Get Tech Tips

Subscribe to free tech tips.

Properly Diagnosing a Gas Furnace Pressure Switch

This article was written by boiler technician Justin Skinner. Big thanks to Justin for being one of the rare techs who cares enough to take the time to write something like this. Thank you, Justin!

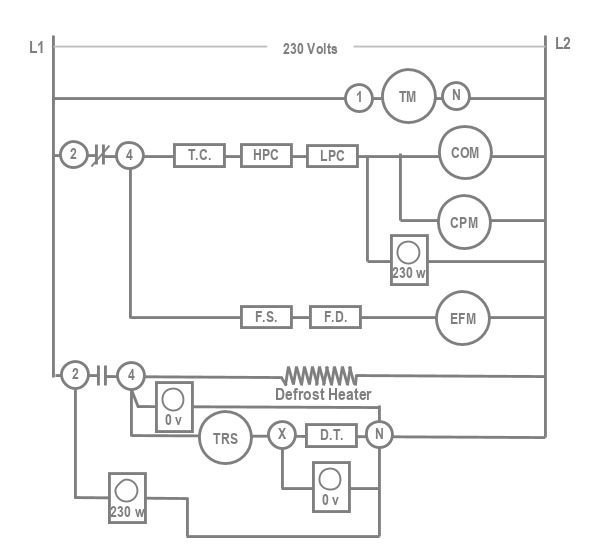

Pressure switches are used in a variety of applications. Generally, they are a normally open switch that closes with either a rise or fall in the pressure it is monitoring, They are used mostly as a safety device but are also used for operation control, such as fan cycle controls for low ambient cooling, starting and stopping for steam boilers, and the list goes on. Today, I am focusing on the pressure switch used in gas furnaces that prove inducer fan operation.

As noted above, the pressure switches used for gas furnaces are almost always normally open.

The board first checks the switch to ensure it is open prior to the inducer call. If it is closed prior to the call, it will go into fault because the switch is clearly jumpered, the circuit shorted, or the switch failed closed.

During preignition, when the inducer motor is running before the flame is established, it draws the heat exchanger into a negative pressure (draft). The pressure switch is used to prove this draft by a connection, typically rubber or vinyl tubing, directly to the heat exchanger or to the inducer draft motor housing. In the normal sequence of operations, if the pressure switch does not close during this preignition period, the control board will not allow the furnace to light. This is to ensure a few things. First, that the inducer motor is operational and not failed (inducer wheel broken, etc.). Second, it proves that the exhaust pathways are clear. If the chimney is caving in, or Mr. squirrel makes a nest in the top of the flue stack, the inducer motor will not be able to establish the draft (negative pressure) required to close the switch. The switch should also stay closed during the entire run cycle.

If the control board determines that the inducer motor has been running for an allotted amount of time and the pressure switch has not closed, it will lock out the furnace and go into a fault situation. It also locks out into fault if the switch opens enough times while the flame is lit. We will use Carrier as an example. When the switch does not close or opens during operation, and the furnace locks out, the led light on the control board flashes a fault code 31, which indicates the switch did not close. If the switch does not open after the furnace satisfies the heating demand and tries to start again, the board will flash a code 23. Code 23 would be seen as two short flashes, followed by three long flashes.

So, what's the proper procedure for troubleshooting if you come across a furnace displaying these fault codes? Most of the time, the issue is pretty apparent after you reset the board and run the furnace. The inducer motor is failed, or a family of opossums used the chimney base as their summer home, or most uncommon of all, the pressure switch is bad. But what about when it's not so apparent? When you reset the board and the furnace lights, and it runs fine, and the customer runs down and tells you how great you are? More than likely, if you leave it at that, that same customer who praised you will be calling in again but probably won't be as happy with your service skills as before. So, let's dig in and check a few more things.

In the thousands of no heat calls I have run, I can count the number of pressure switches that failed on their own with no other factors on the one hand. They just don't fail very often. I would need a lot more hands to count the callbacks I've run where another tech condemned and replaced a pressure switch, only to have the same issue not long after.

