Get Tech Tips

Subscribe to free tech tips.

Why is 3/8″ Liquid Line So Common? – Liquid Line Sizing

You may have noticed that 3/8″ liquid lines are generally the norm in equipment 5 tons and under. We went to a job where the system had a 1/2″ liquid line, and it got me thinking about the ramifications of going larger or smaller on the liquid line.

Liquid Line Basics

The liquid line should be full of liquid with additional subcooling to prevent flashing due to pressure drop from the length, rise, fittings, and filter/drier. Because liquid refrigerant is much denser than vapor, the liquid line contains a relatively large amount of refrigerant compared to the much larger vapor line.

Even small changes in liquid line size can significantly impact refrigerant velocity in the liquid line and the amount of charge contained in it. That is why we see a big variation in suction line size but very little change in liquid line size in residential applications.

Pressure drop in the liquid line is only a concern when it results in flash gas or an unacceptably low pressure drop across the metering device. Flashing occurs when the refrigerant pressure drops to the point that all of the design subcooling is “used up,” and the refrigerant in the liquid line begins to boil off. Up until that point, the pressure drop will result in a negligible temperature drop.

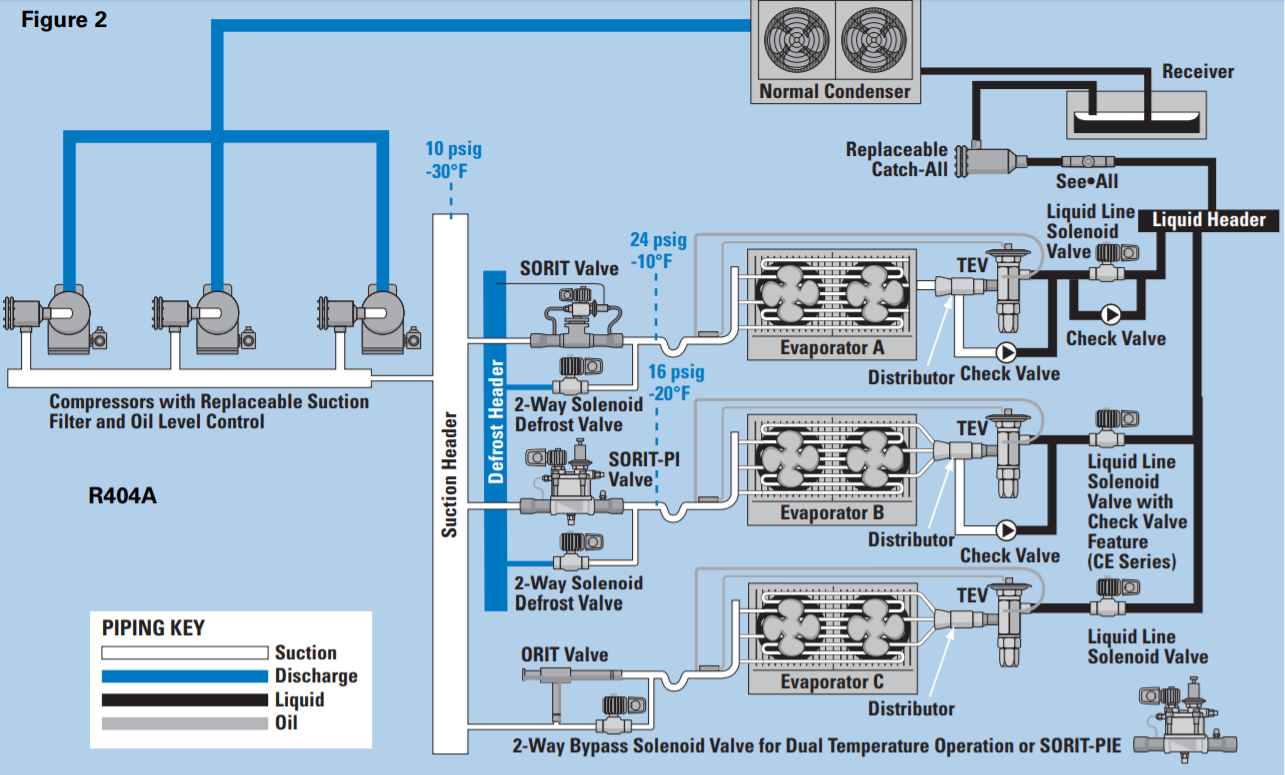

From the Lennox Design and Fabrication Guide

Liquid Line Sizing Factors

We need to size the liquid line with the following factors in mind:

- Keep the velocity low enough to prevent noise.

- Minimize pressure drop to prevent flashing.

- Refrain from oversizing the liquid line to prevent excess refrigerant charge.

At first, it may seem like bigger would be better on the liquid line, but that isn't the case. An oversized liquid line can lead to a lot more refrigerant charge, which will result in a greater likelihood of off-cycle refrigerant migration and flooded starts—in addition to the cost associated with more charge for no good reason.

From the York/Johnson Piping Application Data Sheet

Our goal should be to use the smallest liquid line size that will still reliably provide a full line of liquid to the metering device under all load conditions that the system will reasonably operate under. Luckily, we don't need to guess; the manufacturers provide us with guidelines for liquid line sizing.

Carrier Liquid Line Sizing Chart

Vertical Pressure Drop/Gain

In general, on an R410a system, we don't want more than about a 35-PSI pressure drop in the liquid line. Otherwise, we run the risk of flashing. When the condenser is LOWER than the evaporator, the liquid line pressure loss is about 0.5 PSI per foot of vertical rise, limiting the rise to around 60′ for R410a systems by the time you consider the other pressure drops.

If the condenser is ABOVE the evaporator, then the pressure actually increases with longer vertical separation, allowing the liquid line to be downsized in some cases.

Each manufacturer has its own piping guide or details in the install instructions or the product data. In most cases, a 3/8″ liquid line is a safe bet, but just like the suction line, there is some wiggle room depending on the system and the specific application.

Here are some great guides:

—Bryan

Comments

To leave a comment, you need to log in.

Log In