Get Tech Tips

Subscribe to free tech tips.

Why Discharge Line Temperature is a Useful Reading

I’d like to give special thanks to Roman Baugh for the section about compressor superheat. It’s not something we talk about very often outside of chiller and commercial refrigeration applications, but it definitely has value in the HVAC world as well. Thanks, Roman!

Since I started in the trade, we would take discharge line temperature in the winter on a heat pump system. You can easily check the discharge line in the winter, while suction superheat and even subcool can be more difficult to access.

The old-timers who trained me would say that the discharge temp will be “about 100 degrees over outdoor ambient” when a properly functioning heat pump system is running in heat mode. That rule of thumb is actually pretty close, but it isn't exact—and what happens if you get a different reading?

First off, if your discharge temperature (as measured with a thermometer at the compressor) is over 225°F, you have an issue. At that temperature on the discharge line, you will have an internal compressor temperature of over 300°F, and the oil will begin breaking down, so even if you check for no other reason, check to make sure you are under 225°F.

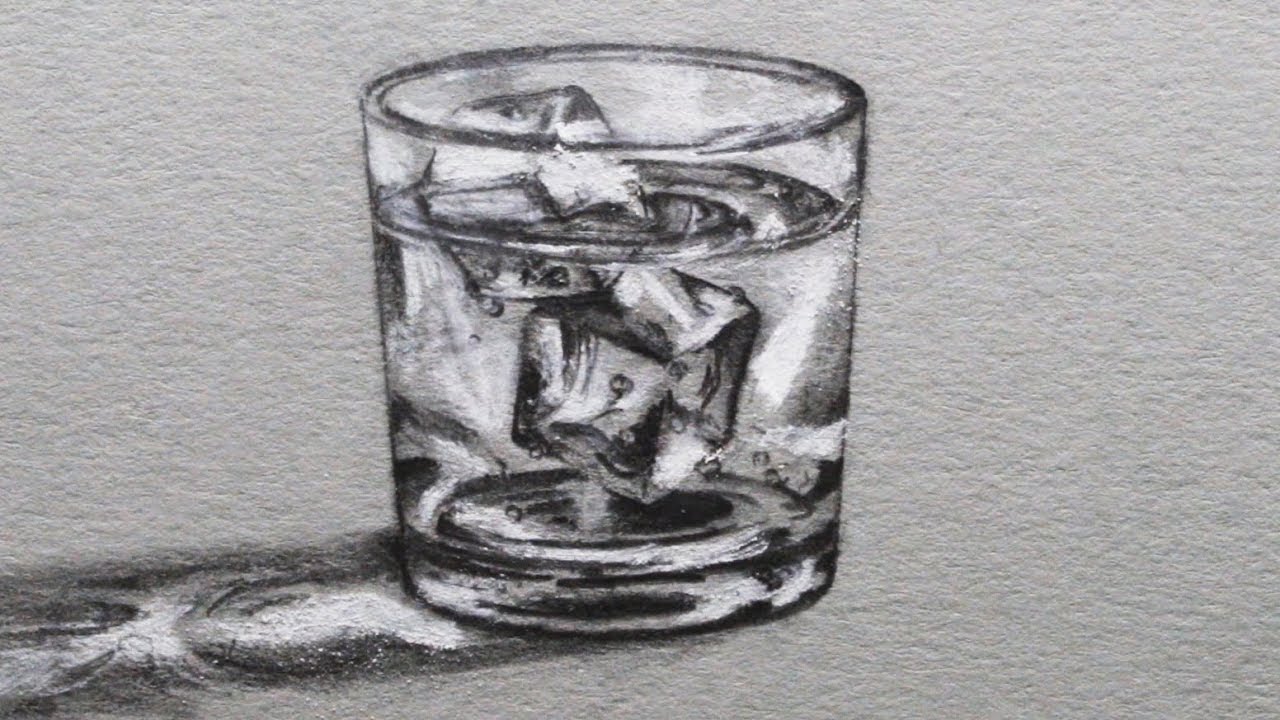

As an aside, PVE oil, which is common in VRF/VRV and ductless equipment, starts to break down at 247°F. That’s well below that 300°F temperature with the “225 stay alive” rule. Once the carbon in the oil has started to break down, the oil loses the properties that help it lubricate the compressor effectively. The picture below shows what that carbonization looks like.

