Get Tech Tips

Subscribe to free tech tips.

The Ductless Dehumidification Conundrum

This tech tip was a COMMENT on a Facebook question about how ductless systems achieve some of their high-efficiency numbers at the expense of dehumidification.

This was the question:

Bryan Orr mentioned that multi-stage mini splits often do very little latent cooling (dehumidification) because on low speed the manufacturers all “let the evaporator float, which makes it much warmer.” Can someone explain that? What does it mean to let the evaporator “float?” What's the alternative?

I was pointing out that colder evaporator coils and longer run times equal better dehumidification. Ductless systems often ramp down the compressor (lower RPM) as the indoor temperature approaches the setpoint, resulting in a warmer evaporator and poor dehumidification. My solution to this is a dehumidification mode in ductless systems that keeps a colder evaporator at the expense of lower efficiency when it is needed.

All of this is a trade-off between a colder evaporator being better for dehumidification and a warmer evaporator/lower compression ratio being better for efficiency.

One of my friends is a tech named Joel Becker, who happens to be an insanely smart and detailed guy. He tackled the question with so much detail that I asked if I could make it a tech tip. He agreed, and here is his comment, which I find to be spot on. Enjoy.

Evaporator coils do two things to refrigerant: First, all the refrigerant boils to a vapor, and then it gets superheated (heated above boiling).

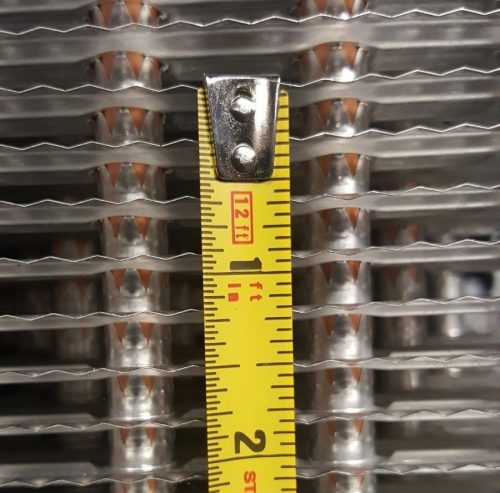

Evaporator coils also do two things to what we call “air,” which is actually a gas-vapor mixture that includes water vapor. The coil removes sensible heat from the air (lowers the temperature) and also changes the phase of water vapor from the air to liquid. To state this in simple terms, it cools and dehumidifies. As the temperature of the coil drops, the difference between the surface temperature of the evaporator coil and the dew point of the air through the coil increases, and more water vapor from the air condenses on the coil. This “latent” heat removal takes away from the “sensible” capacity of the system to cool air. In A/C system expanded performance specifications, the “sensible ratio” shows how much heat will be used for each of these separate functions under various outdoor air temperature conditions, indoor air temperature, indoor air humidity, and evaporator airflow rates.

The refrigerant enters the coil at a rate controlled by a metering device, and its pressure is controlled so that its boiling point is below the temperature of the air. If we reduce the refrigerant flow into the coil by closing the metering device but keep everything else the same, then the compressor suction will pull the pressure of the coil down lower. This results in a lower boiling point for the refrigerant entering the coil and a lower surface temperature of the “active” portion of the coil. However, the coil is now “oversized,” so we're not using much of it to boil refrigerant; the majority of the coil is now being used to superheat the vapor refrigerant after it has completely boiled off. At this point, if dehumidification is the priority, we can slow airflow down enough to reduce the superheat and keep a greater portion of the coil colder. Again, the goal is to have a large surface area that is significantly lower than the dew point of the air (without dropping below 0°C/32°F). This all results in a big difference in pressure between the discharge and suction gas at the compressor (compression ratio.)

Since the priorities of regulators and consumers seem to be exclusively revolving around high efficiency, manufacturers respond by creating products that have a super high SEER/EER. Low compression ratios are mainly how these high ratings are achieved. Equipment is designed with large coils outside to transfer more heat and boil more refrigerant with the refrigerant condensing at a lower pressure and temperature, and larger coils indoors where the refrigerant is boiled off, starting from a higher pressure and temperature. Especially in “VRF” systems, including residential mini-splits where all the fans are variable, the refrigerant metering to the indoor coil is variable, and the compressor speed is variable. The SEER rating gets sky-high because of how they behave with a call for cooling under low load conditions. The outdoor coil pressure (compressor discharge pressure) is maintained just high enough for a small volume of refrigerant to condense, and the evaporator coil pressure (compressor suction pressure) is maintained so that refrigerant boils off at a temperature just lower than the air entering the coil. This rise in evaporator (suction) pressure is what Bryan is referring to as “floating.” This all works great in Arizona, but if you still need some dehumidification, you're kinda out of luck. No part of the evaporator coil surface area is at a temperature far enough below the dew point of the entering air to condense any water vapor from the air; the system operates very efficiently at a sensible ratio of 1.

