Get Tech Tips

Subscribe to free tech tips.

Why (and When) Do We Need Defrost?

Why Defrost?

Let's start with the basics and move on from there. Defrost is necessary when the coil temperature drops below 32°F. Defrost can be as simple as turning the compressor off for a period of time or as elaborate as reversing the flow of refrigerant for the whole system or just parts of the system.

As we were all taught in school, frost buildup is an insulator and prevents heat transfer. Also, airflow through a coil is a big factor. If the coil is iced up, the fans can't move any air, and without air movement, the equipment can't do its job. That applies to all equipment with defrost, really.

Fin spacing

For refrigeration techs, this isn't surprising, but A/C coils ice over a lot faster than refrigeration coils do. Why? Because the fins on a refrigeration coil are much more widely spaced than those on an A/C coil. So, when an A/C coil starts to get cold, and that little bit of frost starts to build on the tube surface and the fin, it affects airflow through the coil much faster than it would if the fins were spaced more widely apart.

Moderate fin spacing medium-temp coil with six fins per inch

Wide fin spacing on a freezer coil four fins per inch

If we had refrigeration coils with fin spacing like an A/C unit, the coils would ice up too quickly, and we couldn't get anything done. The wider fin spacing illustrated shows how refrigeration equipment can run longer between defrost cycles. The evaporator coils are built in such a way to accept a certain amount of frost before the performance starts to degrade.

So, how do we get the job of defrosting done?

The most basic defrost is one we all probably remember: Granny taking everything out of the “icebox,” unplugging it, and going after it with a screwdriver, hairdryer, or an ice pick. Simple, right?

But there has to be a better way, doesn't there?

One of the simplest and most common automatic defrost control strategies is commonly referred to as a “cold control,” more properly called a coil temperature sensing thermostat. You'll sometimes hear it called a “constant cut-in” control.

With either a little coiled bulb on the end of the sensing tube or a tube that kind of embeds in the evaporator, this senses the temperature of the evaporator coil and cycles the compressor based on that. The sequence of events runs like this. Coil temperature rises above cut-in, which is typically in the upper 30s. I like to see about 37°F at the lowest. This setting is nonadjustable, hence the name “constant cut-in.” Control closes, bringing the compressor on. As the coil temperature drops, the control eventually reaches its cut-out point. I've seen this as low as 9°F. The cut-out is what you're adjusting when you adjust the control.

See what's happening? Every single time it cycles off, the coil temperature has to rise above freezing by enough to ensure a good, complete defrost.

You'll see this type of control on stuff like prep tables and smaller, under-counter-type refrigerator units.

Simple and easy.

A similar method for defrost control uses a pressure control for cycling the compressor. With this type of system, you set the cut-in of the control to a saturation pressure equal to the same 37°F to 40°F. Remember, this is saturation temp, not air temp. Adjust the cut-out to maintain the temperature desired.

The big drawbacks of these controls are that they aren't always predictable. The defrost happens when the unit cycles rather than at a specific time (or times) every day. The temperature can also fluctuate over a pretty wide range. For some products, especially fresh meat, wide temperature swings are detrimental to product quality.

Taking a step up from the idea that every off cycle is a defrost, we will just add a timer to the circuit. Now, we can set that timer up to shut the refrigeration off at regular intervals for a specific period. The interval and duration will be situation-dependent, as we'll discuss.

Looking at this mechanical timer, the silver screws in the outer timer ring initiate defrost when they rotate past the pointer at the top left. The defrost ends when the copper-colored pointer on the inner ring rotates past the same pointer.

This digital timer has little black bars on the display, indicating both the time and duration of the defrost. However, the time of day isn't indicated in the photo. In its simplest form, this timer just opens the control circuit to the compressor or the control valve for the set duration of the defrost.

So, what's happening? As far as the system is concerned, the same thing is happening here that was happening before when we used a cold control or a low-pressure switch. We're shutting the refrigeration off and allowing the frost to melt naturally off of the coil. The biggest difference is that with a timer, instead of being subject to the unknown of when the system will cycle off and how long it will take to melt the frost, assuming the time of day is set correctly, you can reliably predict the defrost times. You can say that it defrosts at 6 AM and 6 PM for 45 minutes, and the customer can note that and account for it when checking temps on their equipment.

Let's talk for a minute about how long a defrost needs to last. Obviously, until the coil is completely clear of frost and ice, we need to know when that is.