Callbacks cost money, and they always hurt my pride when they were mine, so the goal is to save both. So, the first thing to do in this situation is slow down. This time of year (December) is crazy busy for everyone, but the most important call you will run today is the run you are on right now. When I am in a hurry, I'm much more likely to miss things, and when that happens, I normally end up coming back to the call anyway.

Next, grab your trusty volt/amp meter and manometer. I prefer the digital version for both. Check incoming voltage to the furnace and make sure it is within spec of the voltage rating on the data tag. Check the amperage rating on the inducer motor, and make sure the actual amperage is in range. Let the inducer motor run for a while. If the amperage starts to go up substantially, or the motor gets noisy or too hot to touch, there is potentially a motor issue. Check the tubing that connects the pressure switch to the draft point. Look for cracks, brittleness, and crud or water inside the tubes.

If you see anything, clean it out. Hook a manometer to the tubing and check the draft from the heat exchanger in inches W.C. with a manometer or Magnehelic. The pressure switch has a pressure at which it closes, which is typically negative. Ensure the draft is above the required pressure. By this point on an 80% efficiency furnace, if you haven't found the culprit, you will have to put on your best thinking cap because the issue could be any number of things, including a bad board, loose or bad wire connections, or a bad pressure switch.

If you are working on a 90+% (condensing) furnace, move to the condensate drain. These furnaces produce water as a result of lower exhaust temperatures, and that water is removed from the furnace in a few ways. Carrier has a condensate trap that is a white box that mounts in the blower compartment on an upflow application. If this trap is partially clogged, water can back up in the secondary heat exchanger. This can prevent the necessary air movement required to produce enough draft to close the pressure switch. And if it's only partially clogged, it may have drained when the furnace was locked out and not running. So when you get there and reset it, everything runs fine until the condensate starts to back up again. Also, where the condensate water goes after it leaves the furnace is important to note. Does it go to a condensate pump? Does that pump the water outside? Is it freezing outside? It could have been last night, which caused water to back up and the furnace to lock out, but today, it's 40 degrees, everything has melted, and it's running smoothly.

These are just a few things I've seen with consistency over the years, but the potential number of causes for the fault codes listed above are almost limitless. And every heating season, I run into an issue I haven't seen before. This is in no way a comprehensive checklist. The goal of this is to prevent a technician from replacing too many parts that don't need to be replaced, which I did early on more times than I'd like to admit. Have a safe and merry heating season, and as we all hear from time to time, don't be a hack!

—Justin Skinner

Comments

Great article but misses many issues like undersized vents, undersized intakes.

Poorly pitched vents intakes.

Combustion air and combustions settings. Gas pressure.

Modulationing inducers that calibrate per cycle.

Should be a little more on the common problems list

Great article but misses many issues like undersized vents, undersized intakes.

Poorly pitched vents intakes.

Combustion air and combustions settings. Gas pressure.

Modulationing inducers that calibrate per cycle.

Should be a little more on the common problems list

The one I have seen multiple times was incorrect furnace levelling on install and slope leads away from condensate trap

Water builds up in condensate pan then starts lifting into inducer blower.

Easy to check, throw a level on 2 sides of furnace ensure minimum slope is there.

The one I have seen multiple times was incorrect furnace levelling on install and slope leads away from condensate trap

Water builds up in condensate pan then starts lifting into inducer blower.

Easy to check, throw a level on 2 sides of furnace ensure minimum slope is there.

Very well done! I agree, these switches rarely fail!

A lot of the times I see corrosion blocking flow in the tiny opening in the nipple attached to the top of the HX.

Very well done! I agree, these switches rarely fail!

A lot of the times I see corrosion blocking flow in the tiny opening in the nipple attached to the top of the HX.

Bryan, I am a coworker of Justins’ and would prefer to see his posts’ grammatically correct. Please thoroughly proofread before posting. If you feel you could use assistance in the matter, contact me for arrangements.

Best!

Bryan, I am a coworker of Justins’ and would prefer to see his posts’ grammatically correct. Please thoroughly proofread before posting. If you feel you could use assistance in the matter, contact me for arrangements.

Best!

Justin told me to beware of Dale and his “grammar skills” do you know what he could mean by that?

Justin told me to beware of Dale and his “grammar skills” do you know what he could mean by that?

