Get Tech Tips

Subscribe to free tech tips.

W1, W2, & E

I got this question via email (edited slightly for length):

Some things I've done because I've been taught to do them yet I don't know why I do them. One of those things is putting a jumper between w1/e and w2. Sometimes, in the case of a Goodman for example, I've been taught to combine the brown wire along all the whites at the air handler. Do you mind just clarifying the whole situation with w1/e jumped to w2? And also maybe x2 on some stats? Thanks for your help.

— J

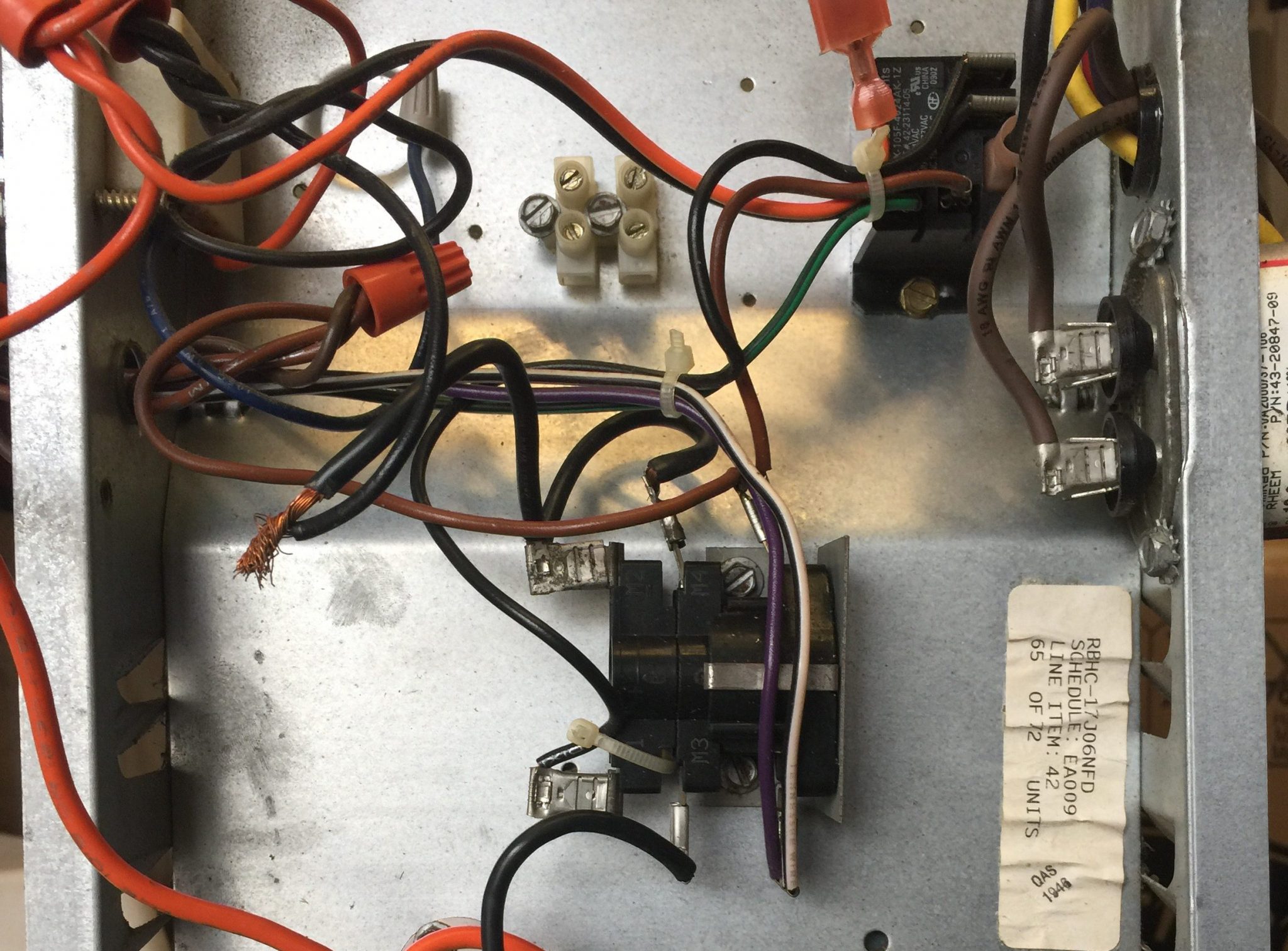

Back in the early 2000s, when I was the lead trainer for another company, some of the most common miswiring issues had to do with electric heat. So much so that I created a bunch of different wiring diagrams with a fancy program called “Microsoft Paint” to illustrate how to wire different combinations of equipment. Here is one of them:

In older thermostats (older than the diagram shown here), there were no installer setup programs where you could designate the type of system the thermostat was connected to. Each terminal performed a particular universal function, and you would configure the operation based on how you wired it up. Which terminals you connected and where, which ones you left open, and sometimes, which ones you jumpered out.

