Get Tech Tips

Subscribe to free tech tips.

Refrigeration Equipment Diagnosis Method

I was watching this video on the HVACR Videos channel by my friend Chris Stephens, and I was impressed by how completely he diagnoses the system both visually and with his tools. Take a look.

I say this all the time, but a good, efficient technician is one who sees everything and can also quickly diagnose the main thing.

First off, this isn't shown in the video, but Chris knows what type of appliance this is, what sequence of operation it runs in, and how the controls work. He likely knows all of this because he has a ton of experience with these freezers. If he didn't, then the first course of action would be to do a bit of reading up on the manufacturer's site or app so that you have the basics before proceeding.

So, let's explore everything Chris found and how he found it.

- Failed door seal

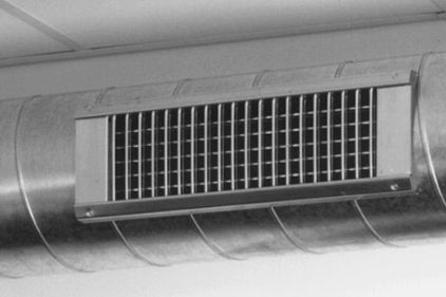

- Dirty condenser coil

- Frozen evaporator coil

- Defrost heater inoperable

- Failed defrost limit

The main thing wrong with this machine is a failed defrost limit, but Chris was able to diagnose the problem quickly because he used these skills of perception:

- Cycling a defrost mode (prior knowledge of the equipment or reading the manual)

- Noticing how quickly the suction line froze (visual and touch)

- Visual observation of the frozen coil (visual)

- Looking at the wiring diagram to find the circuit (diagram reading)

- Testing for voltage to the defrost heater (electrical diagnosis)

- Measuring amperage on the heater circuit to see if it is working (electrical diagnosis)

- Looking at the diagram again and finding a limit inline (diagram reading)

- Finding the high limit failed open (electrical diagnosis)

In addition to these efficient diagnosis skills, Chris was thinking about:

- Proper authorization for repair (getting approval before defrost)

- Protecting the equipment and workspace (covering the control with a bag)

- Noting and quoting other repairs needed for optimum performance (condenser coil cleaning, door seal)

These additional diagnosis items for optimum performance took no additional time. They will result in a more profitable repair ticket and a piece of equipment that will run better, with lower power consumption and less likelihood of an expensive callback.

You will notice that his first instinct wasn't to hook up gauges or use fancy tools. In this case, he really didn't need them; it would have only wasted time. When he returns, he will make the repairs and observe temperatures only to gauge the progress of the machine to ensure it's going to get to and maintain temperature.

In refrigeration, especially small refrigeration like this, you need to think about:

- Coil cleanliness (condenser & evaporator)

- Fan and compressor operation (is everything running when it should and going off when it should?)

- Defrost type and function (is it coming in and out of defrost?)

- Product and boxes aren't in the way of proper condenser or evap airflow

- Door seals are in good shape

- Door fits properly, and the hinges aren't bent or damaged

- Box achieves and maintains the proper temperature for the product contained within

Of course, there is a time to connect gauges or probes, and refrigeration is no exception, but the best techs use their senses first, knowledge of the equipment or reading second, and their tools only once they know exactly what they are looking for.

Great job, Chris! and I would suggest subscribing to his channel HERE.

—Bryan

Comments

To leave a comment, you need to log in.

Log In