Get Tech Tips

Subscribe to free tech tips.

Why Selecting Equipment is Important (and Hard)

I get questions all the time about performing “load calculations” and “rules of thumb” or how to do it properly. This article isn't about load calculation, but the only good answer is to find a quality ACCA-approved Manual J software and get used to using it.

You may have heard from others in the field that Manual J tends to “undersize” the equipment. If you are an engineer or designer, you may be shocked at how “oversized” most equipment is when compared to Manual J. Like most things, you can find the truth somewhere in between, and here are the reasons for this.

System selection is just as important as Manual J because if you don't match the proper equipment to the BTU load, or if you fail to consider the factors, you can easily end up with a system that is undersized or that does not deal with the humidity load of the space.

Here are some common factors that contractors & designers fail to factor into their Manual J properly.

Duct leakage rate

We can guess, but the only way to really KNOW the leakage rate is to do a duct leakage test like the one shown below by Corbett Lunsford.

Building Envelope Leakage Rate

The rate of leakage in and out of a structure is one of the most overlooked aspects of load calculation. Once again, we can guess based on the age and construction type, but the true leakage rate can vary wildly. The only true way to test leakage rate is by measuring it with a blower door.

Insulation

Even insulation is often a guess in areas where you cannot access walls or portions of the attic. It takes a combination of experience and thermal imaging or other R-value measuring tools to calculate heat loss/gain through insulation accurately.

Shade

This one is very challenging to calculate. You may have two homes with nearly identical construction, orientation, and layout, but one has significant shade from trees while the other does not. This shade can represent a significant decrease in radiant heat transfer to the walls, windows, and roof and will vary seasonally based on the season and various times of the day. Shade is something you can factor in using common sense. While I wouldn't suggest “under-sizing” just because of shade, you can be sure that a well-shaded structure will have lower radiant gains which will have an impact in all seasons.

Ventilation

For every cubic foot of air you move out of a building, you are also moving one cubic foot of air into the building, either through a designed path, through cracks and gaps, or when a door or window opens. One way or another, when you move air out, you are also moving it in. It is always better to move that air into the building through a designed path where the air can be controlled, measured, and likely treated (ERV, HRV, dehumidification) instead of through cracks and gaps in any number of undesirable places. In addition to this, new standards are being enforced surrounding ASHRAE 62.1 & 62.2 that mandate mechanical fresh air is brought into all structures. This fresh air needs to be considered as to heat gains and losses, both sensible and latent.

Because of all these factors and industry pressures, I have found that design professionals tend to underestimate heat gains and losses (on existing, untested structures). Conversely, contractors and field personnel tend to oversize equipment based on “experience,” “rules of thumb,” and usually a combination of both. That happens because it is much more common for a contractor to receive a complaint of a system “not keeping up” than humidity power consumption issues because the thermostat displays the temperature in big, bold numbers, while humidity and power are a bit more abstract.

Design professionals are under pressure not to oversize equipment by the industry (and rightfully so), but they may not be fully aware of all of the “as-built” conditions that exist.

But for the sake of argument, let's say the heating season losses and cooling season gains have been perfectly calculated.

We now bump up against some of the most common areas of misunderstanding by contractors and field staff, which is properly matching the equipment to the load. Here are some of the biggest mistakes:

- Failing to cover both sensible and latent (humidity) loads in the cooling season

- Using nominal tonnage of equipment to estimate capacity (no, a 3-ton cannot be counted on to produce 36,000 BTU)

- Looking at AHRI ratings to find capacity instead of at the manufacturer performance data

- Oversizing/undersizing either the heating or cooling side by considering one and not the other

To select equipment properly, it is recommended that you use ACCA manual S to ensure that you don't miss any of the steps. ACCA has a great quick guide on system selection that you can read HERE.

Here are some tests you can apply to your residential design to help double-check that your selection matches the design:

- The sensible cooling capacity of the system you choose should not be more than 15% greater than the sensible heat gain of the space.

- The latent cooling capacity of the system must be equal to or greater than the latent load of the space.

- In heat pump applications with greater heating loads than cooling loads (common), the cooling system must not be more than 25% of the sensible cooling gain.

