breakdown. If the suction line is 40° or below, the unit is at risk of freezing. Stop and connect gauges.

- Go inside and check the wet bulb and dry bulb temperature at the air handler/furnace inlet (return right before the inside unit or in the filter tray/cabinet; make sure to keep the sensor out of “line of sight” from the evap coil). The indoor temperature should be between 70°DB and 80°DB for the best use of this method.

- Take the return dry bulb (DB) and subtract 35°F (DTD); this is your target coil temperature difference.

- If the system has a TXV, add in 10° for superheat; if it is a fixed orifice (piston), then add in the target superheat based on a superheat chart or using the HVAC School app. This gives you a target suction line temperature at the evaporator.

- Compare the target suction line temperature to the actual suction line temperature at the evaporator; if it is within +/- 5°F, it is within range. If it's outside of that range, connect gauges.

- Compare the indoor suction temp to the outdoor suction temp. 1°F of change per 20’ of line set is allowable.

- Compare the indoor liquid line temp to the outdoor liquid line temp. 1°F change per 30’ of line set is allowable.

- Check temp drop across all exposed line filter driers. Recommend replacement if there is a drop of 3°F or more across a filter drier and perform further testing if you get even 1°F of reduction with the same, accurate thermistor clamp.

- Use a delta T chart (like this one) to calculate the target evaporator air temperature split; if the split is within +/- 3°F, it is within range. If it's higher, then check for airflow issues and blower settings. If it's lower, then connect gauges.

- When checking an RTU (rooftop unit) or residential package unit, you will often have easy access to the compressor. In those cases, check the suction temp entering the compressor and the discharge temp leaving the compressor. The suction temperature should be above 35°F and below 65°F entering the compressor (depending on indoor conditions), and the discharge line temperature should be below 220°F and above 150°F on a properly functioning RTU during typical indoor and outdoor conditions. NOTE: On an RTU, make sure you are not attempting to measure liquid line temperature/CTOA rules when connecting to the DISCHARGE line. Also, make sure that panels are in place for the condenser, blower, and evaporator sections when run testing. When there is something that looks like a liquid line drier but is in the discharge line, it is a muffler, not a filter/drier.

- Check amps against manufacturer rating plates or part data plates if the compressor, blower, or condensing fan motor is aftermarket.

- Check capacitors, preferably while running.

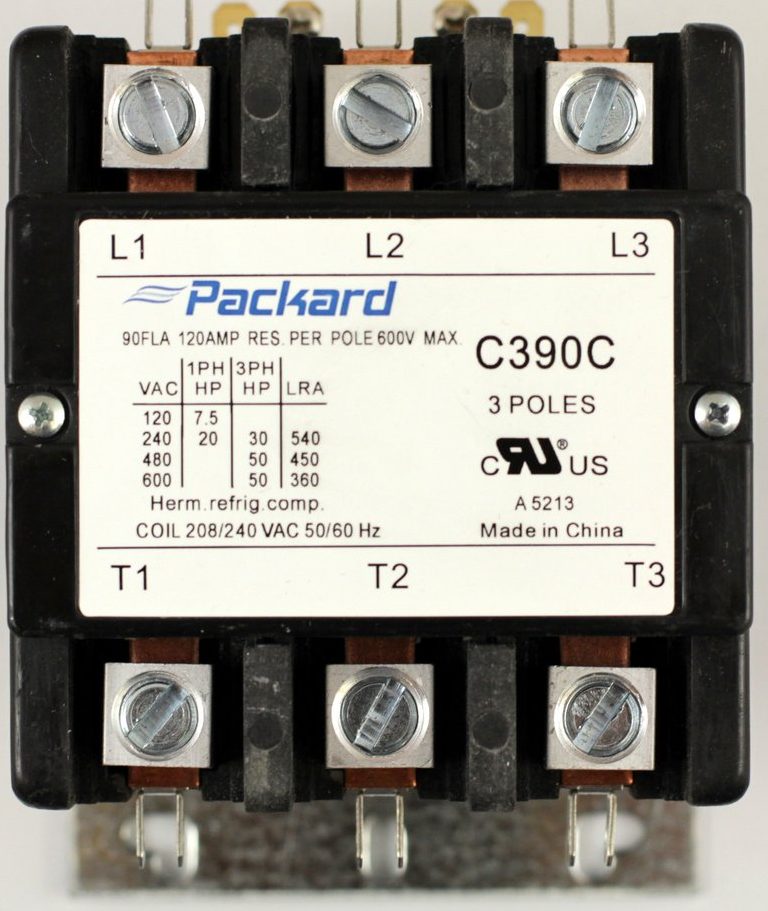

- Check the incoming voltage to the contactor and ensure it is within 5% of the rated voltage. In general, this means ensuring that voltage is over 198V from leg to leg on a 208V System and over 228V on a 240V system. This is based on the NEC 215-2(d) suggested guideline, not manufacturer specs, so it isn’t set in stone.

- Confirm that the voltage imbalance on a three-phase system does not exceed 2%.

- When applicable, check TESP and static pressure drop across coil and filters against benchmarks.

- Confirm drainage and test/inspect float protection devices.

BEWARE of these common readings mistakes:

- Reading air temperatures in sunlight. If the sun is shining on a probe, it will always read too high.

- Reading air temperature in a place that is “line of sight” to a cold or hot surface like a coil, heat strips, heat exchanger, etc. It is always best to have a probe in an area shielded from other hot or cold surfaces.

- Reading line temps in an uneven or dirty area of the tubing. The sensor on your temp clamp must have full, flat, clean, tight contact to the line being measured.

- Trusting tools without testing tools. All tools require proper care and maintenance and must and can be tested. They can be tested against other tools or a known constant (like the freezing temp of water), or they can be calibrated by a lab. Know your tools and learn how to test them.

- Taking pressure readings without a fully depressed Schrader core. When checking refrigerant pressures or measuring vacuum with a micron gauge, the cores must be fully depressed (pushed in). If your hoses or couplers are not FULLY depressing the cores, you will see odd readings. When in doubt, replace the Schrader with a core tool and try another hose.

This process is not a theory or diagnosis guideline; it is simply a practical process for verifying PROPER operation for a range of common air conditioning equipment. If you find readings outside of the guidelines listed, you will need to connect gauges and further diagnose the system. Before using this guideline, it is highly recommended that you read and understand the following training modules:

Common refrigerant Circuit Terms

The 5 Pillars of Refrigerant System Diagnosis

Checking a Charge W/O Gauges Article by Jim Bergmann

Checking a Charge W/O Gauges Parts one and two

Charging an Air Conditioner by TruTech Tools

Comments

To leave a comment, you need to log in.

Log In