Get Tech Tips

Subscribe to free tech tips.

VRV/VRF Installation Tips

This tech tip was written by experienced tech and VRF/VRV specialist Ryan Findley. Thanks, Ryan! (Note: Ryan refers to VRV rather than VRF because he specializes in Daikin, and these articles are written from a Daikin VRV perspective. He also wrote a great introductory guide to VRV systems, which you can find here.)

In this tech tip, I’ll be going over a few things related to the installation of VRV systems.

THIS IS NOT MEANT TO TAKE THE PLACE OF A FACTORY-PROVIDED INSTALLATION CLASS.

Any questions should be directed to your rep sales engineer or the manufacturer's specific instructions. It’s better to ask and double-check than to have to do something twice.

The install is the most critical part of a successful system; you will not get desirable results without a quality install. Many issues can arise from install issues, but here are a few of the most common ones.

Leaks and Tightness Test

Flares. I know—everyone hates them, but a properly made and installed flare is an effective mechanical joint. Be sure to ream (deburr) the tubing; use your flare sizing guide tool to assure the flare is a good flare. I have made my fair share of flares that looked good but didn’t pass the test with the gauge. If you don’t have one, you need one. The link to the one I use will be at the bottom. Also, be sure to use a torque wrench and torque all flares to the appropriate torque specs. I have come across many of them that leak after the change of season with the corresponding expansion and contraction. Often, they’ll last 3-6 months before they start to leak.

Be sure to complete the tightness test per the install procedure, with the finishing pressure being 550 psi (450 for the FXTQ) for 24 hours or more. Be sure to record your test pressure and temperature at the beginning and end, and compensate for pressure change based on changes in ambient temperature.

Notes from Bryan: The HVAC School app is free and has a nitrogen pressure change calculator. Also, in my contracting business, we find that using a good, quality, modern flaring tool (with a depth gauge and clutch) and some assembly lubricant such a refrigerant oil or Nylog can really help make a great, tight-fitting flare with less galling.

Refnets

Be sure to mount your refnets within the allowable angle, 15 degrees for outdoor refnets and 30 degrees for indoor refnets. If you’re interested in why this matters, see this video.

Finishing Vacuum

Be sure to get below 500 microns and hold. A new and tight system should easily be able to get down under 300 and hold there. If not, then you want to investigate further.

Pipe Insulation

Make sure you use insulation with an outside diameter of at least ¾”. If line sets run through an attic or unconditioned space, this is especially important. Be sure to seal the joints with appropriate glues or tapes designed for the purpose.

Purge & Flow Nitrogen

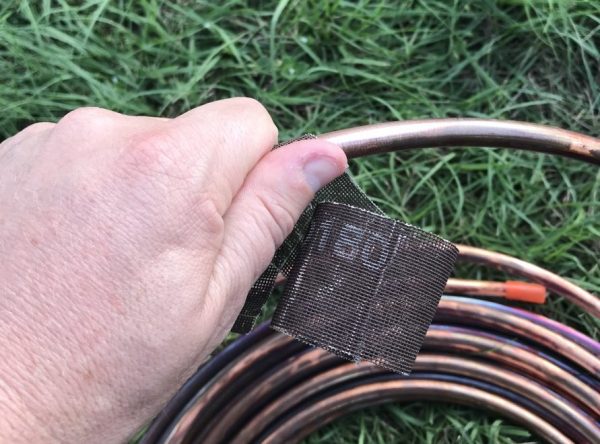

You must displace all air with nitrogen by purging first, then flow nitrogen at a very low rate anytime you are brazing. There are filters/strainers everywhere in the system that are fine mesh that can be clogged up very easily. See pictures below.

Moisture

Moisture can be a major issue with the use of PVE oil. PVE is more hygroscopic than POE, but rather than hydrolysis occurring, it changes into a sludge. This sludge can gum up mechanical components in the refrigeration system, which can cause premature failures. Be sure to complete a decay test after you have reached your finishing vacuum; it’ll tell if there’s moisture in the system or not.

Communication wiring

Be sure to daisy-chain your wiring. Also, make sure to use non-shielded 18/2 stranded wire (or whatever your particular product requires) and install it according to the submittals from your sales engineer.

Setting The Units

Verify that the units are set in the proper order; the largest unit goes closest to the indoor units down to the smallest unit (VRV 4). VRV 3 has a crossover line that goes between the modules, so this is not a concern.

20/40 Rule

If you want to reduce refrigerant noise, it’s recommended to keep the first elbow after a refnet at least 20” away and 40” away for branch boxes.

Line Length Measurements

Please, please, please keep track of and measure the line set!

Send it to your sales engineer so that the correct additional charge can be calculated. These are critical charge machines, so every pound matters.

Oil Traps

Only inverted traps are allowed in the VRV piping. Oil traps are a major concern for these machines, as the machines cannot overcome them in oil return mode. As more oil gets trapped out in the system, you’ll eventually start losing bearings in the compressors. I have changed many compressors that have had nearly no oil left in them. Be mindful of keeping piping on the same level. There are specific rules about oil traps in your install class.

Expansion Joints

Install expansion joints per your sales engineer requirements. This is important because of the possibility of a large change in temperature that the pipe is under and needs to be allowed to expand and contract. If not, there’s a possibility of blowing out the end of a fitting.

Pipe Clamps

Do NOT tighten your pipe clamps down with your impact driver. The pipe needs the ability to move; otherwise, there’s a chance you can blow out a fitting.

Unit Placement

Be sure to have the units mounted on stands above the highest average snowfall. Having snow pile up or water from defrost freeze in the pans or on the bottom of the coils can be very problematic. Be sure the bottom of the units are clean, as that can also cause the water not to drain out of the pan.

—Ryan

P.S. – Here is a good flare gauge available from TruTech Tools

Comments

To leave a comment, you need to log in.

Log In