In most cases, the manufacturer will give guidelines to set your defrost control system up. It will spell out the frequency or interval (time between defrosts) and duration of the defrosts. Because we're trying to maintain proper product temperatures, and we got away from the cold controls and low-pressure controls because they were fluctuating over a wide range of temperatures, we need to look for a way to limit that fluctuation.

For years this was only used on defrosts that added heat to the evaporator coil (which we will look at later) but in recent years, with more stringent product temperature requirements and temperature expectations from the customer, combined with government efficiency mandates, trimming even a few minutes off of a defrost cycles improves both product-holding quality and unit efficiency.

How does it work? The manufacturer will typically install either a thermostat or a temperature sensor on the coil or in the air stream leaving the coil. After experimentation in their labs, they determine just how warm that spot has to be to ensure the coil is free of frost. So, in a hot, humid kitchen in the middle of summer, the defrost runs longer than it does in the middle of winter on an outside-access-only cooler box. Why?

We all learned about sensible and latent heat in school, right? Well, melting frost is just latent heat added to change the state, right? So, since we'll have more frost on a coil with higher humidity than on one in a lower humidity environment, higher frost buildup on a coil will take longer to melt off of that coil, which means that it will take longer to reach that set temperature.

In practice, here's how that timer handles defrost. The time of day initiates a defrost, so, let's say 6 AM. At that time, the timer switches to defrost mode. Internally, that means that the contacts in the timer open to de-energize either the control valve or the compressor. For simple off cycle defrost, the fans continue to run to keep moving air across the coil and accelerate heat transfer. The defrost simply ends when the timer reaches the duration pin, switching the timer contacts back to closed and energizing the load. If we have a termination control, it's a normally OPEN contact that closes on the rise of temperature. So, when that temperature reaches the termination point determined by the manufacturer, the contact closes, energizing a small solenoid in the timer to push the contacts back to the normal position, regardless of the timer position. In an electronic control, this is just another signal input; either digital (NO/NC contact) or analog (sensor) tells the software in the controller to switch the relay back to refrigeration. A coil thermostat or sensor might be set as low as 34°F, while an air sensing control will typically be set between 48 and 55°F.

Electric Defrost

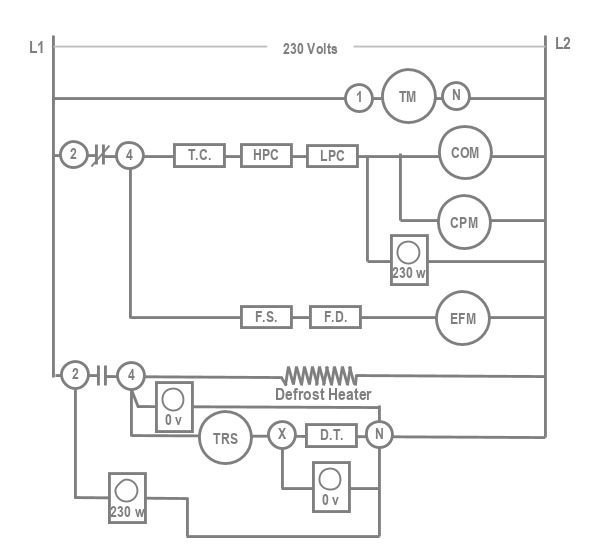

Since some refrigeration equipment runs at temps significantly colder than 32°F sometimes, we’re going to need to add some heat because there simply isn’t enough heat in the refrigerated space to get the frost melted without causing significant damage to the product. The simplest way to add this heat is usually with an electric heater. Let’s take a look at how this adds some complexity to the defrost control system.

The basic timer-type defrost initiation control doesn’t change. The same type of timer is used, and when the defrost initiates, the refrigeration circuit de-energizes—same as before. The big difference now is that, at the same time, we’re energizing a heater that is going to add heat to melt the frost off the evaporator coil. In the case of most pieces of equipment, we’re also going to de-energize the evaporator fan circuit. That is to keep the heat concentrated where it is needed to do the job in as little time as possible. We also don't want to blow hot, humid air around the refrigerated space.

Defrost termination is really the standard for this type of system. Almost all electric defrost systems will have a type of built-in defrost termination. The most common controls are referred to as DTFD (defrost termination fan delay) or three-wire controls. This dual-purpose control handles both defrost termination, obviously, and post-defrost fan delay, which we'll get to in a minute or two. The DTFD is normally attached to one side of the evaporator coil in a position that takes the longest to get warm during defrost. This way, the coil gets the best possible defrost.