So, first, let's give a quick look at the meaning of each terminal:

W – When you see a W terminal, it just means heat. Usually, you will only see W when the control only has one stage of heat.

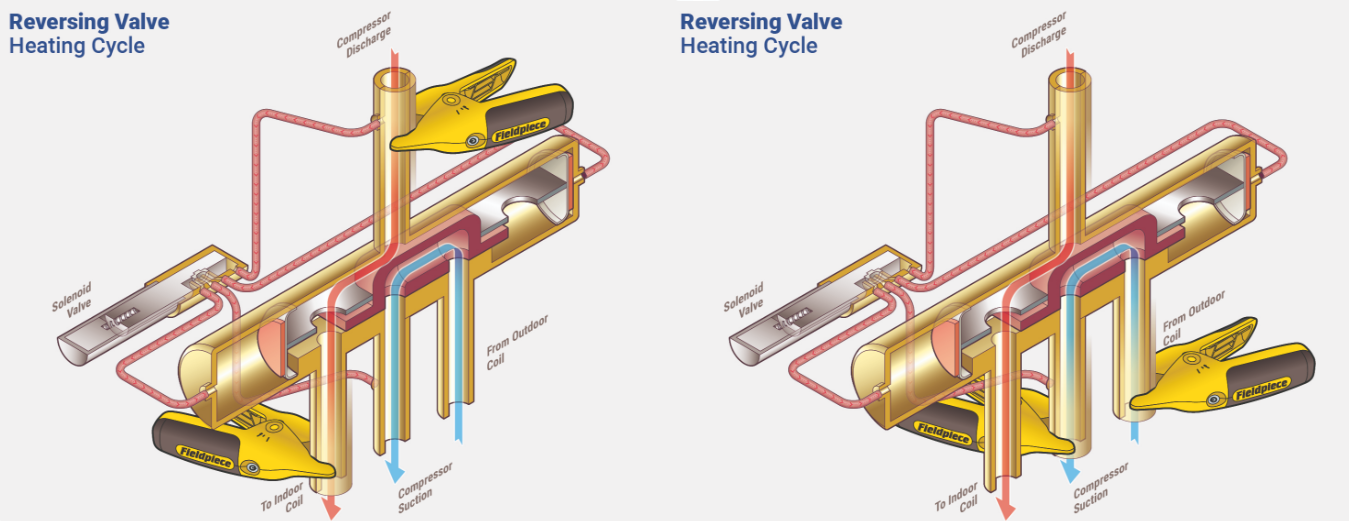

W1 – Means first-stage heat. In a heat pump, first-stage heat is the same as the first-stage cool. It just means the contactor/compressor is turning on. Whether that is heat or cool is actually dictated by whether or not the O/B terminal is energized. That is why, on many old thermostats, you would jumper Y1 and W1 in a heat pump application.

W2 – Means second-stage heat. It could be the first stage of heat strips in a common southern heat pump, the gas furnace backing up the heat pump in a modern “hybrid heat” application, or just a second heat strip bank in the case of a straight electric system. W2 is generally called on based on a temperature differential between setpoint and space, outdoor temperature, or run time.

W3 – This is just the next stage of heat after W2.

E – Is emergency heat, usually just a way to manually drive on what would normally be the secondary form of heat without stage 1 heating.

Emergency heat only makes sense when there is some sort of secondary heat source. Even then, it only helps if the secondary heat source is sufficient to heat the space, as in the case when the secondary is a furnace, Hydronics, or a large heat kit. In Florida, most of our units have 5KW auxiliary heat, which will never be sufficient to heat a home in an “emergency.”

Many of these other terminal designations are a holdover from a time when all the controls in the thermostat and defrost board were electromechanical. Much of it was for indication/trouble lights, and some of it was for the thermostat to perform staging based on outdoor temperature because run-time logic was not available. So, for your X2 question, have a look at the thermostat and diagram below.

