Get Tech Tips

Subscribe to free tech tips.

Potential for Good and Evil (The Hard Start & Potential Relay)

I have spent most of my career being afraid of hard start kits; I heard too many horror stories of start caps exploding and sales technicians telling every customer they need one.

It dawned on me recently that it may be time for me to take a more mature look at start capacitors, potential relays, and hard start kits and find some best practices.

First, be aware that not everything commonly called a “hard start” is the same thing. The bottom of the barrel is called a PTCR, which is essentially just a resistor that starts off at a low resistance when cool and changes to higher resistance when it gets hot. It creates a direct path from L2 (run side) through the start winding. As soon as it heats up, the higher resistance essentially removes it from the circuit. That is NOT the same technology as a start capacitor in any way. In my experience, they don't work well and are prone to failure, at least in air conditioning systems. (Note: some people may call PTCRs “soft starts.” These are NOT soft starts!)

There are also electronic and timer-type “start kits” that use a capacitor but remove it from the circuit using a timer.

However, the most traditional and time-tested method of start assisting a compressor in HVAC is the good old start capacitor and the potential relay.

How Start Capacitors and Potential Relays Work

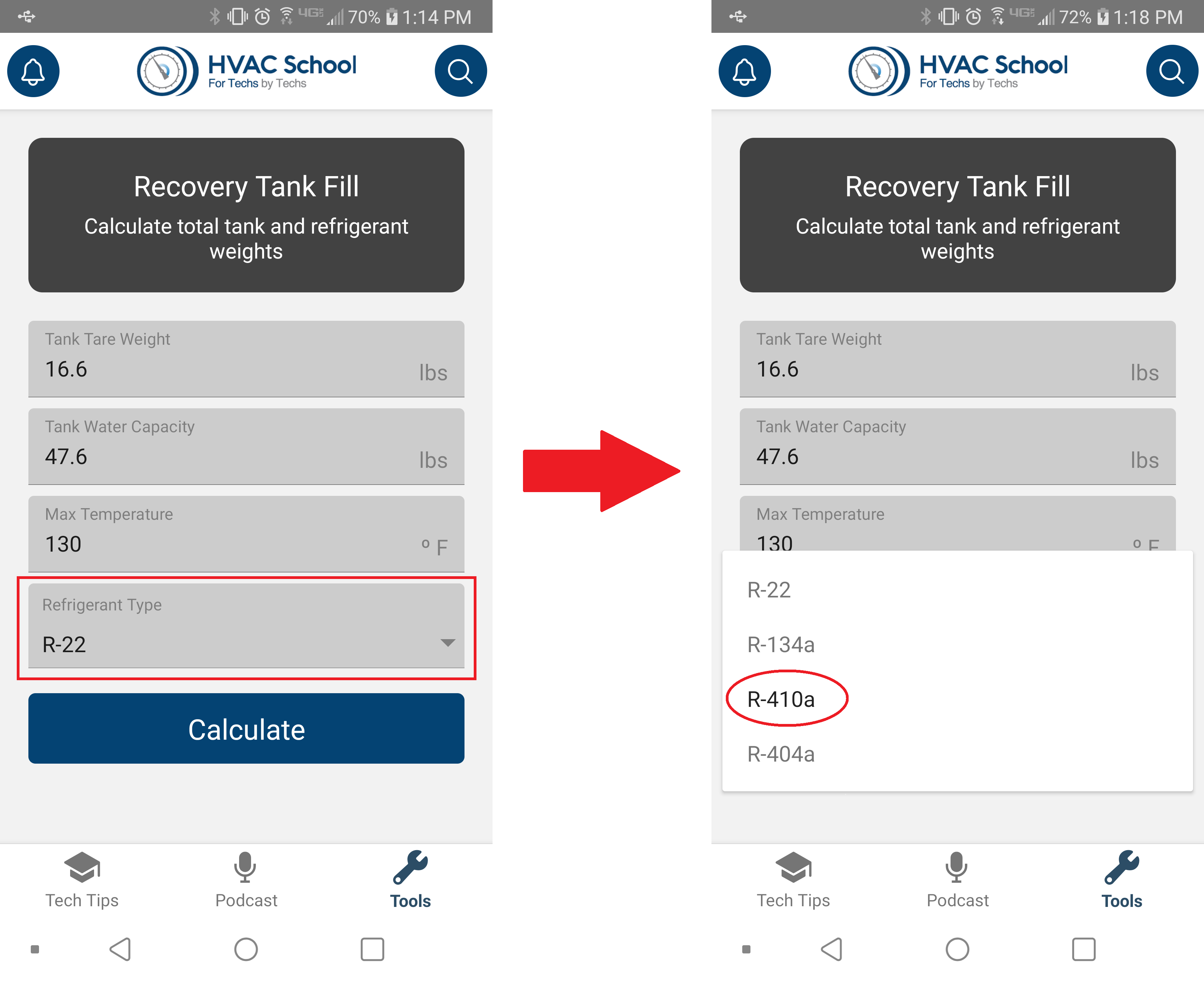

Photo Courtesy of Rectorseal

When a compressor first starts up, it requires a lot of torque to get from 0% up to 75% of its running speed. That's especially true when it starts under pressure load (unequalized pressures). A start capacitor is designed to create the optimal phase shift for that first 75% of synchronous speed. A run capacitor is sized to create an optimal phase shift for a compressor running at full speed and full design load because the run capacitor never comes out of the circuit.

Photo Courtesy of Rectorseal

While a run capacitor has heat dissipation capability for constant duty, a start capacitor MUST be taken out of the circuit VERY quickly. Otherwise, you risk melting down and causing compressor damage.

The start capacitor is REMOVED from the circuit by a relay called the potential relay. The potential relay is normally closed, and it OPENS when a sufficient PICKUP voltage is present between the 5 and 2 terminals on the relay. This pickup voltage is the potential (voltage) that exists in the start winding when a motor gets above about 75% running speed. It is generated in the start winding by the motor itself, NOT the capacitor.

