How to Test Heat Pump Defrost and How Defrost Works

January 14, 2019

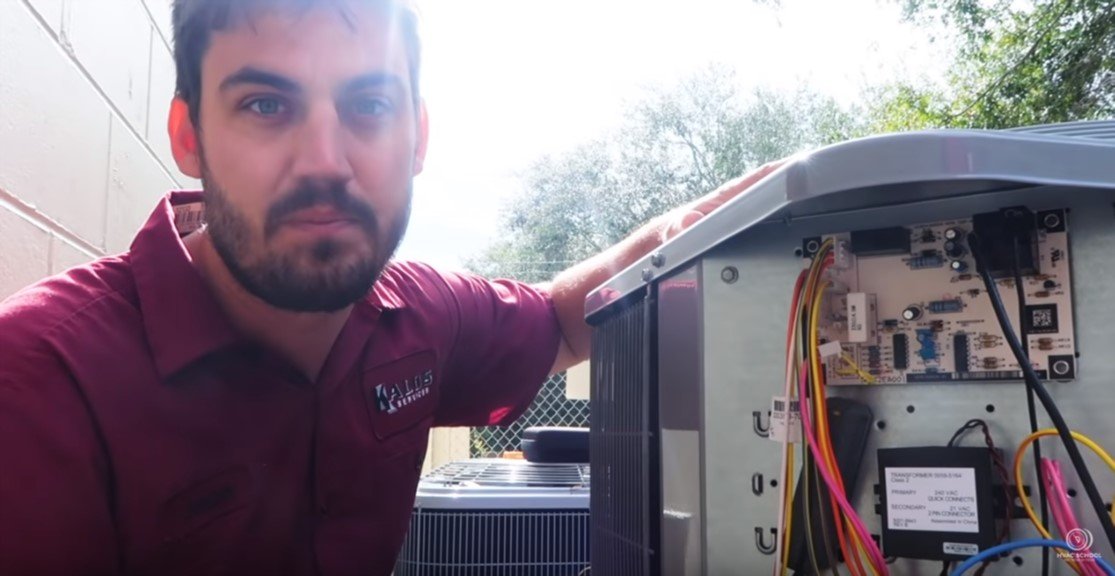

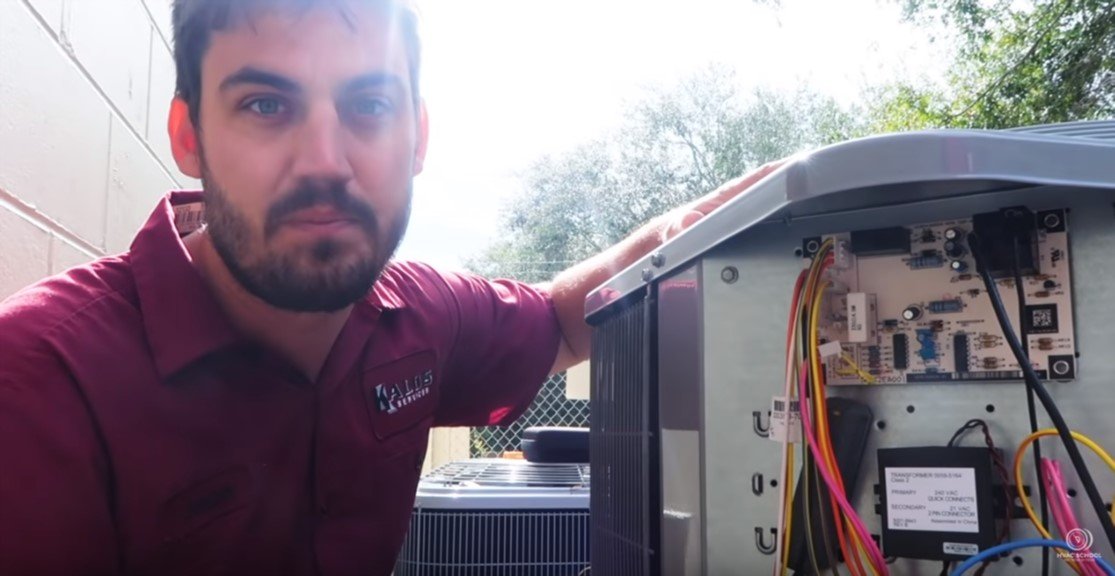

On a Carrier heat pump, the outdoor fan motor connects to the outdoor fan relay underneath the panel. Carrier heat pumps also have a defrost or coil sensor that connects to the defrost board (via a pink wire in this case); that sensor picks up the coil temperature and tells it to the board so that the board knows when to go into defrost. When the system goes into defrost, a 24v signal goes to the reversing valve to switch the cycle from heating to cooling, the outdoor fan motor shuts off, and a 24v signal goes out on the white wire to bring on the backup heat indoors. There is also a setting on the board that allows you to set timed defrosts for specific intervals. This Carrier system also has a speed-up tap to allow you to speed up the testing cycle.

Forcing the heat pump into cooling mode for defrost ensures that hot discharge gas goes to the outdoor coil. Since we don’t want the space temperature to drop too much, the heat strips are forced on indoors.

The Carrier defrost board differs from the Trane defrost board in that the Trane defrost board has two temperature sensors (coil AND ambient). There are three test pins in a Trane system, and the Trane will stop the defrost cycle by itself when it determines that the temperature is well above freezing. (The Carrier system can terminate defrost after 10 minutes OR when the defrost thermostat opens around 65 degrees, whichever one comes first.)

Trane defrost boards don’t have adjustable 30, 60, or 90-minute settings (which tell the defrost board when to check the sensor); they terminate defrost based on the sensor at all times and have average defrost times of around 6 minutes.

On a Trane system, you can check the charge in heating mode a bit differently than on a Carrier system. The locations of the ports and metering device are different on Trane systems than on Carrier systems; Carrier systems have a piston right before the liquid line service valve, so you must use your common suction pressure and discharge pressure to check the charge. Trane systems give you access to subcooled liquid before the metering device, as the TXV is inside the condensing unit.

Both Trane and Carrier systems have their reversing valves energized in cooling mode. In general, Ruud and Rheem tend to be the two main manufacturers that have their reversing valves energized in heating mode. However, the defrost process itself tends to stay consistent across most manufacturers’ equipment (how the boards read, when the condensing fan drops out, etc.). The process of locating data is also quite similar across most manufacturers’ equipment; you need to consult their charts in cooling and heating mode, which should be available in the manufacturer’s literature.

Carrier’s pistons can seat or unseat themselves to allow or block the flow of refrigerant, but some Trane systems generally have check valves that allow the refrigerant to bypass metering devices that are not in use. Nowadays, newer Trane systems have TXVs that permit refrigerant to bypass the metering device that is not in use.

Comments

This was a great video for learning about defrost boards

This was a great video for learning about defrost boards

To leave a comment, you need to log in.

Log In