Get Tech Tips

Subscribe to free tech tips.

Mini-Splits for New HVAC Techs

This article was written by Ryan Findley. Thanks, Ryan!

This article will be geared toward HVAC techs who are new to mini-splits. As the mini-split market continues to grow, technicians face more and more challenges with these systems. The most critical challenges would be insufficient training and the lack of proper tools to work on mini-splits effectively.

To start, I advise going to as much manufacturer training as your employer will allow. I will give you some highlights of how mini-splits work, how to troubleshoot them, and what tools you will need to be effective at troubleshooting them.

How mini-splits are different

Mini-splits, like their bigger VRF machine cousins, have a lot of mystique that surrounds them. In my opinion, they don’t warrant the mystique. Mini-splits still operate under the same rules of thermodynamics that standard unitary equipment does. They just function a little differently. Let’s dive into what’s different about them.

Inverter-driven compressors: Right from the start, these systems use an inverter-driven compressor to control capacity (some have an AC compressor, others have a DC compressor; refer to the manufacturer’s literature or data plate). A circuit board has two possible functions. It may rectify incoming power to DC before inverting it back to AC to drive the compressor, or it may merely control the DC output to produce a variable speed effect.

Compressor speeds are a function of meeting either the target evaporator temperature (cooling mode) or the target condensing temperature (heating mode). TE (target evaporator) and TC (target condenser) calculation come from how far off setpoint the return air temperature, room controller temperature, or remote controller temperature is. The further off the setpoint is, the faster the compressor will run (the lower the TE or higher the TC). Run speed is typically published in RPS (revolutions per second). The typical range on most units is 25-120 RPS.

EEVs: Electronic expansion valves are electronically controlled devices that meter the flow of refrigerant through the system. One-to-one units will have one expansion valve, while multi-splits will have one per port. If it’s a four-port unit, there will be four EEVs in the machine.

Each EEV controls refrigerant flow to each indoor coil attached. EEVs either control the superheat (AC mode) or the subcooling (heating mode). We aim to get these values to specific numbers, called superheat/subcooling targets. Superheat/subcooling targets are anywhere from 8-15° F and typically vary depending on how far off setpoint you are. This is important information to remember, as it will help you evaluate the charge without weighing it out just yet. We will touch on EEVs again later.

Four-Way Valve: Commonly called the reversing valve in unitary equipment, a four-way valve diverts refrigerant to the indoor coil for heating mode or outdoor coil for cooling mode. Most manufacturers' valves default to cooling and energize in heating mode.

Thermistors: Thermistors are devices that change resistance based on temperature. Common thermistor types are discharge pipe temp, gas pipe temp, liquid pipe temp, room temp, return air temp, inverter temp, and compressor body temp, to name a few. There are many different thermistor ohm ratings. Refer to your specific manufacturer’s literature for your temperature to resistance charts. Common ones are 10k thermistors, which come in PTC or NTC varieties.

Protection Modes: Unlike traditional unitary systems, mini-splits use many forms of protection control to prevent serious damage from occurring. Different manufacturers have different limits, but generally speaking, they all look at the same things. Some examples are:

- Low-Pressure Protection: Once the unit gets below a certain suction pressure, the compressor will be commanded to slow down or maintain its current speed. There’s a possibility you can get hung up in a low-pressure stepdown where it doesn’t get high enough to allow it to try to ramp up again, so it will look to you as if the machine is just running at a low RPS.

- High-Pressure Protection: Once the unit hits a certain head pressure, compressor speeds will be limited and slowed down if needed to lower the discharge pressure.

- Discharge Temperature Stepdown: Discharge pipe temperature step down occurs if the thermistor on the compressor’s discharge line is too hot. This could mean any number of things, but one of which could mean it’s low on refrigerant. The machine will limit the compressor speed to save the compressor from being damaged.

- Inverter Temperature Step: If the temperature of the inverter board heat sink becomes too hot, inverter operation could stop, or compressor speed will slow down to prevent damage to the board. You could run into this if someone recently replaced the board without applying heat sink paste. It’s also imperative that all screws get replaced in the proper position, or you will not get good contact on the heat sink, and the board will likely overheat.

- Piping Diagrams: Below, you’ll see a typical piping diagram shown in a service manual. These can be helpful tools in troubleshooting an issue. Note that the red arrows indicate flow direction during heating operation and blue for cooling operation. The upper line coming into the four-way valve is always discharge gas, and the middle line coming out of the four-way valve is always suction gas. This unit’s EEV is also located in the outdoor unit, meaning the lines leaving the outdoor unit are the expansion line and the gas pipeline.