There are a few different ways to fix this. The most economical, I would think, would be to set the equipment up with a “dry mode” that keeps the compressor speed/compression ratio up, the coil/suction pressure/refrigerant saturation temperature aka boiling point, and indoor fan speed low, but turn the fan up as needed to maintain temperature set point. The regular “cool mode” could stay the same as it is now, so their sky-high SEER rating wouldn't be affected. This is not how the typical “dry mode” works on most mini-split systems. Daikin has a system with a subcooling coil inside that provides reheat. It can maintain a narrow temperature and humidity range, but that's expensive, and I think it's usually unnecessary.

The other issue that comes into play often, at least in my experience in the residential market, is that 9000 BTUs/hr or 3/4 ton is still the smallest 1:1 system available, which was the right size for a fairly small room in the 90s. Under current codes, it is the right size for typically a very large area. We often install a 9K system in a room where the load is 2500-5000 BTUs/hr, so these will always run way below full speed and usually do absolutely no dehumidification. Again, fancy and expensive dehumidification features like the subcooling coil in the Daikin probably wouldn't be necessary for some applications if we could just get a system that was sized closer to the load.

—Joel Becker

P.S. – If you want to learn more about reducing indoor humidity in general, you can check out this HVAC School article.

Comments

I am a builder of energy efficient homes that generally have a blower door test of .5 ACH50 or below. Coastal NC is extremely humid, so this topic is of great concern to us. Accepted practice in all of my homes is to install a dedicated ducted dehumidifier independent of the HVAC system. Research that I have followed support this approach as the most effective. The rationale is based upon several factors. 1) an extremely tight home has humidity to remove even during winter months. 2) we have four months were little heat or AC is used. 3) as we build tighter more efficient homes, the sensible load is diminished along with the latent capability of HVAC system. All of these are solved with a dedicated dehumidification system. As our attics and crawl spaces are all insulated and sealed along with the living spaces, we install and Aprilaire 70 pint system in the attic along with powered makeup air being added to that space for mixing prior to entering the living spaces. Humidity is set for 45% year-round and that is achieved with remarkable consistency.

I am a builder of energy efficient homes that generally have a blower door test of .5 ACH50 or below. Coastal NC is extremely humid, so this topic is of great concern to us. Accepted practice in all of my homes is to install a dedicated ducted dehumidifier independent of the HVAC system. Research that I have followed support this approach as the most effective. The rationale is based upon several factors. 1) an extremely tight home has humidity to remove even during winter months. 2) we have four months were little heat or AC is used. 3) as we build tighter more efficient homes, the sensible load is diminished along with the latent capability of HVAC system. All of these are solved with a dedicated dehumidification system. As our attics and crawl spaces are all insulated and sealed along with the living spaces, we install and Aprilaire 70 pint system in the attic along with powered makeup air being added to that space for mixing prior to entering the living spaces. Humidity is set for 45% year-round and that is achieved with remarkable consistency.

https://kamagraprix.com/# achat kamagra

https://kamagraprix.com/# achat kamagra

Kamagra Oral Jelly pas cher acheter kamagra site fiable or kamagra pas cher

http://penza-job.ru/phpinfo.php?a%5B%5D=Generic Viagra online achat kamagra

[url=https://images.google.ci/url?q=https://kamagraprix.shop]achat kamagra[/url] kamagra gel and [url=http://jiangzhongyou.net/space-uid-594447.html]achat kamagra[/url] Acheter Kamagra site fiable

