Get Tech Tips

Subscribe to free tech tips.

Surge Protector Facts

How do HVAC surge protectors work? What sorts of electrical events do they protect HVAC systems from? Does every HVAC system need one? What is undervoltage protection? In this article, we will cover the basics of surge protection and help you determine the best use cases for the various options available in residential applications.

The Problem

HVAC surge protectors are part of a larger class of devices that are designed to extend the life of sensitive electronics. When semiconductors became common in the 1970s, it became apparent that these components were more sensitive to overvoltage than other types of electric components. For us in the HVAC world, this means main control boards, inverter boards and ECM motor modules to name a few.

Oftentimes, we think about surge protectors as insurance against a singular destructive event, such as a lightning strike. But there is a case to be made that periodic overvoltage can decrease the lifespan of electronics with semiconductors.

In one of its articles on surge damage, the National Electrical Manufacturers Association says,

The average person, unless taught otherwise, often believes that surge damage is a one-time event. When lightning strikes and a piece of equipment is damaged, the damage may be attributed to a transient impulse. But when a piece of equipment fails due to the accumulation of numerous smaller magnitude surges, the failure is attributed to the age of equipment, poor quality of the equipment, or a hundred other unexplained conditions.

The 2020 National Electrical Code requires whole home surge protection. Voltage spikes can be caused by weather events but are more commonly caused by issues related to the power grid and happen frequently.

How Surge Protection Works

Ideally, the incoming power from the grid would be a nice smooth sine wave. In reality, this is never the case, so small fluctuations are designed to be handled by the electronics. Larger fluctuations are too much to handle, though, and end up shortening their lifespan. The picture below shows voltage spikes and transients, which are above the rated voltage that an electrical component is designed to handle.

Surge protectors (sometimes also called surge arrestors) are made to “shunt” the extra voltage to ground. The surge protector will allow voltage to flow unimpeded until a certain level, which is called the clamping voltage. At this voltage, a metal oxide varistor—or MOV—begins diverting that extra voltage to ground or dissipating it as heat. There are other types of surge protectors, but most HVAC applications use MOVs. Because most surge protectors shunt extra voltage to ground, a really good ground connection is essential for these devices to work.

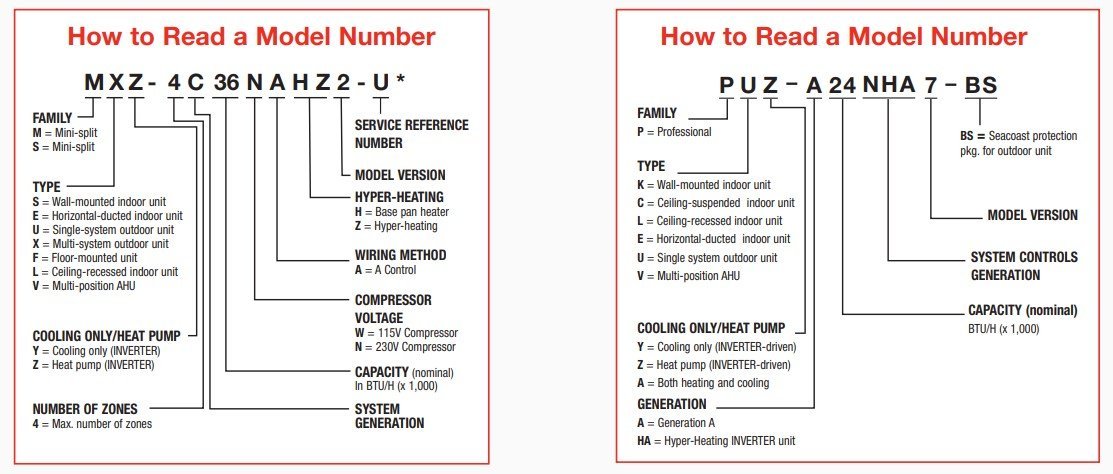

A surge protector should have its clamping voltage listed in the electrical specifications or in the product details. In the chart below, the clamping voltage for many of the surge protectors listed on the chart below is 130-150 volts. So anything below that voltage will be unimpeded by the surge protector.