A capacitor DOES NOT boost the voltage. When you see that increased voltage across the capacitor, that is back EMF being generated by the motor, just like in a generator (pretty cool, huh?).

Once the compressor shuts off the relay, it then DROPS OUT, which closes the contacts again for the next time.

Some hard start manufacturers wire the coil on the potential between start and common. Others wire it between start and run. You will find that most OEMs wire between start and common, but this does not mean that wiring between start and run is bad; it just needs to be designed correctly for that purpose (Kickstart does it this way).

When to Use a Start Capacitor and Potential Relay

A properly sized start capacitor and potential relay are not BAD for a compressor. However, they must be sized and installed correctly, and there are some cases where they are more likely to be useful than others. When in doubt, a factory start capacitor with a potential relay is the best and safest bet.

Cases where they may be very useful:

- Long line set applications

- Hard shut off expansion valves

- More often on reciprocating compressors than scroll or rotary (but still OK on scroll and rotary when beneficial)

- On 208V single-phase applications

Things to consider:

- Mount the relay properly; there is a proper UP configuration on most potential relays.

- Use hard starts with REAL potential relays, not timers, solid-state, or other relay types (in my experience).

- Size the relay and capacitor according to the manufacturer's specs.

- Ensure that you have a good-quality, properly sized run capacitor on any system with a hard start.

It's also worth noting that hard start kits do NOT reduce starting current. Your meter will likely show a smaller number of amps on startup when there's a hard start kit in the circuit, but that's a time-averaged measurement. Some “soft starts,” however, do reduce the starting current. You can learn more about soft starts like the Micro-Air EasyStart from THIS video.

If you want to learn more about potential relays, you can read some useful ACHR News articles, “Potential Relay Ratings and Specifications” and “Know Your Potential Starting Relays.”

Also, we have a podcast out with the technical manager for Rectorseal, James Bowman, HERE.

—Bryan

Comments

To leave a comment, you need to log in.

Log In