BACK

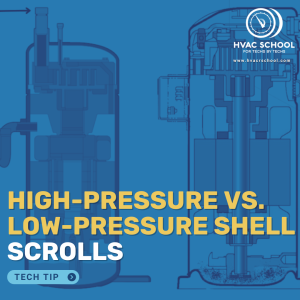

High-Pressure vs. Low-Pressure Shell Scrolls: A Deeper Dive

High-Pressure vs. Low-Pressure Shell Scrolls: A Deeper Dive

How Do Communicating Systems Work?

How Do Communicating Systems Work?

VRV Operation

VRV Operation

VRV/VRF Installation Tips

VRV/VRF Installation Tips

VRV Basics

VRV Basics

Why VRF Compressors Die w/ Roman

Why VRF Compressors Die w/ Roman

Roman SpeakPipe VRF – Short #235

Roman SpeakPipe VRF – Short #235

VRF Tech Talk Takeover Podcast

VRF Tech Talk Takeover Podcast

So You Want to Service VRF?

So You Want to Service VRF?

#VRV

Tech Tips:

I want to share something that came up in a recent discussion with Roman Baugh about VRF systems, and it made me realize I might have had a blind spot regarding scroll compressor designs. We were talking specifics, and he brought up high-pressure shell compressors. My immediate thought was, “Hold on, aren't scrolls low-pressure shell […]

Read more

This tech tip recaps the livestream by the same name, featuring HVAC School contributors Matt Bruner and Adam Mufich, as well as special guest Steve Cook from Hisense. You can watch that livestream on our YouTube channel HERE. We also owe special thanks to Roman Baugh, who added some extra information on the topic. Communicating […]

Read more

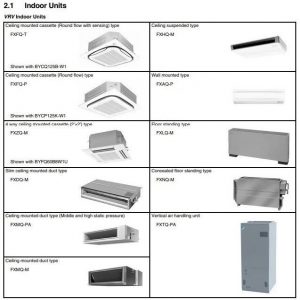

This tech tip is written by experienced tech and VRF / VRV specialist Ryan Findley. Thanks, Ryan! (Note: Ryan refers to VRV rather than VRF because he specializes in Daikin, and these articles are written from a Daikin VRV perspective. Ryan has also written an article about VRV basics and some VRV installation tips.) This […]

Read more

This tech tip was written by experienced tech and VRF/VRV specialist Ryan Findley. Thanks, Ryan! (Note: Ryan refers to VRV rather than VRF because he specializes in Daikin, and these articles are written from a Daikin VRV perspective. He also wrote a great introductory guide to VRV systems, which you can find here.) In this […]

Read more

This tech tip was written by experienced tech and VRV specialist Ryan Findley. Thanks, Ryan. This is a quick overview, not a substitute for taking proper manufacturer training. This tech tip is geared towards the mechanic who is fairly new to VRV systems. As with anything, before we harness the ability to install or […]

Read moreVideos:

Podcasts:

In this episode, Bryan and Roman dive deep into the world of Variable Refrigerant Flow (VRF) systems, focusing on the persistent issue of compressor failures. VRF technology has evolved, and it has seen a major rise in the North American market since the early 2010s. Roman shares his passion for VRF, tracing its origins […]

Read more

In this short podcast episode, Roman Baugh takes over the HVAC School podcast to answer a listener-submitted question about VRF (or VRV) system evacuation. Evacuation is a critical step of making repairs on VRF systems, which are very diverse and versatile but require a high level of understanding. VRF systems have multiple indoor units […]

Read more

Roman Baugh and Donald Falese from VRF Tech Talk podcast takeover the HVAC School booth at AHR EXPO 2025. Join them as they talk about the new VRF products being unveiled, water-cooled VRF ups and downs, and why VRF is such a difficult trade to work in. You will not want to miss this […]

Read moreEvents:

NOTE: If you cannot view the recording, the video may still be processing. The maximum wait time is 24 hours. We apologize for the delay and appreciate your patience.

Read more