From the Supco LBK10 informational PDF

Whether or not the surge protector will protect against lightning is dependent on its rating. There are 4 Types of surge protectors, Types 1 and 2 will protect against lightning (although probably not a direct strike on the home), and Types 3 and 4 will not. Types 1 and 2 are installed typically in the breaker box and provide whole-home surge protection. Many HVAC surge protectors are Type 3, point of use, and do not protect against lightning strikes.

Source: https://www.nemasurge.org/spd-location/

Other Types of Protection

What about other power quality issues, such as slight overvoltage, brownouts, or under voltage? The average surge protector does not protect against these issues, and additional protective devices will be needed if you are trying to find a solution to these problems.

Overvoltage

As noted above, the clamping voltage for these devices is typically well above the rated voltage for the unit. In the case of a typical condenser, the unit will have an allowable voltage range that is +/- 10% of 230 volts. So, if the clamping voltage is 130-150 volts per leg and we have a constant over-voltage situation that is just below the clamping voltage, we can have a problem. The max rated volts for the condenser below is 253, but the clamping voltage for the surge protector may not activate until 260, or possibly 300 volts.

Bryan has spoken about consistent overvoltage here, and the danger seems to be primarily for inverter systems. The solution is a device like the ICM 493, Kool Guard, or some other device that has the ability to cut power to the unit at a desired setting until the voltage drops back into a range allowable by the condenser. Here is a video of an ICM 493 installation if you’re interested in more information.

Undervoltage

The data plate above shows that the minimum voltage for the condenser is 197 volts. Anything less than that will cause damage to the equipment, primarily the compressor and fan motor. Electronics are not as negatively impacted by undervoltage. They may not work properly, but there is less of a chance of long-term damage. However, large loads like motors will generate more heat, draw higher amps, and fail more quickly. The solution to a problem like this is again something like the ICM 493 or Kool Guard, which disconnects power until the proper voltage is restored.

Brownouts

We also need to consider momentary brownouts (power flickers) and their effect on the equipment. In my area of the country, we have power flickers in the summer that will lock up a single-stage compressor and require the power to be reset on a communicating system. I’ve seen several cases where someone’s compressor overheated because they left the unit on; it would have fired right back up if they had shut it off. Many of the more advanced surge protective devices have a feature that disconnects the power when it senses a brownout. Another option is a SureSwitch from Emerson or another similar device, which can also sense brownouts and has a time delay of five minutes to protect the compressor.

However, there is a whole other side to this coin when talking about brownouts and inverter-driven equipment. Most inverter-driven equipment has internal sensors that detect temperature, electrical draw, and phase reversal. This type of equipment has the ability to shut itself down when voltage drops below the allowable threshold. This function prevents damage to the compressor and internal components. The same thing is true when it detects a continuous supply voltage that exceeds the normal threshold of allowable voltage (usually +/-10%).

Brownouts or lightning strikes cause irreparable damage to sensitive components like capacitors, communication transformers, and IGBTs built into the inverter board. The amount of damage usually depends on how long the brownout lasts and at what speed the system is running. Remember, when troubleshooting an inverter system after a board failure due to a brownout or voltage surge, it is important to test all components within the unit. The need for surge protectors on inverter-driven equipment is high. These surge protectors should be sized correctly based on the design of the system. Overall, the more communicating boards, capacitors, and sensitive components a unit has, the greater the need for a surge protector or electrical safety device.

Surge Protector Installation Considerations

I have often seen homeowners with whole-home surge protectors who ask if they need a separate surge protector on their air conditioner. Based on what we know about surge protectors, the answer would depend on a few things. A surge protector with a lower clamping voltage or the ability to disconnect the equipment may provide better protection. Having extra surge protection on valuable equipment may be worth it to a particular customer on such a valuable piece of equipment.

Another major consideration is the fact that many of these devices do not disconnect the equipment if the surge protector fails, as it likely will eventually. After that, the equipment is no longer protected.

As mentioned earlier, a good ground is essential for these devices to work at all, so verify that you have a good ground connection.

—Matt Bruner

Comments

To leave a comment, you need to log in.

Log In