In the paragraph…

“The board first checks the switch to ensure it is open prior to inducer call. If it is closer prior to call it will go into fault because the switch is clearly jumpered, the circuit shorted or the switch failed closed.”

“Closer” should be “closed”.

In the paragraph…

“The board first checks the switch to ensure it is open prior to inducer call. If it is closer prior to call it will go into fault because the switch is clearly jumpered, the circuit shorted or the switch failed closed.”

“Closer” should be “closed”.

Check the voltage drop across the contacts when it is closed. More than 0.1Vac and the contacts are starting to pit. Replace it or you will get intermittent no-heat calls.

Check the voltage drop across the contacts when it is closed. More than 0.1Vac and the contacts are starting to pit. Replace it or you will get intermittent no-heat calls.

Another reason for a fault is a blocked or partualy blocked venturi on the fan.clean or replace the venturi.

Make sure if you have to replace the pressure switch,its the right one, not all the pressure switches opperate with the same pressure differential.

Another reason for a fault is a blocked or partualy blocked venturi on the fan.clean or replace the venturi.

Make sure if you have to replace the pressure switch,its the right one, not all the pressure switches opperate with the same pressure differential.

Great Read I like the part about Slow Down don’t hurry

Great Read I like the part about Slow Down don’t hurry

A blocked exhaust can cause that too. If a flue cap is damaged or is damaged where it blocks the flue exit, the switch can open.

Also, the drain for a 90% efficient furnace has to be trapped/drained separately from an A/C condensate drain. If not, positive fan pressure can sneak through the furnace drain and create uneven pressure for the pressure switch.

I’ve also found blockages in the PVC exhaust piping also.

This article is on point. If the drain clogs, there will be intermittent pressure switch problems.

A blocked exhaust can cause that too. If a flue cap is damaged or is damaged where it blocks the flue exit, the switch can open.

Also, the drain for a 90% efficient furnace has to be trapped/drained separately from an A/C condensate drain. If not, positive fan pressure can sneak through the furnace drain and create uneven pressure for the pressure switch.

I’ve also found blockages in the PVC exhaust piping also.

This article is on point. If the drain clogs, there will be intermittent pressure switch problems.

I feel like you just touched on the subject. If any tech been doing this for a time we know that pressure switch don’t just fail. Flu issues, partially plug secondary heat exchanger. I understand that the pressure switch error is a very tough to get right the first time. Besides the obvious.

I feel like you just touched on the subject. If any tech been doing this for a time we know that pressure switch don’t just fail. Flu issues, partially plug secondary heat exchanger. I understand that the pressure switch error is a very tough to get right the first time. Besides the obvious.

Also Gentleman, in the blocked flue arena, I have found that ‘stink bugs’ in particular, enjoy crawling down the exhaust into the manifold and blocking the drain tube. This can be remedied by buying a cheap pvc end cap screen on ebay and save some real trouble..

Also Gentleman, in the blocked flue arena, I have found that ‘stink bugs’ in particular, enjoy crawling down the exhaust into the manifold and blocking the drain tube. This can be remedied by buying a cheap pvc end cap screen on ebay and save some real trouble..

Can you tell me if the switch should hold a vacuum? Diaphragms can leak, and when I was just checking my LP switch, it would not stay closed (ie., hold vacuum) for more than about ten seconds.

Can you tell me if the switch should hold a vacuum? Diaphragms can leak, and when I was just checking my LP switch, it would not stay closed (ie., hold vacuum) for more than about ten seconds.

If you work in the HVAC industry, you should read this article. The diagnostic procedure for a gas furnace pressure switch is well-described and easy to follow. Technicians who run across similar problems will appreciate the troubleshooting advice and overview of the pressure switch’s operation. Wow, I really appreciate you posting this.

For More Info : https://www.teltherm.co.nz/

If you work in the HVAC industry, you should read this article. The diagnostic procedure for a gas furnace pressure switch is well-described and easy to follow. Technicians who run across similar problems will appreciate the troubleshooting advice and overview of the pressure switch’s operation. Wow, I really appreciate you posting this.

For More Info : https://www.teltherm.co.nz/

To leave a comment, you need to log in.

Log In