Refrigeration is off; heaters are on, frost is melting away. All is well. Once our DTFD control sees its high event temperature, usually about 55°F, it closes the part of the circuit to terminate defrost—same as before. The refrigeration machine starts back up, and we're moving heat again, but wait…

What about the fans? They aren't running. Quick! Get a meter and a ladder…

We're talking about the other half of the DTFD control. We've terminated defrost (DT). Now, we have to wait a couple of minutes until the coil temperature drops below freezing. We have to remember that the coil was just 55°F, and there is some humid air still trapped in that sheet metal box up there. Slam the fans on right now, and you'll have a wintery Wonderland in your freezer with icicles and snow all over in a week or so. Wait a minute or two, and the coil will freeze that last bit of moisture. When the coil temp drops to around 30°F at the control, our fans will restart.

Gas defrost, particularly for large refrigeration systems, will require an entire article in and of itself to cover in any depth. I will try to summarize it in a paragraph or two and give it a more thorough treatment in the future.

These, like all other defrosts, operate on a time basis. The systems where this is more common aren't single systems but multiplex systems with multiple evaporators operating on different schedules. When one goes into defrost, the rest continue to run in refrigeration.

When the timer initiates a defrost, a few things happen all at once. A differential valve de-energizes to create a pressure differential to allow flow in reverse. To create a section of reversed gas flow, the system uses two actuating valves—one that stops suction gas flow to the compressor and another that dumps hot discharge gas into that suction line, sending superheated discharge gas out to the evaporator where it rejects its heat to the frost on the lines and is condensed just like in a heat pump. It returns to the system through a check valve piped around the TEV—the same as with a heat pump. Without the pressure differential, the hot gas cannot flow properly through the check valve.

Once either the time limit or the termination temperature is reached, all of those valves return to their normal positions, and the refrigeration cycle resumes normally.

—Jeremy Smith CMS

Comments

Keep these articles coming Jeremy…good stuff.

Keep these articles coming Jeremy…good stuff.

The Audemars Piguet Royal Oak 16202ST features a elegant stainless steel 39mm case with an extra-thin design of just 8.1mm thickness, housing the advanced Calibre 7121 movement. Its mesmerizing smoked blue gradient dial showcases a signature Petite Tapisserie pattern, fading from golden hues to deep black edges for a dynamic aesthetic. The iconic eight-screw octagonal bezel pays homage to the original 1972 design, while the scratch-resistant sapphire glass ensures clear visibility.

https://linktr.ee/apro15202stwow

Water-resistant to 5 ATM, this “Jumbo” model balances robust performance with luxurious refinement, paired with a stainless steel bracelet and secure AP folding clasp. A modern tribute to horological heritage, the 16202ST embodies Audemars Piguet’s craftsmanship through its precision engineering and evergreen Royal Oak DNA.

The Audemars Piguet Royal Oak 16202ST features a elegant stainless steel 39mm case with an extra-thin design of just 8.1mm thickness, housing the advanced Calibre 7121 movement. Its mesmerizing smoked blue gradient dial showcases a signature Petite Tapisserie pattern, fading from golden hues to deep black edges for a dynamic aesthetic. The iconic eight-screw octagonal bezel pays homage to the original 1972 design, while the scratch-resistant sapphire glass ensures clear visibility.

https://linktr.ee/apro15202stwow

Water-resistant to 5 ATM, this “Jumbo” model balances robust performance with luxurious refinement, paired with a stainless steel bracelet and secure AP folding clasp. A modern tribute to horological heritage, the 16202ST embodies Audemars Piguet’s craftsmanship through its precision engineering and evergreen Royal Oak DNA.

Данный ресурс — цифровая витрина независимого аналитической компании.

Мы организуем сопровождение в решении деликатных ситуаций.

Группа профессионалов работает с максимальной дискретностью.

Мы берёмся за сбор информации и детальное изучение обстоятельств.

Нанять детектива

Каждое дело получает персональный подход.

Мы используем современные методы и работаем строго в рамках закона.

Ищете достоверную информацию — вы нашли нужный сайт.

Данный ресурс — цифровая витрина независимого аналитической компании.

Мы организуем сопровождение в решении деликатных ситуаций.

Группа профессионалов работает с максимальной дискретностью.

Мы берёмся за сбор информации и детальное изучение обстоятельств.

Нанять детектива

Каждое дело получает персональный подход.

Мы используем современные методы и работаем строго в рамках закона.

Ищете достоверную информацию — вы нашли нужный сайт.

You guys are fantastic, really appreciate what you are doing. Keep up the good work!!

You guys are fantastic, really appreciate what you are doing. Keep up the good work!!

To leave a comment, you need to log in.

Log In