In the modern thermostat, they have usually relegated these staging configurations and terminal designations into the installer setup, and every thermostat is a little different. In general, in the south, we jumper W2 to E because they truly are the same. In some cases, this does nothing; in others, it just ensures that the aux heat comes on quicker if the user chooses emergency heat.

Are there some cases where emergency heat could be totally different than aux heat? I'm sure; I have just never seen one personally. Like usually, it all comes down to knowing your particular piece of equipment and your controls; reading the installation instruction is a good first step.

—Bryan

Comments

A good answer for a good question , as a installer myself I like to know exactly what function of each part I install to know exactly how it operates.

A good answer for a good question , as a installer myself I like to know exactly what function of each part I install to know exactly how it operates.

The ClothOff io app is constantly updated with new features. The undress ai app market is booming, and ClothOff leads the pack. I had no issues with ClothOff login—smooth and secure. The undress io free version of https://nightspirit.ru/ is perfect for testing.

The ClothOff io app is constantly updated with new features. The undress ai app market is booming, and ClothOff leads the pack. I had no issues with ClothOff login—smooth and secure. The undress io free version of https://nightspirit.ru/ is perfect for testing.

El libro que revoluciona el desarrollo personal con un enfoque científico y práctico. https://comomandaralamediadeformaeducadapdf.cyou/ PDF completo disponible para descarga inmediata y gratuita.

El libro que revoluciona el desarrollo personal con un enfoque científico y práctico. https://comomandaralamediadeformaeducadapdf.cyou/ PDF completo disponible para descarga inmediata y gratuita.

How to create a low-waste kitchen without giving up convenience https://ecofriendlystore.ru/

How to create a low-waste kitchen without giving up convenience https://ecofriendlystore.ru/

Easy DIY projects for a plastic-free, low-waste home https://ecofriendlystore.ru/

Easy DIY projects for a plastic-free, low-waste home https://ecofriendlystore.ru/

How to make your workspace more sustainable https://ecofriendlystore.ru/

How to make your workspace more sustainable https://ecofriendlystore.ru/

How to make your coffee routine more sustainable https://ecofriendlystore.ru/

How to make your coffee routine more sustainable https://ecofriendlystore.ru/

How to host a zero-waste party or gathering https://ecofriendlystore.ru/

How to host a zero-waste party or gathering https://ecofriendlystore.ru/

Save money while going green – here’s how to make sustainability affordable https://ecofriendlystore.ru/

Save money while going green – here’s how to make sustainability affordable https://ecofriendlystore.ru/

Why buying secondhand is one of the greenest choices you can make https://ecofriendlystore.ru/

Why buying secondhand is one of the greenest choices you can make https://ecofriendlystore.ru/

Eco-friendly alternatives to paper towels and napkins https://ecofriendlystore.ru/

Eco-friendly alternatives to paper towels and napkins https://ecofriendlystore.ru/

Honest reviews of zero-waste products that actually work in real life https://ecofriendlystore.ru/

Honest reviews of zero-waste products that actually work in real life https://ecofriendlystore.ru/

Why reusable period products are worth the switch https://ecofriendlystore.ru/

Why reusable period products are worth the switch https://ecofriendlystore.ru/

A guide to refillable and package-free household products https://ecofriendlystore.ru/

A guide to refillable and package-free household products https://ecofriendlystore.ru/

A guide to refillable and package-free household products https://ecofriendlystore.ru/

A guide to refillable and package-free household products https://ecofriendlystore.ru/

Why “less but better” is the core of true sustainability https://ecofriendlystore.ru/

Why “less but better” is the core of true sustainability https://ecofriendlystore.ru/

Step-by-step guides to sewing reusable bags, wraps, and more https://ecofriendlystore.ru/

Step-by-step guides to sewing reusable bags, wraps, and more https://ecofriendlystore.ru/

Discover everyday swaps that cut plastic, save money, and help the planet https://ecofriendlystore.ru/

Discover everyday swaps that cut plastic, save money, and help the planet https://ecofriendlystore.ru/

Sustainable alternatives to popular household cleaning brands https://ecofriendlystore.ru/

Sustainable alternatives to popular household cleaning brands https://ecofriendlystore.ru/