For what it's worth, when I check A/C systems, I commonly see discharge line temperatures between 160 to 180 degrees on properly functioning systems in typical summer conditions in Florida.

Compression Ratio

A high head or low suction pressure can cause a higher discharge line temp. Think of it this way: if the compressor is working against a higher pressure in the discharge line, it will need to do more work (higher compression ratio) to get it to that pressure.

This increases the electrical consumption of the motor in the compressor, which adds heat energy. There's also the simple fact that higher pressure = higher temperature on the basic physics side.

If the suction pressure is low, the density of the refrigerant is also lower (again, basic physics), which means that the compression ratio will be higher to get it up to the head pressure, AND lower-density refrigerant won't be able to cool the compressor as well because there just aren't as many refrigerant molecules passing through the compressor crankcase (refrigerant mass flow rate decreases with low suction).

If your suction pressure is low, but the superheat is low (low evaporator airflow or heat load), it can cause LESS of a discharge temp increase than if the suction is low due to low charge, restriction, or evaporator underfeeding. That is simply because the suction temperature is lower, but a low suction temperature is still less important to compressor cooling than a proper mass flow rate. In other words, a correct compression ratio and proper suction pressure are more important to compressor cooling and discharge temperature than suction temperature alone. In commercial refrigeration, compressors may have fans mounted to them to keep the compressor head cooler and manage the compression ratio.

You can also see an increased discharge line temp if you have a high suction superheat at the condenser due to an uninsulated or improperly insulated suction line.

Discharge Superheat

It helps to know the discharge temperature, but we can go a step further and find the discharge superheat to gain some insight into the compressor’s health. Like the suction line, the discharge line also contains superheated vapor. We can get a superheat reading on the discharge line when we compare the discharge line temperature to the saturation temperature of the refrigerant at the given pressure on the discharge line.

The acceptable range for suction superheat will vary by refrigerant and manufacturer, but it’s usually around 20°F. Discharge superheat ranges, however, are a lot higher—a Daikin VRV system with an inverter compressor may have a range from 32°F to 72°F degrees due to the variable-speed nature of the appliance and its range of speeds.

High discharge superheat values (sometimes as high as 100+°F in some cases) require us to look at suction superheat first; we want to ensure that we have enough vapor going into the compressor—verify that the charge has been dialed in properly. If the quality and volume of vapor (suction superheat) entering the compressor inlet are correct, then we’ll know that the additional heat is coming from the compression process, not due to an insufficient supply of vapor to our pump.

At that point, we’ll know that friction within the compressor—and during the compression process—is the source of that additional heat. Compressors require lubrication and use oil for that purpose; in a scroll compressor, we are operating two metal plates sandwiched together at 7,200 RPM. Low oil levels lead to decreased lubrication, more mechanical wear, and more heat in the compression process. We’ll want to look for things that cause compressor damage, such as liquid compression, subsequent oil loss, and possible reasons why oil is not returning to the compressor within our system (over or undercharge) to narrow down the exact problem.

Low discharge superheat, on the other hand, indicates liquid compression. Compressors are not designed to compress liquid; they can only compress vapor. Serious damage may occur when a liquid or a liquid-vapor mixture makes it to the compressor; the oil gets washed out and can’t lubricate the moving parts and dissipate heat, so the compression mechanism (e.g., scroll plates in a scroll compressor) heats up significantly to the point of galling the surface of the scrolls. If you have low suction and discharge superheat, that’s an indication that liquid is getting back to the compressor.

While discharge line temperature is valuable and can give you insight into compression ratios and pressure abnormalities, going a step further to calculate the discharge superheat is also worthwhile. It’s one of our best means of gathering data about the health of the compressor as the vapor undergoes the compression process and comes out the other side. After all, we don’t have a sight glass to see what’s going on inside an operating compressor.

High Head Pressure

On the condenser side, anything that causes a high head will also cause a high discharge line temperature: overcharge, low condenser airflow due to improper motor or blade, or dirty condenser coils. In the case of heat pump units running in heat mode, the most common causes are dirty air filters or other indoor airflow restrictions (because the condenser is now inside during heat mode).

