Get Tech Tips

Subscribe to free tech tips.

Refrigeration Pump-down Cycle

This article was written by Jeremy Smith CM, an experienced refrigeration tech and all-around great dude. Thanks, Jeremy.

A very common means of control seen on refrigeration equipment is the pump down control. Why do we use this rather than just cycling the compressor off and on like a residential HVAC unit?

Since most refrigeration equipment tends to be located outdoors, it comes down to ambient temperatures and the basic properties of refrigerants we all understand (temperature and pressure) and how they can conspire to kill a compressor.

During periods of low ambient temperatures, if we merely cycled the compressor off, it could easily get colder at the compressor than inside the space. If the compressor cycles off for long enough, as it would during a defrost cycle, refrigerant vapor will start to condense within the crankcase. If we are lucky, the extent of this problem will be a unit that doesn’t start because the pressure of the refrigerant is lower than the cut-in setting of the pressure control. However, what typically happens is that enough refrigerant will condense to start to settle under the lubricating oil, causing a lack of lubrication upon restarting, leading to bearing wear and premature failure. If enough refrigerant condenses within the compressor housing, the resulting damage could cause valves, pistons, and other internal parts to break if liquid gets into the cylinders.

How can we prevent this?

One thing that is applied across almost all sectors of our industry is crankcase heaters. These small heaters, either immersion-style heaters or wrap-around style heaters, add a small amount of heat to help keep the compressor oil warm and help to prevent vapor from condensing there. The effectiveness of these is limited by the wattage of the heater, the ambient temperature, and the size of the compressor. Too low an ambient or too large a compressor, and they start to lose some effectiveness. (Read more about crankcase heaters HERE.)

So, how else can we prevent condensation within the compressor? Let’s look at the pressure/temperature relationship of refrigerants for the answer. If we lower the pressure in the crankcase to a point where the saturation temperature of the refrigerant is below the ambient temperature the compressor is in, the refrigerant cannot condense. This is why we use a “pump down” type system.

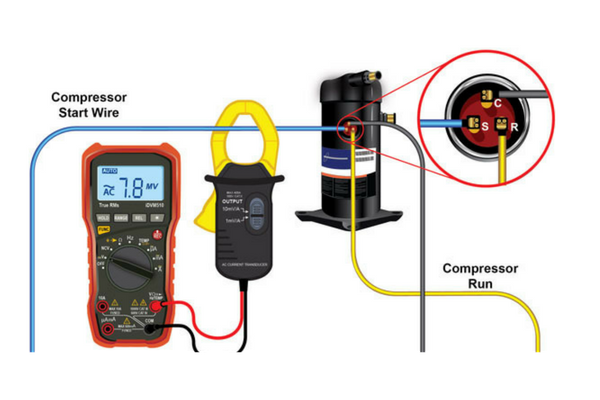

In operation, a pump down control consists of little more than a liquid line solenoid valve, a thermostat control, and a low-pressure control. When the thermostat or defrost control opens, the solenoid de-energizes, stopping the refrigerant flow and allowing the system to pump the suction pressure down before the low-pressure control turns the compressor off.

How low should we set that cut-out? The Heatcraft installation manual has us setting the cut-out as low as 1” Hg vacuum, depending on the minimum expected ambient. I like to set the cut-in just below the lowest expected ambient temperature so that you don’t wind up in a situation like the one I mentioned earlier. If the ambient gets too low and the cut-in is too high, your unit won’t cycle on until it warms up enough, resulting in a preventable service call.

Combining a pump down control with a crankcase heater and ensuring that all controls work properly at all times can save your compressor from damage in cold weather.

—Jeremy Smith, CM

Comments

Jeremy great article. Just to add you want to make sure you do not go outside the operation envelop of the compressor when setting both the low and high pressure controls as this could lead to a premature failure potentially due to high compression ratios. There are a few exceptions for low temp compressors. Anyone can search Emersons online product information or google Product Selection Software to find any Copeland operation envelop or performance sheets.

Jeremy great article. Just to add you want to make sure you do not go outside the operation envelop of the compressor when setting both the low and high pressure controls as this could lead to a premature failure potentially due to high compression ratios. There are a few exceptions for low temp compressors. Anyone can search Emersons online product information or google Product Selection Software to find any Copeland operation envelop or performance sheets.

Thanks for the strategies you have discussed here. On top of that, I believe there are several factors which really keep your car insurance policy premium straight down. One is, to take into consideration buying automobiles that are from the good list of car insurance providers. Cars which might be expensive will be more at risk of being lost. Aside from that insurance coverage is also depending on the value of your automobile, so the more costly it is, then the higher the premium you only pay.

Thanks for the strategies you have discussed here. On top of that, I believe there are several factors which really keep your car insurance policy premium straight down. One is, to take into consideration buying automobiles that are from the good list of car insurance providers. Cars which might be expensive will be more at risk of being lost. Aside from that insurance coverage is also depending on the value of your automobile, so the more costly it is, then the higher the premium you only pay.

To leave a comment, you need to log in.

Log In