Get Tech Tips

Subscribe to free tech tips.

Short Cycling

A friend of mine was telling me that a utility had the idea that they could reduce energy consumption by turning HVAC equipment on and off rapidly during times of high load. In their minds, wouldn't it be better to spread out the off time rather than keeping the system off for longer periods and allowing the space to become uncomfortable?

The answer is a HARD NO on that one!

Short-cycling is a condition where equipment goes on and off more than is optimal. Each time it goes on and off is called a cycle, and we (almost) always aim to keep run times long and cycles to a minimum. Sometimes short-cycling occurs due to a system fault, and it sometimes occurs due to a mismatch between system capacity and load (cooling or heating too quickly).

Short cycling is a problem for many reasons, including poor temperature control, inadequate dehumidification, rapid component failure, and the list goes on and on. RAPID short-cycling can quickly cause contact and relay failure due to arcing and can be very damaging to motors.

Let's look at some common conditions that cause short cycling.

Safeties, Limits, and Pressure Switches

Anytime there is an issue with the equipment that causes high temperatures or and high/low system pressures, there are often controls that shut the system off before a catastrophic failure occurs. Some common examples would be:

- Furnace limit switches

- Compressor and other motor overloads

- Refrigerant high, low, and loss of charge pressure switches

When one of these safety controls turns the system off, there will often be a time delay that prevents the equipment from coming right back on. In most of these switches, there will be a gap between the make and break (on and off) points in the switch, which will naturally help to prevent rapid short-cycling.

Loss of Power

When power is rapidly cycled (turned on and off), the components may go off and then back on quickly if there is no time delay. Here in Florida, this happens often during thunderstorms, but it can also be caused by flipping a breaker on and off rapidly or bumping a condensate switch. These sorts of rapid short-cycling events are hard on motors and controls, and they can even cause scroll compressors to run backward (on rare occasions).

Oversizing/Low Load

The way we control the temperature with most appliances is by running them until they hit the setpoint and then shutting them off. This can result in short run times when the load is low or when the equipment is oversized. The best designs result in the equipment running non-stop when during peak load; this isn't intuitive for most customers, and they will often complain that the system “never shuts off.” You can reassure them that so long as they are staying comfortable, never shutting off is a good thing for system longevity and power consumption.

Controls Design & Setup

The controls play a big part in run time, depending on how they are set up. It is almost never as simple as turning on and off at a set temperature because that would almost certainly result in short-cycling unless the system has variable capacity or the capacity is perfectly matched to the load. In most real-world conditions, the controls will need to manage a dead-band or gap between on and off to balance comfort and short cycling.

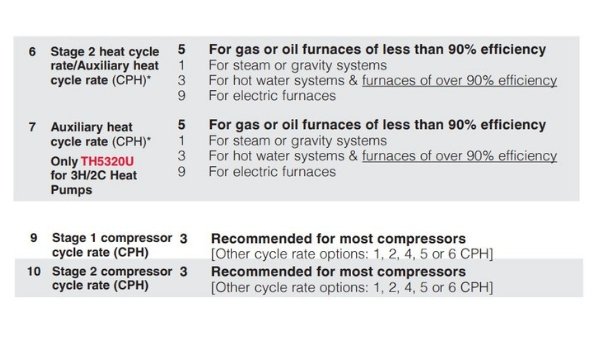

Controls do this by maintaining an on-off dead-band and maintaining a maximum CPH (cycles per hour), like the Honeywell thermostat shown above. This means that a thermostat with a 3-degree dead-band with a cooling CPH set to 3 and a set-point of 75 degrees would come on at 76 and shut off at 74 while turning on and off a maximum of 3 times per hour.

So, those are some of the factors that impact short cycling, but what are some of the issues associated with short cycling? Here is an incomplete list:

- Electrical system strain/low voltage to the rest of the structure during motor/compressor start-up

