How to Evacuate an AC system, Full Vacuum Procedure

November 26, 2019

This video is a collaboration with Paul from The Engineering Mindset channel. Check out Paul’s video on how a vacuum pump works here: https://www.youtube.com/watch?v=pnqXEnn3DNk&feature=youtu.be

The goal of a deep vacuum is to get EVERYTHING out of the system, including non-condensable gases, oxygen, water vapor, and other contaminants in the air. There isn’t really such a thing as a true “vacuum,” which is the absence of molecules; however, the vacuum pump creates negative pressure, which forces molecules to move towards the area of lower pressure. We measure vacuum in tiny units called microns; one micron is equivalent to one-MILLIONTH of a meter of mercury column. Atmospheric pressure is equivalent to 762,000 microns, and the vacuum pump should pull below 500 microns.

Before we even hook up a vacuum pump, we need to make sure we have a clean, dry, and tight system that’s free of solid and liquid contaminants. To do that, make sure your copper is sealed and that you are purging with nitrogen and flowing it while brazing. The system also needs to be leak-free before you connect the vacuum pump, and you can verify that a system is leak-free with a pressure test and a bubble test at joints. Eventually, the decay test will reveal microscopic leaks, which is normal.

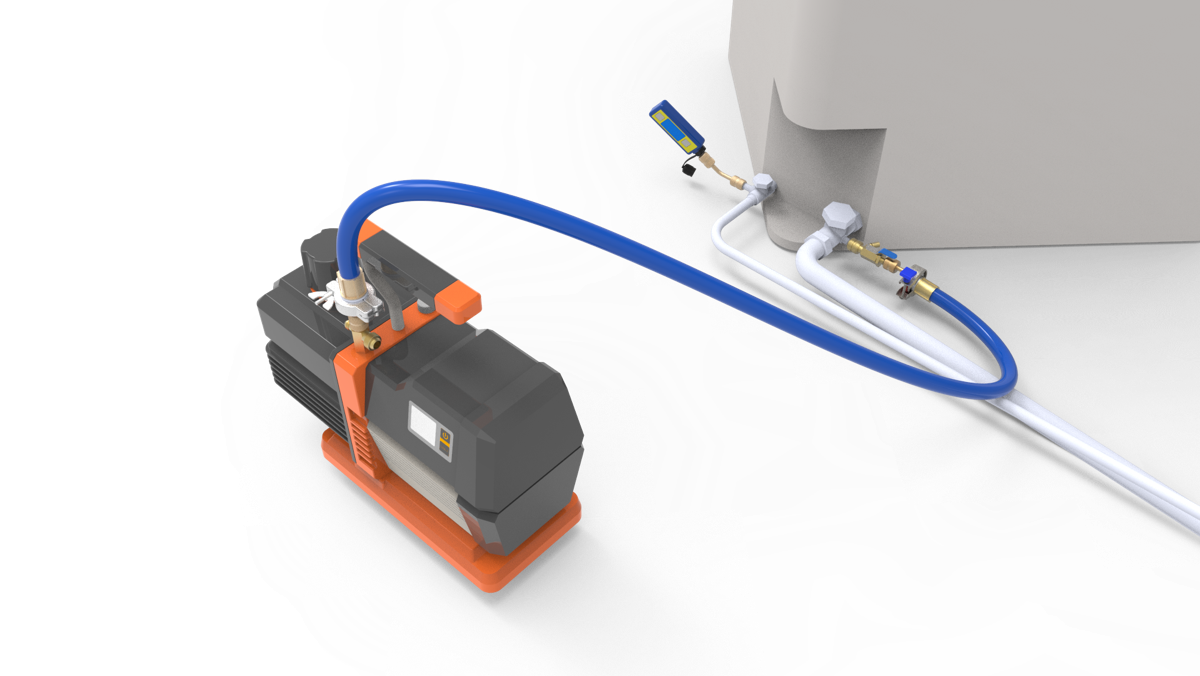

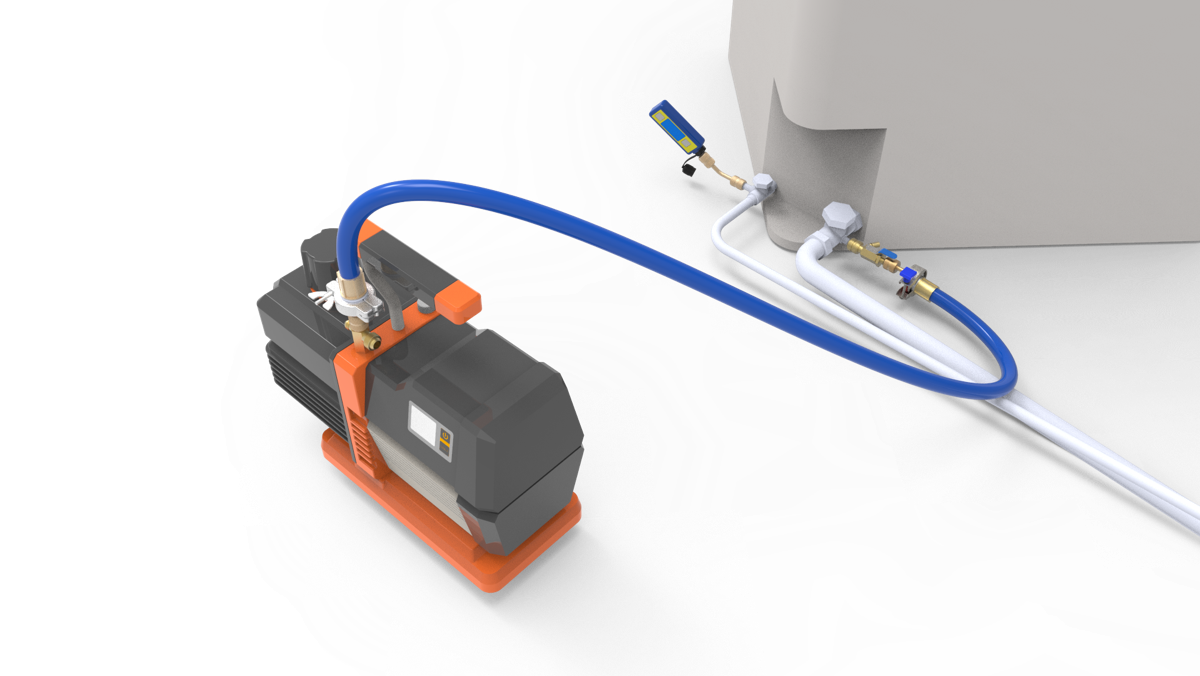

For best results, use a modern two-stage vacuum pump, large-diameter vacuum hoses (greater than 1/4″ and not a manifold or refrigerant hose), a core remover tool, and a high-quality vacuum gauge that reads in the micron scale. You also need to check the vacuum pump oil level and quality; change the oil if it’s opaque or the level is low. Then, connect the micron gauge to the pump and pull below 50 microns to confirm that the pump is working. It’s also a good idea to utilize the gas ballast when you’re working on a potentially wet system. A system that’s known to have water in it can benefit from the use of a heat gun to speed up the boiling process under low pressure.

