Get Tech Tips

Subscribe to free tech tips.

Some Furnace Questions

I received an email from a podcast listener with some furnace-related questions. Based on the nature of the questions, I figured it would be better to ask an experienced furnace tech. Benoît Mongeau agreed to help by answering the questions.

My name is Matt and I am a newer tech (fully licensed this September, have been doing the work for 2ish years) who lives in Northern Ontario, Canada. I really enjoy the HVACR school podcast. I don’t do any A/C stuff but I still enjoy listening and wrapping my brain around it. I have always struggled with the theory behind getting cold from hot. The bulk of my work is residential gas heating, mainly high-efficiency furnaces, and gas fireplaces. My questions for you are, (these are just ideas for your podcast though help is never turned down)

On a millivolt system (runs off of a thermopile)

– How to easily test for gas valve failure, what are the expected resistances across the solenoid in the gas valve?

– What expected readings should we consistently get from a properly working system (voltage of thermopile alone, with gas valve open, with thermostat closed etc)

On high efficiency

– What is the relationship between the pressures in the collector box of the secondary exchanger and the pressure switch?

– How does a clogged condensate trap lead to the pressure switch not closing?

Another Question

– Is it possible to check readings from the circuit board when the wires are in a harness? For example, I troubleshot a gas valve failure. It was either the board or the valve. The wires coming to the gas valve from the board are in a harness. How do I know which to check and what am I checking for. (Given that everything else was working I leaned toward a faulty gas valve and was right, just so you know!)

Thanks for your time and for doing the podcast.

All the best,

—Matt

For the collector box/pressure switch:

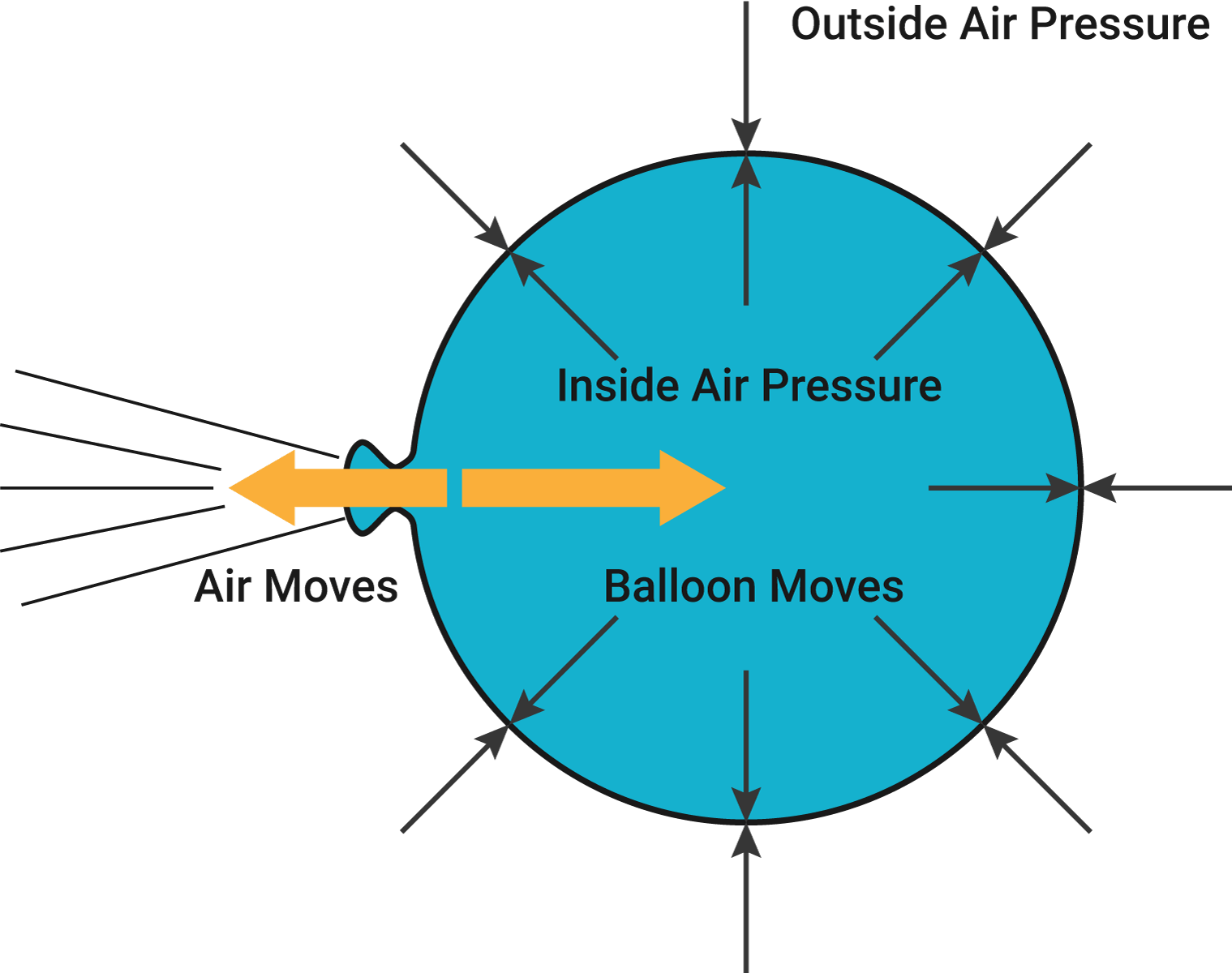

During normal operation, the collector box is under a vacuum (negative pressure) when the inducer is running. That vacuum is what the pressure switch checks for. If the vacuum is sufficient, the contacts will close and signal the board that everything is good. If your condensate trap is blocked, the collector box will still be under a vacuum. That doesn't change.

However, the pressure switch port (where the tube is attached to the collector box) should be at the bottom of the box, usually near the drain port. The backed-up condensate will simply end up blocking that port, and the switch will no longer be able to ”feel” the vacuum. The contacts won't make, and you will get an error (pressure switch not closing or stuck open).

What may also happen, but not always, is that the port will block during a cycle, and the vacuum will remain stuck in the pressure tube. As your inducer comes off and normal pressure returns, the air can't go in the pressure tubing because it's blocked with condensate, and you're basically trapping that vacuum inside. So, the contacts will stay closed until the next call for heat. When that call starts, the contacts will already be closed before the inducer starts, and that will also give you an error (pressure switch stuck closed).

Now, if your exhaust is blocked, this will create back pressure. Your collector box won't be under the appropriate vacuum and, once again, won't close.

For millivolt systems:

Unfortunately, I can't say what typical resistance values would be for a millivolt (mV) gas valve because I don't know. I would say, however, that in three and a half years, I haven't had to replace a fireplace gas valve. They rarely go bad. In most cases, the pilot tube/orifice is dirty, the thermopile is too weak, or, if it works with a wall switch, it's very, very common that the switch is bad. Standard wall switches are meant for AC voltage.

Running millivolt DC through them will work, but as soon as you have a bit of resistance in the switch contacts, that voltage will not get through. If it runs on a thermostat, it usually works better, but you can still get the same problem.

For typical readings, I'd say you can expect between 450-650 mV from the thermopile alone, open circuit. With the valve open (so, closed circuit), expect around 200-300 mV. But these values are very general; they may vary a lot between systems.

If your thermopile alone doesn't produce enough mVs, check your pilot flame. Make sure it hits the thermopile well. You might be able to adjust it (on some valves) to make it bigger. As I mentioned, the orifice or tubing may be blocked. That is relatively common, especially if the pilot was kept off for a long time.

If your thermopile gives enough voltage, but the valve won't open, check your switch/thermostat and even the wire itself for any significant resistance or short.

Isolate section by section and ohm it out. If everything is good—sufficient mVs come back to the valve—but it still won't open, then yes, that valve might be bad. But I'd probably even replace a switch/thermostat before I condemn the valve regardless, just to be sure, because changing those valves is a total pain in the butt, in most cases.

For the gas valve/board dilemma:

If your wires are all in a harness with a big fat connector on the board, there's a good chance you won't be able to pull it off and diagnose on the board pins. By removing the connector, you remove most or all of the safety circuits.

If you want to look at the gas valve, you need to hook your meter on the wires at the valve itself. If it's just a standard 24v valve with 2 or 3 terminals (common + hot or common + low and high solenoids), just pull the wires off (or connector) at the valve, and you have to check for 24V on the wire across common and hot. Even with the valve disconnected, if your board is OK, it will still send 24V in that wire at the proper time in the sequence of operation (i.e., wait until the ignition sequence completes!!). If you don't have 24 volts, the board is bad. If you have 24V, the gas valve is bad.