How to choose truly sustainable kitchenware and cookware https://ecofriendlystore.ru/

How to choose truly sustainable kitchenware and cookware https://ecofriendlystore.ru/

Reusable alternatives that pay for themselves in just a few months https://ecofriendlystore.ru/

Reusable alternatives that pay for themselves in just a few months https://ecofriendlystore.ru/

How to create a zero-waste first aid kit https://ecofriendlystore.ru/

How to create a zero-waste first aid kit https://ecofriendlystore.ru/

Stories from real people building sustainable habits one step at a time https://ecofriendlystore.ru/

Stories from real people building sustainable habits one step at a time https://ecofriendlystore.ru/

How to reduce energy use at home without major renovations https://ecofriendlystore.ru/

How to reduce energy use at home without major renovations https://ecofriendlystore.ru/

How to dispose of electronics and batteries responsibly https://ecofriendlystore.ru/

How to dispose of electronics and batteries responsibly https://ecofriendlystore.ru/

Science-backed advice on what really makes a difference for the environment https://ecofriendlystore.ru/

Science-backed advice on what really makes a difference for the environment https://ecofriendlystore.ru/

You organized this well https://shopforhome.ru/

You organized this well https://shopforhome.ru/

https://six6sabd.online

https://six6sabd.online

They have to be saved away from any perfume sprays and water in order for you the shine to remain.

They have to be saved away from any perfume sprays and water in order for you the shine to remain.

If I have an older system that includes W1 W2 and a Y1 how can I install these on my new thermostat. There are places for all of my labled wires but I always encounter the note “if you have w1, w2, and y1 cables, you need to consult a technician… I have model number available if this helps. Thank you.

If I have an older system that includes W1 W2 and a Y1 how can I install these on my new thermostat. There are places for all of my labled wires but I always encounter the note “if you have w1, w2, and y1 cables, you need to consult a technician… I have model number available if this helps. Thank you.

Also looking for an answer on this. Would greatly help! Thanks.

Also looking for an answer on this. Would greatly help! Thanks.

Wow, I have the issues gentleman. my old thermostat has have w1, w2, and y1 cables,

how can I install these on my new thermostat? my guess jumping it out.

Wow, I have the issues gentleman. my old thermostat has have w1, w2, and y1 cables,

how can I install these on my new thermostat? my guess jumping it out.

Ok, I think I’m putting it all together now but can I get this confirmed?

On the outside unit, I have O, Y, E, AND W2 connected in addition to C(ommon) R for power and G for fan

On the thermostat, E is going to a terminal labeled W/E

then O (reversing valve) going to a terminal labeled O/B

and finally, W2 going to a terminal also as W2.

No W1 anywhere on the outside, but Y actually takes it’s place for normal/1st stage heat? But also why would E and W2 be separated?

Outside unit model number is a Carrier 38YG024300. TIA!

Ok, I think I’m putting it all together now but can I get this confirmed?

On the outside unit, I have O, Y, E, AND W2 connected in addition to C(ommon) R for power and G for fan

On the thermostat, E is going to a terminal labeled W/E

then O (reversing valve) going to a terminal labeled O/B

and finally, W2 going to a terminal also as W2.

No W1 anywhere on the outside, but Y actually takes it’s place for normal/1st stage heat? But also why would E and W2 be separated?

Outside unit model number is a Carrier 38YG024300. TIA!

Upon closer inspection of the Schematics ( Link at bottom ), and the fact that your question regarding why the E would be separate from the W2 was most likely directed at the Defrost Board terminals, I would like to clarify my previous response. The Defrost Board schematics for the 38YG show that the W2 Terminal is the terminal wired to the Defrost Relay & Logic circuit. This actually allows the Defrost Board to energize the W2 Stage 2 Heat in the Air Handler, when the heat pump is in defrost mode to supplement heat generation and/or warm the cooler air that is passing through the air handler when the defrost mode reverse valve activates during defrost to bring heat to the outside coil.

