Cleaning a Grocery Case

September 3, 2019

When cleaning a case, the first thing the techs do is expose the fans and the coils by removing the product shelving. Then, they fill a bucket, the CoilJet, and the dry steam cleaner with water to prepare for cleaning.

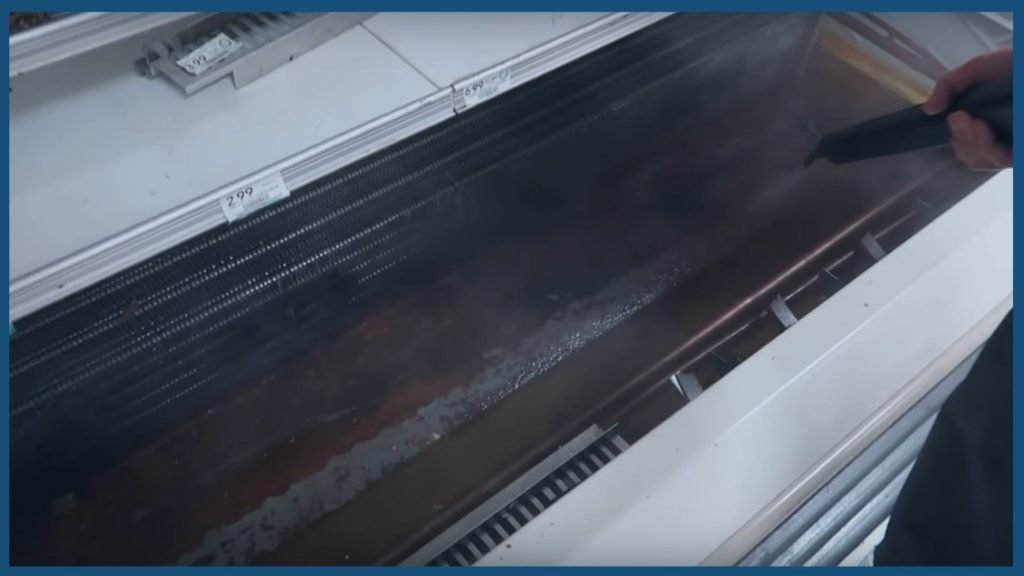

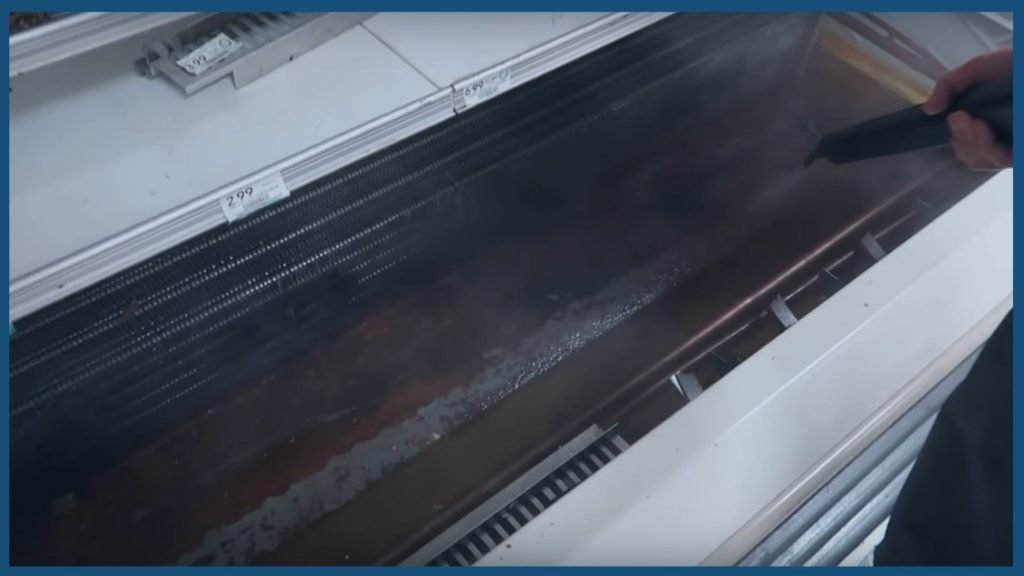

Bryan then flushes the case and uses the dry steam to sanitize the coil. He uses the CoilJet to clean out some of the sludge from the area beneath the coil. After the initial rinse, Bryan applies some food-safe cleaner (Viper EVAP+, which is labeled as “safe for food processing areas”) and lets it dwell to sanitize the coil. Since the cleaner is a food-safe sanitizer, Bryan applies it in the heaviest concentration.

Once the cleaner has had some time to sit for a while, the techs wipe it away and finish off with an application of Viper Pan & Drain Treatment from Refrigeration Technologies, which tends to outperform pan tabs and can be applied to the bottom row of the coil.

With the Viper Pan & Drain Treatment applied, the Kalos techs reassemble the grocery case. With the grocery case cleaned and fully assembled, the Kalos team closes out the job by confirming the equipment operation.

Learn more about SpeedClean at https://www.speedclean.com/.

Check out Refrigeration Technologies products at https://www.refrigtech.com/.

Comments

To leave a comment, you need to log in.

Log In