If it's one of those Honeywell SmartValves, then that's another story entirely. A good portion of the controls are actually inside that gas valve, and it will have multiple wires going to it. They are a bit more difficult to diagnose. My best advice is to follow your electrical diagram. If there's no way for you to disconnect wires at either end (which should never happen, as far as I know), you could always cut the wire and check your voltage in the wire itself. But try to avoid doing that.

—Ben

Comments

Hypodermic meter leads will also allow you to check voltages on wires in molex plugs. As far as the thermo pile it can be tested under a flame for proper milivolt specs. Great content here with some good answers. How about some chiller or advnced refrigeration parts. Hot gas bypass. Liquid injection for superheat control and when it is used. Epr valves and their purpose.

Hypodermic meter leads will also allow you to check voltages on wires in molex plugs. As far as the thermo pile it can be tested under a flame for proper milivolt specs. Great content here with some good answers. How about some chiller or advnced refrigeration parts. Hot gas bypass. Liquid injection for superheat control and when it is used. Epr valves and their purpose.

https://bestiptvservice.vip

https://bestiptvservice.vip

pharmacie en ligne france livraison belgique: Livraison rapide – п»їpharmacie en ligne france pharmafst.com

pharmacie en ligne france livraison belgique: Livraison rapide – п»їpharmacie en ligne france pharmafst.com

pharmacie en ligne sans ordonnance п»їpharmacie en ligne france or Pharmacie en ligne livraison Europe

http://www.google.ga/url?q=https://pharmafst.com pharmacie en ligne pas cher

[url=https://toolbarqueries.google.com.ag/url?q=https://pharmafst.com]п»їpharmacie en ligne france[/url] trouver un mГ©dicament en pharmacie and [url=https://dongzong.my/forum/home.php?mod=space&uid=28767]pharmacie en ligne france livraison internationale[/url] pharmacie en ligne pas cher

pharmacie en ligne sans ordonnance п»їpharmacie en ligne france or Pharmacie en ligne livraison Europe

http://www.google.ga/url?q=https://pharmafst.com pharmacie en ligne pas cher

[url=https://toolbarqueries.google.com.ag/url?q=https://pharmafst.com]п»їpharmacie en ligne france[/url] trouver un mГ©dicament en pharmacie and [url=https://dongzong.my/forum/home.php?mod=space&uid=28767]pharmacie en ligne france livraison internationale[/url] pharmacie en ligne pas cher

https://kamagraprix.shop/# kamagra gel

https://kamagraprix.shop/# kamagra gel

Achat mГ©dicament en ligne fiable [url=http://pharmafst.com/#]pharmacie en ligne pas cher[/url] Pharmacie en ligne livraison Europe pharmafst.shop

Achat mГ©dicament en ligne fiable [url=http://pharmafst.com/#]pharmacie en ligne pas cher[/url] Pharmacie en ligne livraison Europe pharmafst.shop

Achetez vos kamagra medicaments: Kamagra pharmacie en ligne – kamagra 100mg prix

Achetez vos kamagra medicaments: Kamagra pharmacie en ligne – kamagra 100mg prix

kamagra pas cher: Acheter Kamagra site fiable – Kamagra pharmacie en ligne

kamagra pas cher: Acheter Kamagra site fiable – Kamagra pharmacie en ligne

Pharmacie en ligne Cialis sans ordonnance: Acheter Cialis – cialis prix tadalmed.shop

Pharmacie en ligne Cialis sans ordonnance: Acheter Cialis – cialis prix tadalmed.shop

olympe casino en ligne: olympe – olympe casino en ligne

olympe casino en ligne: olympe – olympe casino en ligne

Regarding board or control valve – always put a load on what your testing. Especially with today’s high impedance meters you can read a voltage from the board and then as soon as there is a load on it the voltage is gone. I plug an R8222 relay in place of the gas control valve and see if it pulls in. Nothing worse than replacing one part only to find out it was the other – Doh!!!

Regarding board or control valve – always put a load on what your testing. Especially with today’s high impedance meters you can read a voltage from the board and then as soon as there is a load on it the voltage is gone. I plug an R8222 relay in place of the gas control valve and see if it pulls in. Nothing worse than replacing one part only to find out it was the other – Doh!!!

pharmacie en ligne avec ordonnance [url=https://pharmafst.com/#]pharmacie en ligne sans ordonnance[/url] pharmacie en ligne avec ordonnance pharmafst.shop

pharmacie en ligne avec ordonnance [url=https://pharmafst.com/#]pharmacie en ligne sans ordonnance[/url] pharmacie en ligne avec ordonnance pharmafst.shop

To leave a comment, you need to log in.

Log In