The schematics show that by default the Air Handler/Heat Strip terminal W2/E/W3 are normally jumped together, however the Terminals on the Defrost board are probably there to allow for them to be jumped from W2 to E or W3 in the event the installation might make use of them in a non default configuration, as the Defrost Board schematics show no physical circuits connected to the E and W3 terminals by default. My 38YG Defrost Board has a connection to W2 and a connection to E Terminals, and my Air Handler Heat Strip Terminals jump the E with W2. I have learned while installing my new heat strip that the E is jumped to the W2 on the heat strip to allow the Heat Strip Circuit to control a default activation of the indoor Fan Motor when (the thermostat) is in Emergency Heat mode, as some Thermostats (White Rodgers 1F58) don’t energize the G for the Indoor Fan Relay when in Emergency heat mode. https://drive.google.com/drive/folders/1CRj10rYBgYnPiwFBgId_FDdo8cOIAKVO?usp=sharing

Upon closer inspection of the Schematics ( Link at bottom ), and the fact that your question regarding why the E would be separate from the W2 was most likely directed at the Defrost Board terminals, I would like to clarify my previous response. The Defrost Board schematics for the 38YG show that the W2 Terminal is the terminal wired to the Defrost Relay & Logic circuit. This actually allows the Defrost Board to energize the W2 Stage 2 Heat in the Air Handler, when the heat pump is in defrost mode to supplement heat generation and/or warm the cooler air that is passing through the air handler when the defrost mode reverse valve activates during defrost to bring heat to the outside coil.

The schematics show that by default the Air Handler/Heat Strip terminal W2/E/W3 are normally jumped together, however the Terminals on the Defrost board are probably there to allow for them to be jumped from W2 to E or W3 in the event the installation might make use of them in a non default configuration, as the Defrost Board schematics show no physical circuits connected to the E and W3 terminals by default. My 38YG Defrost Board has a connection to W2 and a connection to E Terminals, and my Air Handler Heat Strip Terminals jump the E with W2. I have learned while installing my new heat strip that the E is jumped to the W2 on the heat strip to allow the Heat Strip Circuit to control a default activation of the indoor Fan Motor when (the thermostat) is in Emergency Heat mode, as some Thermostats (White Rodgers 1F58) don’t energize the G for the Indoor Fan Relay when in Emergency heat mode. https://drive.google.com/drive/folders/1CRj10rYBgYnPiwFBgId_FDdo8cOIAKVO?usp=sharing

Hi Jerry, I have been working/learning about my carrier 38YG024300 as well recently.

The Y Terminal is energized by the thermostat when it is calling for 1st stage cooling or heating. Most heat pumps default (no “O’ Reversing Valve) to running as 1st stage heat (W1) when the Y Terminal is energized. So yes 1st stage heat (W1) is the Default running mode of the 38YG with Y energized.

As for why E and W2 would be separated I believe is primarily due to most thermostats, when in Emergency Heat mode, do not energize Y (Compressor). W2 (Second Stage Heat) is typically used with (in conjunction with) the heat pump (Y Compressor) when the thermostat is set for regular heat. The supports 2nd stage (W2) heat to run while the Heat Pump is in defrost mode, or when a thermostat set temperature is at a level that exceeds a certain amount from the current real temperature so as to help reduce the heating time to the set target temperature. Emergency modes on thermostats typically energize just the E wire (Without the Y calling for the compressor to run). It’s a good idea to run in Emergency heat mode when you know your Heat Pumps specifications indicate that the temperature outside is below a level it is capable of collecting much heat from, and/or when you might expect that ice could freeze up your outdoor fan motor. I think the 38YG (7 Seer?) series is capable down to ~30 Degrees, and then it becomes less efficient at extracting heat… so that is when I normally would change the thermostat to Emergency Heat so that the outdoor Compressor and Fan don’t run. Newer heat pumps are more efficient at lower temperatures so one would need to consult the manual to determine when Emergency heat might be the better setting. Some systems automatically choose modes using outdoor & sensors. I would like to inquire with you regarding a component in your outdoor 38YG024300 unit. It’s the Start Assist PTC that is mounted above the Dual Run capacitor on the rear wall of the inner component compartment. Mine is Blue and has print on it that says Cera-Mite. I am looking for the part number on the device that starts with HC95XX followed by 3 Numbers and/or something like 305Cxx . Many of the parts suppliers are calling for a slightly different PTC Rating than the one that is currently in my unit, and I wondered if the one I have was a replacement that a past technician used because it was the only one he had, or if the one I have was actually at the rating carrier originally specified when these units were manufactured 30 years ago… I would really appreciate it if you wouldn’t mind telling me what your Cera Mite’s PTC part number is so we can compare.