In short, high discharge temp can commonly be caused by:

- Low charge (high suction superheat, low suction pressure, low subcool)

- Severe overcharge

- Low condenser airflow

- Restricted metering devices

- Other restrictions (liquid line drier, suction line drier, kinked lines, clogged screens)

Low discharge line temp can be caused by:

- Overcharge (slight to moderate)

- Low load/airflow (in some cases)

- Compressor not pumping (low compression)

Then, when we go a step further and calculate the discharge superheat, we can get a closer look at the compressor’s health, including oil levels, possible liquid flooding, and mechanical wear.

Keep in mind that keeping the discharge line and compressor temperatures in check will greatly increase compressor longevity with refrigerant-cooled compressors. It is worth noting that severely high compression ratios (low suction, high head) are more common in refrigeration applications as a cause of compressor overheating.

In A/C applications, it is more commonly caused by the high suction temperature/low mass flow rate associated with low charge or restrictions. However, instances of overheating due to dirty coils and poorly insulated suction lines are also quite common.

—Bryan

Comments

How does a severe overcharge cause high discharge temp and slightly overcharge cause low discharge temp? Superheat would be low right? Kind of confused.

How does a severe overcharge cause high discharge temp and slightly overcharge cause low discharge temp? Superheat would be low right? Kind of confused.

Regards. Loads of stuff.

https://git.cloud.leonclassroom.com/tarahquiroz08

Kudos, Fantastic information.

https://git.project.qingger.com/u/veronaquintero

Cheers, Lots of posts!

https://gitiplay.com/@julieratten686?page=about

You explained that well.

https://chessdatabase.science/wiki/User:SadyeZ8092662

Superb facts Many thanks!

https://www.driverscloud.com/fr/actualite/2383/comment-reconnaitre-une-plateforme-de-jeu-en-ligne-securisee

You actually mentioned that really well!

https://employkart.com/employer/camer/

Many thanks, I enjoy it.

https://www.atmasangeet.com/susancorrea821

You stated it well!

https://gitea.hky3535.com/jodiebertrand

Really quite a lot of helpful tips.

http://gitea.yunshanghub.com:8081/naomimcelhaney

You made your stand extremely nicely.!

https://git.rabbittec.com/stacyrountree5

Regards. Loads of stuff.

https://git.cloud.leonclassroom.com/tarahquiroz08

Kudos, Fantastic information.

https://git.project.qingger.com/u/veronaquintero

Cheers, Lots of posts!

https://gitiplay.com/@julieratten686?page=about

You explained that well.

https://chessdatabase.science/wiki/User:SadyeZ8092662

Superb facts Many thanks!

https://www.driverscloud.com/fr/actualite/2383/comment-reconnaitre-une-plateforme-de-jeu-en-ligne-securisee

You actually mentioned that really well!

https://employkart.com/employer/camer/

Many thanks, I enjoy it.

https://www.atmasangeet.com/susancorrea821

You stated it well!

https://gitea.hky3535.com/jodiebertrand

Really quite a lot of helpful tips.

http://gitea.yunshanghub.com:8081/naomimcelhaney

You made your stand extremely nicely.!

https://git.rabbittec.com/stacyrountree5

http://tadalmed.com/# Cialis generique prix

http://tadalmed.com/# Cialis generique prix

acheter kamagra site fiable kamagra gel or Achetez vos kamagra medicaments

https://images.google.com.do/url?sa=t&url=https://kamagraprix.com kamagra 100mg prix

[url=https://images.google.bt/url?sa=t&url=https://kamagraprix.com]kamagra 100mg prix[/url] Kamagra Oral Jelly pas cher and [url=http://www.1moli.top/home.php?mod=space&uid=112191]kamagra gel[/url] achat kamagra

acheter kamagra site fiable kamagra gel or Achetez vos kamagra medicaments

https://images.google.com.do/url?sa=t&url=https://kamagraprix.com kamagra 100mg prix

[url=https://images.google.bt/url?sa=t&url=https://kamagraprix.com]kamagra 100mg prix[/url] Kamagra Oral Jelly pas cher and [url=http://www.1moli.top/home.php?mod=space&uid=112191]kamagra gel[/url] achat kamagra

trouver un mГ©dicament en pharmacie: Medicaments en ligne livres en 24h – Pharmacie en ligne livraison Europe pharmafst.com

trouver un mГ©dicament en pharmacie: Medicaments en ligne livres en 24h – Pharmacie en ligne livraison Europe pharmafst.com

