BACK

Replacing an Evaporator Coil

Replacing an Evaporator Coil

What is a HSO (Non-Bleed) TXV/TEV?

What is a HSO (Non-Bleed) TXV/TEV?

Should I Pump Down or Recover?

Should I Pump Down or Recover?

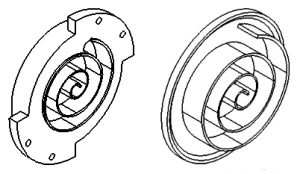

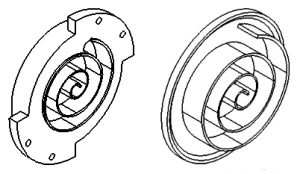

Scroll Compressor Pump Down, Megohm Test & Fusite Terminals

Scroll Compressor Pump Down, Megohm Test & Fusite Terminals

Refrigeration Pump-down Cycle

Refrigeration Pump-down Cycle

Changing Liquid Filter/Drier Cores Tip

Changing Liquid Filter/Drier Cores Tip

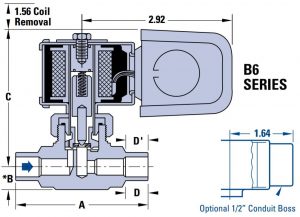

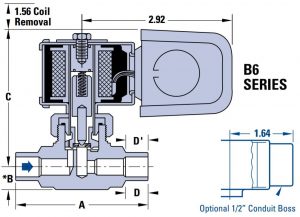

Solenoid Facts

Solenoid Facts

Preventing Slugging & Flooding w/ Copeland

Preventing Slugging & Flooding w/ Copeland

#pump down

Tech Tips:

Evaporator coil leaks are a fact of life in the industry. (We could have a long and lively discussion about how evap coils aren’t made like they used to be, but that’s for another day.) When you have an evaporator leak on a system, you’ll have two choices to fix the problem: replace the coil […]

Read more

There is a lot of misunderstanding about the HSO (hard shut-off) or “non-bleed” TXV (thermostat expansion valve) and what makes it shut off, why it exists, and how it “magically” opens. Once you understand the forces inside the valve, it is quite simple, obvious, and sadly devoid of any magic. The Three Forces The TXV […]

Read more

During my second year in HVAC, the company I worked for was hired to fix some poor work that was done on a multi-head inverter system. The system used flare connections, and many of them were leaking. The system also had a branch box, which meant there were even MORE flares. So we pumped all […]

Read more

This tip will be like an episode of Columbo; we will start with the what and who and then get to the why. Don't pump down a scroll into a vacuum. Don't run a scroll in a vacuum. Don't run a high voltage megohmmeter or Hi-pot test on a scroll (As a general rule, don't […]

Read more

This article was written by Jeremy Smith CM, an experienced refrigeration tech and all-around great dude. Thanks, Jeremy. A very common means of control seen on refrigeration equipment is the pump down control. Why do we use this rather than just cycling the compressor off and on like a residential HVAC unit? Since most refrigeration equipment […]

Read more

This tip comes from market refrigeration and controls technician Kevin Compass. Thanks, Kevin! A little tip when changing liquid cores: If you start pumping them down, begin bypassing discharge gas into the shell to warm it up, push out the remaining liquid, and bring the shell above the dew point so that it doesn't sweat […]

Read more

Do you know how a solenoid valve works? Really? On the surface, I think we all understand how a solenoid valve works. The coil energizes, creating an electromagnet. That temporary magnetism lifts an iron plunger within the valve allowing refrigerant to flow. But is it really that simple? It turns out that the answer isn't […]

Read more

Podcasts:

In this episode of the HVAC School Podcast, host Bryan welcomes Jeff from Copeland to discuss the critical topic of flooding and slugging in compressors. Jeff, calling in from frigid Minnesota (at negative 19°F), explains the differences between these harmful conditions and how they can damage compressor systems. The conversation begins by differentiating between […]

Read more