I Just recently replaced my Heat Strip in my indoor air handler 40AQ030 310BU and it has been quite a learning experience. Thanks! Roger

Hi Jerry, I have been working/learning about my carrier 38YG024300 as well recently.

The Y Terminal is energized by the thermostat when it is calling for 1st stage cooling or heating. Most heat pumps default (no “O’ Reversing Valve) to running as 1st stage heat (W1) when the Y Terminal is energized. So yes 1st stage heat (W1) is the Default running mode of the 38YG with Y energized.

As for why E and W2 would be separated I believe is primarily due to most thermostats, when in Emergency Heat mode, do not energize Y (Compressor). W2 (Second Stage Heat) is typically used with (in conjunction with) the heat pump (Y Compressor) when the thermostat is set for regular heat. The supports 2nd stage (W2) heat to run while the Heat Pump is in defrost mode, or when a thermostat set temperature is at a level that exceeds a certain amount from the current real temperature so as to help reduce the heating time to the set target temperature. Emergency modes on thermostats typically energize just the E wire (Without the Y calling for the compressor to run). It’s a good idea to run in Emergency heat mode when you know your Heat Pumps specifications indicate that the temperature outside is below a level it is capable of collecting much heat from, and/or when you might expect that ice could freeze up your outdoor fan motor. I think the 38YG (7 Seer?) series is capable down to ~30 Degrees, and then it becomes less efficient at extracting heat… so that is when I normally would change the thermostat to Emergency Heat so that the outdoor Compressor and Fan don’t run. Newer heat pumps are more efficient at lower temperatures so one would need to consult the manual to determine when Emergency heat might be the better setting. Some systems automatically choose modes using outdoor & sensors. I would like to inquire with you regarding a component in your outdoor 38YG024300 unit. It’s the Start Assist PTC that is mounted above the Dual Run capacitor on the rear wall of the inner component compartment. Mine is Blue and has print on it that says Cera-Mite. I am looking for the part number on the device that starts with HC95XX followed by 3 Numbers and/or something like 305Cxx . Many of the parts suppliers are calling for a slightly different PTC Rating than the one that is currently in my unit, and I wondered if the one I have was a replacement that a past technician used because it was the only one he had, or if the one I have was actually at the rating carrier originally specified when these units were manufactured 30 years ago… I would really appreciate it if you wouldn’t mind telling me what your Cera Mite’s PTC part number is so we can compare.

I Just recently replaced my Heat Strip in my indoor air handler 40AQ030 310BU and it has been quite a learning experience. Thanks! Roger

Trying to install C-wire adapter in Trane furnace/ac for T5 honeywell thermostat. Wiring in Trane terminal from left to right: W2 – jumper wire – W1 (white wire also connected to W1) R (red wire connected) G (green wire connected) B/C (blue wire connected) Y2 (nothing connected) Y1 (yellow wire connected) – jumper wire – O

For C-wire install I did this: W (from terminal) to W (adapter), R (terminal) to R (adapter) , G (terminal) to C (adapter), and Y1 (terminal) to K (adapter) and pulled B/C wire from terminal and capped it. Wires from the C-wire to terminal: W to W1, G to G, C to B/C, Y to Y1 and I left the jumper wires as they were (W2-W1 and Y1-O)

When doing it this way the thermostat is powered on and air will blow, but the outdoor Trane unit does not turn on/run to cool the house…

What am I doing wrong?

Trying to install C-wire adapter in Trane furnace/ac for T5 honeywell thermostat. Wiring in Trane terminal from left to right: W2 – jumper wire – W1 (white wire also connected to W1) R (red wire connected) G (green wire connected) B/C (blue wire connected) Y2 (nothing connected) Y1 (yellow wire connected) – jumper wire – O

For C-wire install I did this: W (from terminal) to W (adapter), R (terminal) to R (adapter) , G (terminal) to C (adapter), and Y1 (terminal) to K (adapter) and pulled B/C wire from terminal and capped it. Wires from the C-wire to terminal: W to W1, G to G, C to B/C, Y to Y1 and I left the jumper wires as they were (W2-W1 and Y1-O)

When doing it this way the thermostat is powered on and air will blow, but the outdoor Trane unit does not turn on/run to cool the house…

What am I doing wrong?

Ethical fashion tips: how to shop less and choose better https://ecofriendlystore.ru/

Ethical fashion tips: how to shop less and choose better https://ecofriendlystore.ru/

To leave a comment, you need to log in.

Log In