Get Tech Tips

Subscribe to free tech tips.

What I’ve Learned From Teaching in a Trade School

I have been teaching at my local trade school as an HVAC instructor for the past year. It’s been a much different experience than training a technician on the job. Some of the students are already working in the field, and others have never been in an attic or crawl space. But regardless of experience or background, I’ve learned a few things from these past two semesters that could be of great use to trainers teaching new techs and the trade as a whole.

I happen to be teaching the very subjects that were hardly talked about when I was in trade school. That in itself is a joy because they are the very things on which technicians across the nation could use more training: airflow, psychrometrics, combustion analysis, duct design, load calculations, and indoor air quality (IAQ). Unfortunately, these topics have never really been included in the “essential” curriculum at this particular trade school. Of course, instructors always touched on those topics, but most of the time was spent teaching the students how to do other things.

All of those other things were absolutely appropriate and needed for the students to become quality technicians. Also, since so many students were green, the more complex concepts and practices weren’t emphasized as much. That has been the way things worked for a long time, and it’s understandable, but our class took a different approach this year.

None of the graduating students this year are currently capable of running a room-to-room load calculation of a residential building. They cannot design a duct system or solve air pressure imbalance issues. They received all the necessary information, of course, but it’s really an overload of complex information that takes at least a year per topic to really get a good handle on.

However, the goal wasn’t to make all the students experts in these topics right away. The goal was to really emphasize the importance and practicality of knowing these topics intimately as a service technician. If these new technicians enter the field with an understanding that there are these vital facets to our work, they will (hopefully) eventually grow beyond the “average tech” and begin the path toward the rare “unicorn tech.”

As trainers and service managers, business owners, and senior techs, we can do the same thing wherever we are in our work. A great tragedy in the trade is the idea that many technicians have what Jim Bergmann calls “appliance fixation.” It requires a mentality shift for a technician to realize that there are more complex solutions to solve complex problems as opposed to treating the symptoms of an issue. People in a training role of any kind have the opportunity to instill a sense of excitement and energy about this in technicians. The reality is that if any technician can really understand any of the above subjects, even the design concepts, they will be able to identify and solve more problems than most.

How do you know what’s wrong if you don’t know what right is in the first place?

Aside from the topics already mentioned, we should place an enormous sense of importance on the idea that technicians should learn more about physics and human physiology. We are, as HVAC technicians, ultimately in the business of human comfort and health, after all.

So, how does this look in practice? I liked to use examples from my own experience and stories from other technicians’ experiences that really helped illustrate what happens when certain facets of the trade get ignored (i.e., symptoms of oversized equipment, bad duct design, occupant health issues, etc.).

We also played a game that Bryan Orr has spoken about several times, as this is also a training exercise we implement at Kalos for new technicians. I think it’s officially called The Diagnostic Game. A trainer simply comes up with a service call in their head, all the symptoms, the root cause, etc. Then, the technician-in-training will go step by step into the call, asking questions such as the following:

- “Is the thermostat set properly?”

- “Is the fan operating?”

- “Is the coil dirty?”

- “What’s the outdoor ambient temperature?”

Not only do the trainees get experience with critical thinking and problem solving, but the trainer gets the opportunity to guide them through the call gently and explain why a certain question they’ve asked may or may not be relevant.

So, as we enter this next summer season, I encourage technicians to pick a topic from the list of subjects we focused on in class and really hone in on it for the rest of the year. We have tons of training information on each and links to resources from other experts and partners. All the time, Bryan talks about how one of the joys of this trade is that there is never really a place where one can “arrive” as a service technician. There’s always more to learn. The nuances of human comfort are immense!

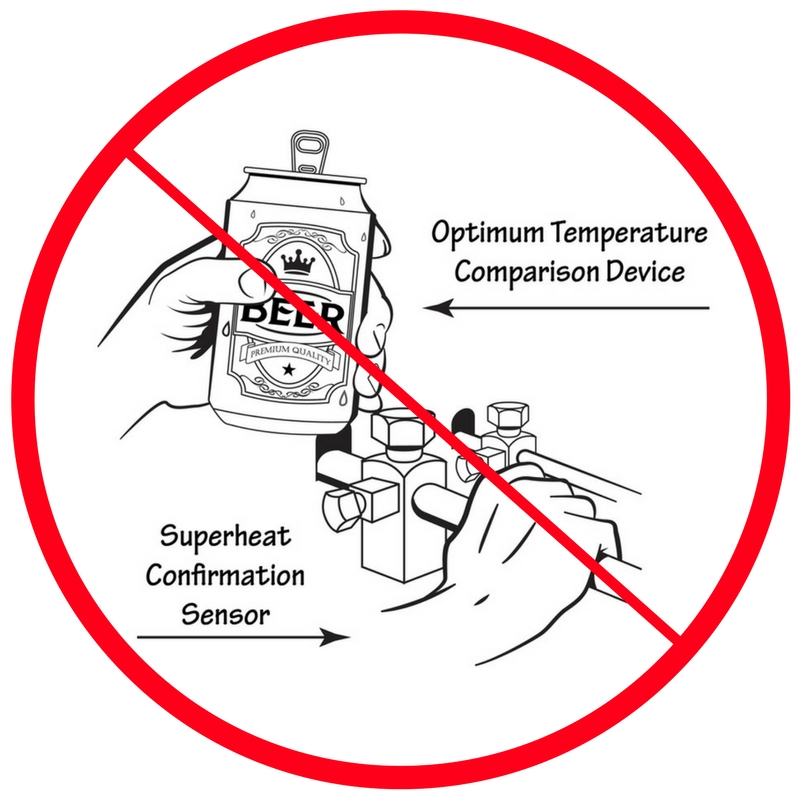

Grab a cold one after a long day, sit back on the couch, and watch a playlist of training videos on your topic of choice.

Never stop learning!

—Kaleb

Comments

Well said and what wonderful insight into what it is like teaching the future techs of our industry. I too have recently taken on the role of High School HVAC instructor and what you mentioned here is so vital to the growth of these technicians. I applaud your step in the teaching world and kudos my friend to taking that leap. These posts are wonderful and I learn something every time I read them. Even after 27 years in the industry, I never stop learning. Thank you all for every thing you do for our industry!

Well said and what wonderful insight into what it is like teaching the future techs of our industry. I too have recently taken on the role of High School HVAC instructor and what you mentioned here is so vital to the growth of these technicians. I applaud your step in the teaching world and kudos my friend to taking that leap. These posts are wonderful and I learn something every time I read them. Even after 27 years in the industry, I never stop learning. Thank you all for every thing you do for our industry!

Learn something new every day and apply what you learn simple / complex.

Learn something new every day and apply what you learn simple / complex.

To leave a comment, you need to log in.

Log In