Get Tech Tips

Subscribe to free tech tips.

Testing the Leak Rate on Your Micron Gauge Itself

As a technician gains skill, they will learn that regularly testing your tools is a huge part of success. It isn't long in the field before techs find out that just because a meter or gauge gives a particular reading, it doesn't ALWAYS mean it is correct. Vacuum is one of these areas.

Everything in an air conditioning and refrigeration system leaks to some extent, so our job isn't to eliminate all leaks. Our job is to reduce the leakage rate to as low as possible. When using a sensitive micron gauge, we find that isolating an assembly and checking the “decay” or standing leak rate is a great way to test and ensure that a system has minimal leaks and moisture. The challenge is that all of the connections in your rig leak, and even the vacuum gauge itself leaks.

Some techs attempt to test the leak rate on their micron gauge by connecting it to a core tool and then straight to the pump, evacuating the gauge down to a very low level, and then valving off. If you do this, you will find that every commercially available vacuum (micron) gauge shoots up pretty quickly. That is because the VOLUME of the gauge and coupler are so low that ANY leakage whatsoever has an enormous effect.

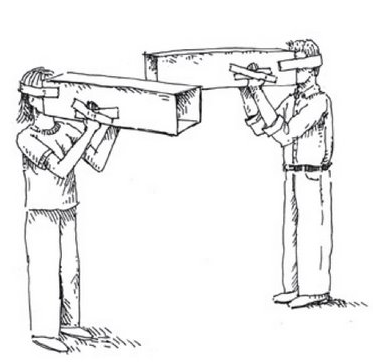

In this video, Ulises Palacios shows us how to use an empty recovery tank to test the leak rate of a vacuum gauge rig accurately.

It is certainly important to test all of your vacuum rig components. Just remember that volume makes a huge difference when decay (standing vacuum) leak testing.

—Bryan

Comments

To leave a comment, you need to log in.

Log In