- Dimming lights

- Contactor/relay contact wear

- Premature HSI (hot surface ignitor) failure

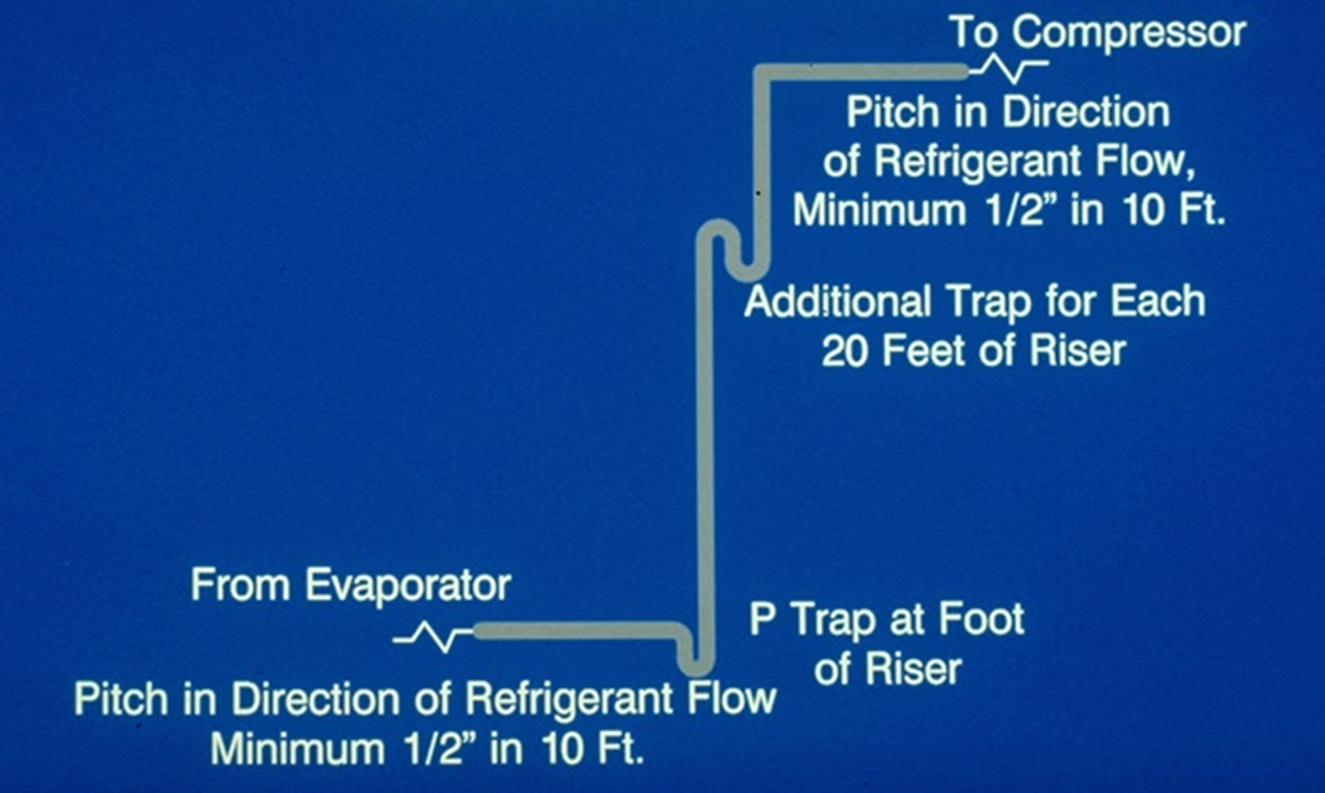

- Compressor oil loss and lubrication issues

- Poor dehumidification (it takes a while for the coil to cool down and dehumidify)

- Poor efficiency and system performance (it takes time for the system to get up to steady-state performance)

- Poor cooling/heating (when you short-cycle, you may heat and cool the air rapidly but may still have “stuff” in the home and structure that are hotter or cooler, resulting in radiant discomfort)

- Poor ventilation control

I'm sure you can think of many more.

The goal is to run long and steady cycles without any cutting in and out safeties and a good match of system capacity with the load. This helps us provide comfort, efficiency, and system longevity.

What are some short cycling issues you have seen?

—Bryan

Comments

Belt wear.

Pulley wear.

Bearing stress & wear.

Motor failures due to excessive thermal ranges and cycling. Motor life partly based on number of cycles. Need adequate time between cycles to cool. Dissimilar metals in rotor & stator have different thermal expansion rates. Can cause open rotor or stator spot/slot burns.

Noise from drive trains and duct flex.

Oil & refrigerant management. Split systems worse needing longer run cycles.

Typical dx coil takes 5-7 minutes to load and start draining condensate, expansion valves need time to stabilize, vendors state up to 15 minutes between any adjustments, start-up would typically require as much time as adjustments to stabilize, humidity issues/iaq issues

Air distribution/temperature control

Belt wear.

Pulley wear.

Bearing stress & wear.

Motor failures due to excessive thermal ranges and cycling. Motor life partly based on number of cycles. Need adequate time between cycles to cool. Dissimilar metals in rotor & stator have different thermal expansion rates. Can cause open rotor or stator spot/slot burns.

Noise from drive trains and duct flex.

Oil & refrigerant management. Split systems worse needing longer run cycles.

Typical dx coil takes 5-7 minutes to load and start draining condensate, expansion valves need time to stabilize, vendors state up to 15 minutes between any adjustments, start-up would typically require as much time as adjustments to stabilize, humidity issues/iaq issues

Air distribution/temperature control

It’s enormous that you are getting ideas from this piece of writing as well as from our discussion made here.

It’s enormous that you are getting ideas from this piece of writing as well as from our discussion made here.

To leave a comment, you need to log in.

Log In