Start Winding and Capacitor Crankcase Heater

August 17, 2018

Crankcase heat prevents liquid refrigerant from migrating to the compressor, which can lead to catastrophic failures. The traditional way of providing crankcase heat is with an insertion-type or belly-band crankcase heater that gets wired into the circuit. However, it’s possible to use the capacitor as a sort of crankcase heat.

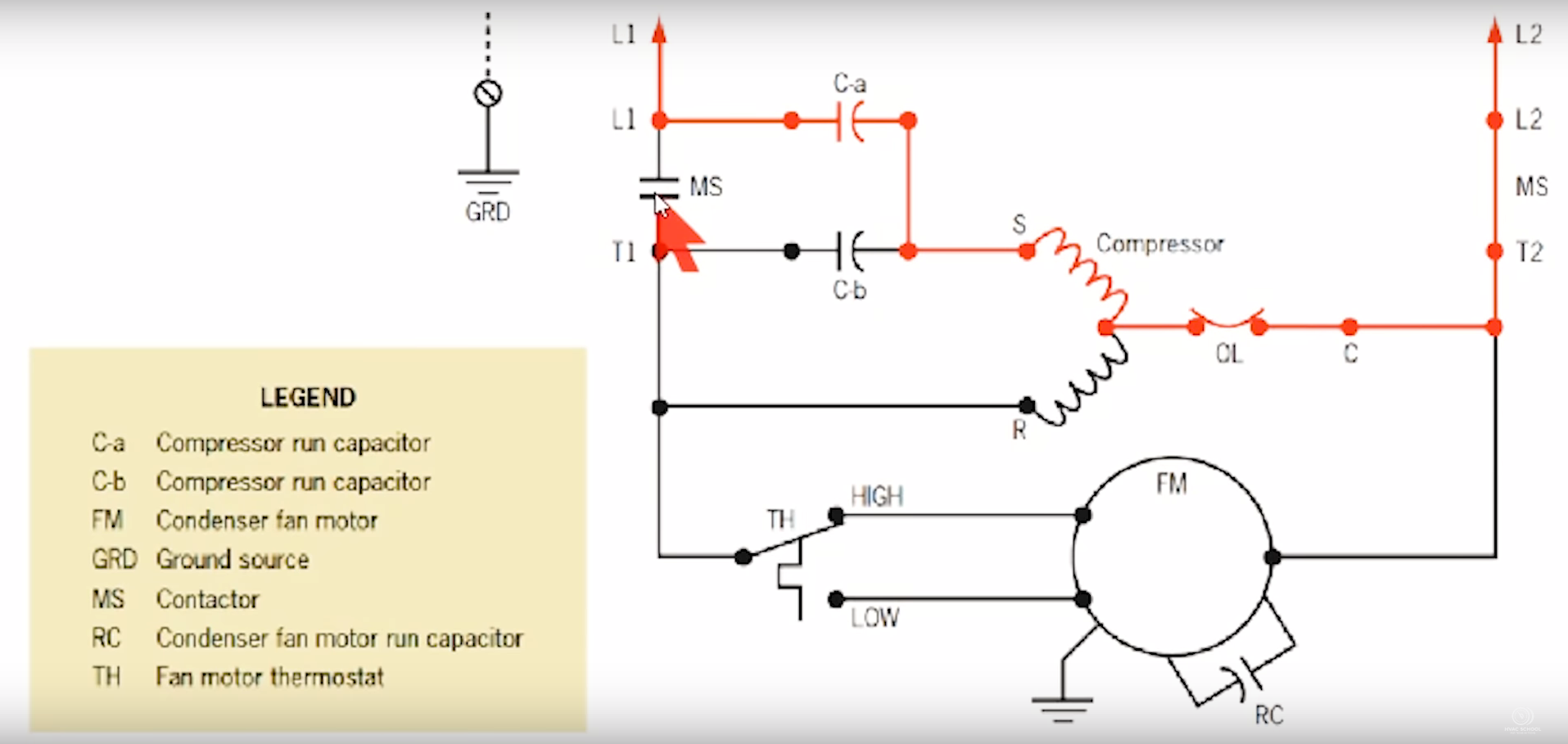

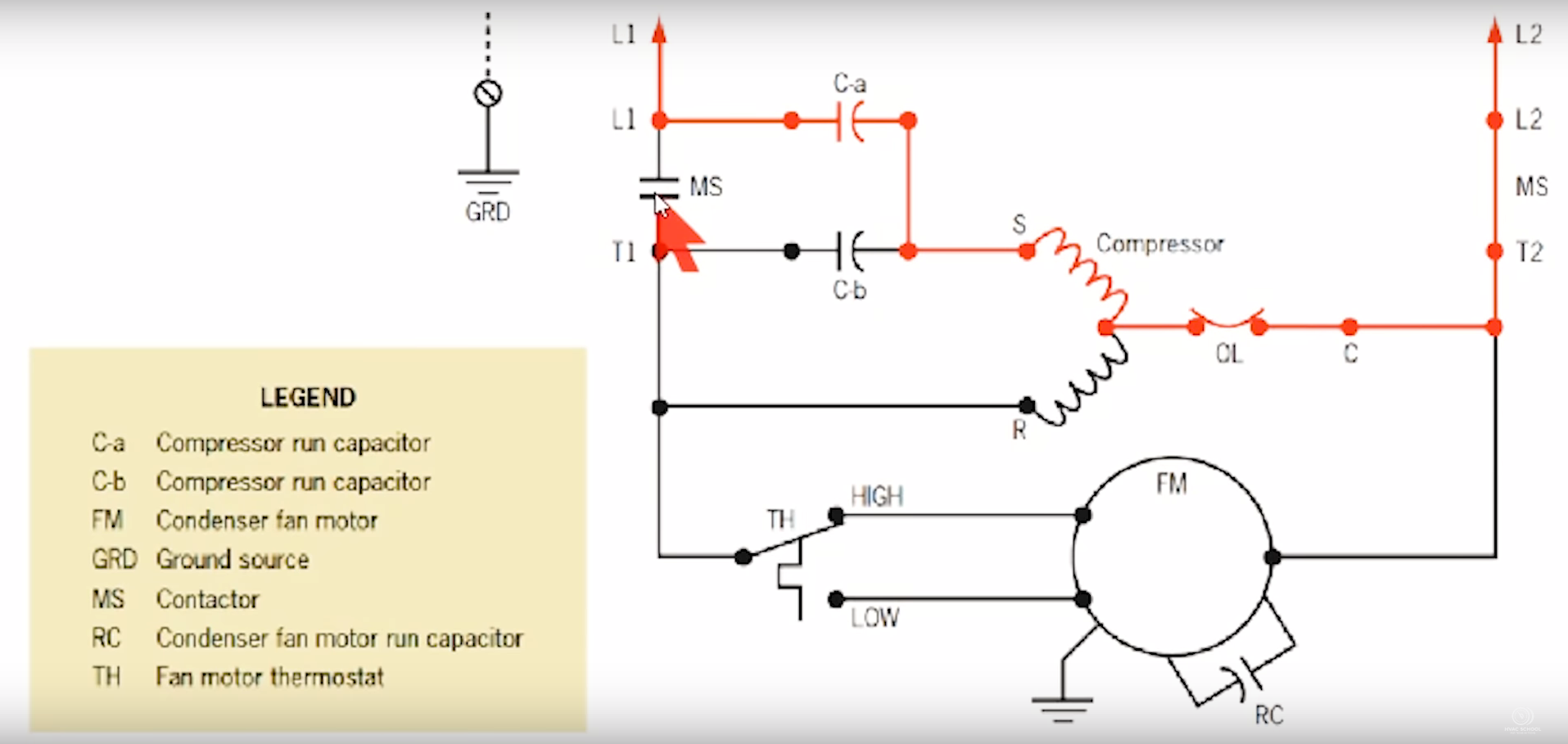

When two run capacitors are wired in parallel, you need to make sure they add up to the total microfarad capacity. One run capacitor (Ca) will have constant power coming in from L1; the other (Cb) is broken by the compressor contactor. That can sound a bit confusing, as Ca could only have a rating of 5 microfarads while Cb has 35. However, a capacitor charges and discharges at a given amperage at a given voltage, meaning that it allows a certain amount of electrons to flow through the circuit to the start winding.

When the compressor contact is open, the compressor doesn’t run, but Ca can then charge and discharge a small amount of current to the start winding, which acts as a source of crankcase heat. Closing the compressor contact allows Cb to come into the circuit, and the compressor runs as usual.

Comments

To leave a comment, you need to log in.

Log In