To connect to the system, make sure there’s no pressure on the system. Use the core removal tools to remove the cores from the system. From there, you can use a one-hose setup or two-hose setup to attach the pump. If you’re pulling a vacuum on the evaporator and line set, a one-hose setup will suffice. However, a two-hose setup is ideal if you’re pulling a vacuum on the entire system. After you remove the core from the side you’re pulling the vacuum from, remove the end of the tool and connect the hose. Connect the hose back to the vacuum pump and attach your micron gauge to the system (as far away from the pump as possible); you can use a brass adapter with a core depressor to attach the micron gauge.

Then, you pull the system below 500 microns and isolate the system by shutting off the core remover tool. You will then do your decay test, where you make sure the system pressure doesn’t rise. In general, pulling below 500 microns, isolating for 10 minutes, and making sure the pressure doesn’t rise above 1000 microns will suffice; we pull below 300 microns and make sure the pressure doesn’t exceed 500 microns in 10 minutes. However, the sensor in the micron gauge can be affected by refrigerant and can give strange numbers. (You can break the vacuum with nitrogen to stop that.)

There are some myths about pulling fast, deep vacuums. One myth is that you’ll freeze water in the system, and the other is that you’ll damage the oil by pulling too deep. POE oil actually requires a very deep vacuum, and you won’t damage the oil unless you pull below 1 micron. You CAN freeze water in a vacuum, but there is usually enough heat in the HVAC system to prevent that from happening.

Comments

To leave a comment, you need to log in.

Log In