Kamagra Oral Jelly pas cher acheter kamagra site fiable or kamagra pas cher

http://penza-job.ru/phpinfo.php?a%5B%5D=Generic Viagra online achat kamagra

[url=https://images.google.ci/url?q=https://kamagraprix.shop]achat kamagra[/url] kamagra gel and [url=http://jiangzhongyou.net/space-uid-594447.html]achat kamagra[/url] Acheter Kamagra site fiable

kamagra gel Achetez vos kamagra medicaments or kamagra gel

https://cse.google.co.zw/url?q=https://kamagraprix.com kamagra pas cher

[url=https://www.google.com.nf/url?q=https://kamagraprix.com]Achetez vos kamagra medicaments[/url] kamagra en ligne and [url=http://www.donggoudi.com/home.php?mod=space&uid=2822320]kamagra gel[/url] Achetez vos kamagra medicaments

kamagra gel Achetez vos kamagra medicaments or kamagra gel

https://cse.google.co.zw/url?q=https://kamagraprix.com kamagra pas cher

[url=https://www.google.com.nf/url?q=https://kamagraprix.com]Achetez vos kamagra medicaments[/url] kamagra en ligne and [url=http://www.donggoudi.com/home.php?mod=space&uid=2822320]kamagra gel[/url] Achetez vos kamagra medicaments

cialis sans ordonnance [url=http://tadalmed.com/#]Acheter Cialis 20 mg pas cher[/url] Tadalafil sans ordonnance en ligne tadalmed.com

cialis sans ordonnance [url=http://tadalmed.com/#]Acheter Cialis 20 mg pas cher[/url] Tadalafil sans ordonnance en ligne tadalmed.com

https://tadalmed.shop/# cialis generique

https://tadalmed.shop/# cialis generique

Pharmacie sans ordonnance Pharmacie sans ordonnance or Pharmacie Internationale en ligne

https://maps.google.pn/url?q=https://pharmafst.com Pharmacie en ligne livraison Europe

[url=https://maps.google.se/url?sa=t&url=https://pharmafst.com]pharmacie en ligne france livraison belgique[/url] pharmacie en ligne fiable and [url=https://jutianwang.cn/home.php?mod=space&uid=21919&do=profile&from=space]pharmacies en ligne certifiГ©es[/url] Pharmacie en ligne livraison Europe

Pharmacie sans ordonnance Pharmacie sans ordonnance or Pharmacie Internationale en ligne

https://maps.google.pn/url?q=https://pharmafst.com Pharmacie en ligne livraison Europe

[url=https://maps.google.se/url?sa=t&url=https://pharmafst.com]pharmacie en ligne france livraison belgique[/url] pharmacie en ligne fiable and [url=https://jutianwang.cn/home.php?mod=space&uid=21919&do=profile&from=space]pharmacies en ligne certifiГ©es[/url] Pharmacie en ligne livraison Europe

olympe casino en ligne: olympe casino – olympe casino cresus

olympe casino en ligne: olympe casino – olympe casino cresus

In the response/answer there is no mention of the fan setting having an affect on dehumidification. Typically I set M/S’s to AUTO, but they may be on L/M or High when I check them. Is there any difference in relation to dehumidification? I’m in Northeast Florida. Thank you.

In the response/answer there is no mention of the fan setting having an affect on dehumidification. Typically I set M/S’s to AUTO, but they may be on L/M or High when I check them. Is there any difference in relation to dehumidification? I’m in Northeast Florida. Thank you.

I presume the EER and SEER ratings include both the sensible and latent heat removed, simply that the manufacturer has no incentive to prioritize latent heat removal when aiming for a high SEER.

If I had a magical machine that removed 12000 BTU/hr of latent heat only, with no air temperature change, using 1 kW of electrical energy input, that would still ‘count’ as an EER of 12, correct?

-Jon

I presume the EER and SEER ratings include both the sensible and latent heat removed, simply that the manufacturer has no incentive to prioritize latent heat removal when aiming for a high SEER.

If I had a magical machine that removed 12000 BTU/hr of latent heat only, with no air temperature change, using 1 kW of electrical energy input, that would still ‘count’ as an EER of 12, correct?

-Jon

Pharmacie sans ordonnance [url=http://pharmafst.com/#]pharmacie en ligne sans ordonnance[/url] pharmacie en ligne sans ordonnance pharmafst.shop

Pharmacie sans ordonnance [url=http://pharmafst.com/#]pharmacie en ligne sans ordonnance[/url] pharmacie en ligne sans ordonnance pharmafst.shop

To leave a comment, you need to log in.

Log In