Achat mГ©dicament en ligne fiable pharmacie en ligne france livraison belgique or п»їpharmacie en ligne france

https://maps.google.com.sb/url?q=https://pharmafst.com pharmacie en ligne france livraison internationale

[url=http://www.elienai.de/url?q=https://pharmafst.com]pharmacie en ligne[/url] Pharmacie Internationale en ligne and [url=https://app.guiigo.com/home.php?mod=space&uid=28175]Achat mГ©dicament en ligne fiable[/url] pharmacie en ligne france livraison belgique

Achat mГ©dicament en ligne fiable pharmacie en ligne france livraison belgique or п»їpharmacie en ligne france

https://maps.google.com.sb/url?q=https://pharmafst.com pharmacie en ligne france livraison internationale

[url=http://www.elienai.de/url?q=https://pharmafst.com]pharmacie en ligne[/url] Pharmacie Internationale en ligne and [url=https://app.guiigo.com/home.php?mod=space&uid=28175]Achat mГ©dicament en ligne fiable[/url] pharmacie en ligne france livraison belgique

https://kamagraprix.shop/# kamagra pas cher

https://kamagraprix.shop/# kamagra pas cher

Pharmacie en ligne Cialis sans ordonnance: Cialis sans ordonnance 24h – Tadalafil 20 mg prix sans ordonnance tadalmed.shop

Pharmacie en ligne Cialis sans ordonnance: Cialis sans ordonnance 24h – Tadalafil 20 mg prix sans ordonnance tadalmed.shop

kamagra en ligne: Kamagra Commander maintenant – kamagra en ligne

kamagra en ligne: Kamagra Commander maintenant – kamagra en ligne

olympe casino cresus: olympe – olympe casino cresus

olympe casino cresus: olympe – olympe casino cresus

Great post! Just wanted to confirm the accuracy of the following statement in it: “A high head or low suction pressure can cause a higher discharge line temp. Think of it this way: if the compressor is working against a higher pressure in the discharge line, it will need to do more work (higher compression ratio) to get it to that pressure.” I realize sometimes things are simplified for an example, and get the reader close enough to the concept; however, I wanted to check if this was oversimplified, and may cause a misconception as to the main factors at play in this example. In a scenario where you have a high discharge temp, it’s almost never because the compressor is doing more “work”. In scenario where suction pressure is low, so is the suction line temperature, as a result it picks up more superheat (function of the increased temp difference b/w the pipe and ambient air) than it would if at design press/temp; this superheat is then magnified in the compression of the gas, and shows up as higher discharge pressure. There would also be less volume of refrigerant gas per compression stroke because of the lower pressure/density gas, causing the compressor to actually do less “work”, but operate less efficiently (moves less BTU’s per stroke). In scenario where discharge pressure is higher, the higher disch temp would be simply be a function of the refrigerant press/temp principles, plus superheat.

Great post! Just wanted to confirm the accuracy of the following statement in it: “A high head or low suction pressure can cause a higher discharge line temp. Think of it this way: if the compressor is working against a higher pressure in the discharge line, it will need to do more work (higher compression ratio) to get it to that pressure.” I realize sometimes things are simplified for an example, and get the reader close enough to the concept; however, I wanted to check if this was oversimplified, and may cause a misconception as to the main factors at play in this example. In a scenario where you have a high discharge temp, it’s almost never because the compressor is doing more “work”. In scenario where suction pressure is low, so is the suction line temperature, as a result it picks up more superheat (function of the increased temp difference b/w the pipe and ambient air) than it would if at design press/temp; this superheat is then magnified in the compression of the gas, and shows up as higher discharge pressure. There would also be less volume of refrigerant gas per compression stroke because of the lower pressure/density gas, causing the compressor to actually do less “work”, but operate less efficiently (moves less BTU’s per stroke). In scenario where discharge pressure is higher, the higher disch temp would be simply be a function of the refrigerant press/temp principles, plus superheat.

Acheter Cialis 20 mg pas cher: Cialis en ligne – Cialis sans ordonnance 24h tadalmed.shop

Acheter Cialis 20 mg pas cher: Cialis en ligne – Cialis sans ordonnance 24h tadalmed.shop

To leave a comment, you need to log in.

Log In