- The heat pump + electric aux heat capacity should not exceed the heat loss by more than 15%.

- In fuel-burning appliances, choose the next size greater than the heat loss of the space.

All of these need to consider the manufacturers' specifications matching the load calculation conditions to the specifications of your equipment at the same conditions. While a furnace may produce the same heat output no matter the conditions, air conditioning and heat pump equipment output will change depending on indoor and outdoor conditions.

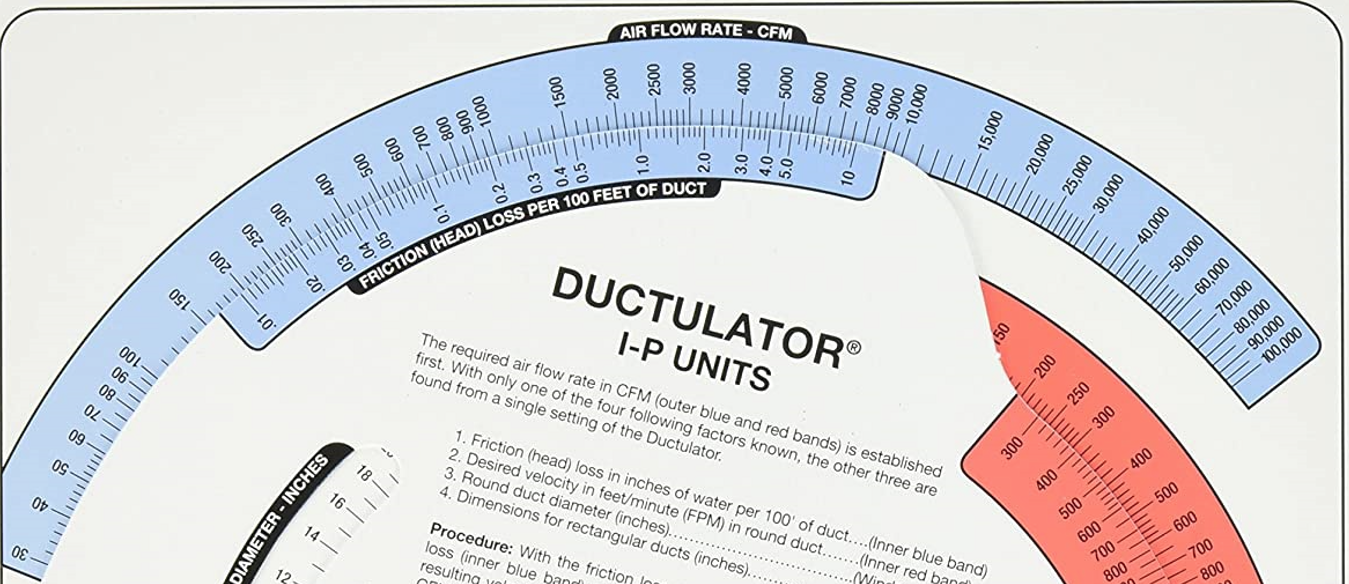

The final step is configuring the equipment to the proper airflow levels so that the sensible/latent capacity will match the design. If the system was designed for 400 CFM per ton, it is critical to ensure that the equipment is set to output that airflow.

—Bryan

Comments

Bryan,

On that note, in the MeasureQUICK app, the system information has a whole section that allows for the extended performance ratings of equipment to be entered as to test the equipment installation against its performance ratings as designed. This assures the system is configured with correct airflow, sensible capacity, latent capacity and total capacity. It also assures that when equipment is tested it is measured against its actual ratings which are often far from nominal.

Bryan,

On that note, in the MeasureQUICK app, the system information has a whole section that allows for the extended performance ratings of equipment to be entered as to test the equipment installation against its performance ratings as designed. This assures the system is configured with correct airflow, sensible capacity, latent capacity and total capacity. It also assures that when equipment is tested it is measured against its actual ratings which are often far from nominal.

The over sizing guidelines for heat pumps in the artical and a few years old. The current version of Manual S (end of 2014) should be used to update the article.

The over sizing guidelines for heat pumps in the artical and a few years old. The current version of Manual S (end of 2014) should be used to update the article.

To leave a comment, you need to log in.

Log In