Tools Required: If you are going to work on mini-splits, there are a couple of items that you MUST HAVE. A good multimeter that can read a high resistance is an ABSOLUTE MUST HAVE. Most thermistors’ values are 5-75K ohms. If you do not have a meter capable of reading that high of a resistance value, it will show you an OL even though the thermistor isn’t actually open. Instead, it’s just a value that’s higher than what your meter is capable of reading. If you’re unsure, check the spec sheet for your respective meter. Make sure you have a nitrogen regulator that is capable of 600 PSIG. That way, the proper pressure test can be performed. I also recommend having a good thermometer that’s capable of reading pipe temperature.

Common issues

Let’s touch on a couple of things that could very well help you out if you are on a mini-split call.

1. Leaking Flares: Leaking flares are among the most common causes for a service call and one of the easiest to avoid. Using a good, sharp blade on your tubing cutter, deburring the copper, making a proper flare (using an orbital flaring tool with clutch), checking it with a flare gauge, and tightening it to the proper torque settings are the keys to avoid this from happening. Expansion and contraction put the flare under a huge amount of stress changing between modes. See Bryan’s tech tip for more info: https://www.hvacrschool.com/making-flare-quick-tips/

2. Communication Problems: Communication problems can stem from any number of things. Hit the basics first. Make sure your wiring terminations are correct, as most use a 1, 2, 3 configuration. Ensure any external safety circuit wiring, like a condensate overflow switch, is wired properly, drains are clear, and condensate pumps are in working order. Generally speaking, most manufacturers use the third wire and one of the other high voltage conductors as a traveler wire (or common if you want to look at it that way). You can check between either 1-3 or 2-3 (again, this depends on the manufacturer; refer to the manufacturer for specs). You will typically look for a fluctuating DC voltage signal from 30-100 VDC. If you remove the third wire from the outdoor unit and check for VDC coming from the outdoor unit and the indoor unit, you could narrow your work by seeing if there is one voltage that is not fluctuating. Continue to narrow your work until you can identify the issue or the failed component.

3. Refrigerant Leaks: See #1 for the most common places to find refrigerant leaks. Improperly made and improperly tightened flares seem to account for a large majority of the refrigerant leaks.

How do I know if the machine is low on refrigerant? Good question. While superheat and subcooling can’t tell you the whole story, don’t discount the data you can gather from it. Look in the manual and determine how the machine's EEVs are being controlled (see the above explanation on how target superheat and target subcooling are achieved). Once you have established that, it is possible to determine whether you are low or not.

I will typically run the machine in full heat or full cool (whichever the conditions allow) then observe what the superheat is doing. Most machines seem to run between 4-10 degrees of suction superheat in both heating and cooling mode. Remember that in heating mode, the big line leaving the unit is actually discharge gas (so please don’t call it the suction line because it isn’t). You need to take your pipe temperature exiting the outdoor coil to see what the suction superheat is. Once you’ve established that it is low, the best practice is to pull the entire charge, pressure test, evacuate, and recharge. If a flare is “loose,” please don’t tighten it. Take it apart and remake it; it only takes a few minutes. You save more time by remaking it early than responding to a callback when it leaks again.

4. EEV Issues: Troubleshooting EEV issues can be very complicated. First, you need to understand where to find the information on how to check them out. Refer to the manufacturer’s published documents for the ratings of each type of EEV coil. Make sure you bring your needle leads, or you’ll break the plug. If the motor ohms out fine, you should check the voltage coming out of the board (typically 12 VDC) and verify that the board is outputting the voltage. As the valve is driving, you’ll see the voltage pulsing, so keep that in mind. If you don’t see the pulsing voltage when the valve should be driving, consider looking at the board. Numerous EEV donut magnets can allow you to operate the valve body by hand (https://weatherallreps.com/shop/ols/categories/specialized-tools).

*NOTE: The board and the valve have no way of knowing if they are out of sequence, so if you move the valve, you need to return it to a spot that the board will know where it is at startup. I suggest running it all the way closed then cycling the power to the machine. If this is not done, compressor failure can and will occur.

** Along with the EEV donut, there is also a handheld EEV driver that fits most manufacturers’ EEV plugs. The driver allows you to operate the EEV by hand. (https://youtu.be/xUVV80BcU1M email eevmatetech@gmail.com for more info) EEV issues can show up in a starved coil (typical) or a flooded coil. Knowing how to measure the superheat effectively will help you determine what you’re dealing with.

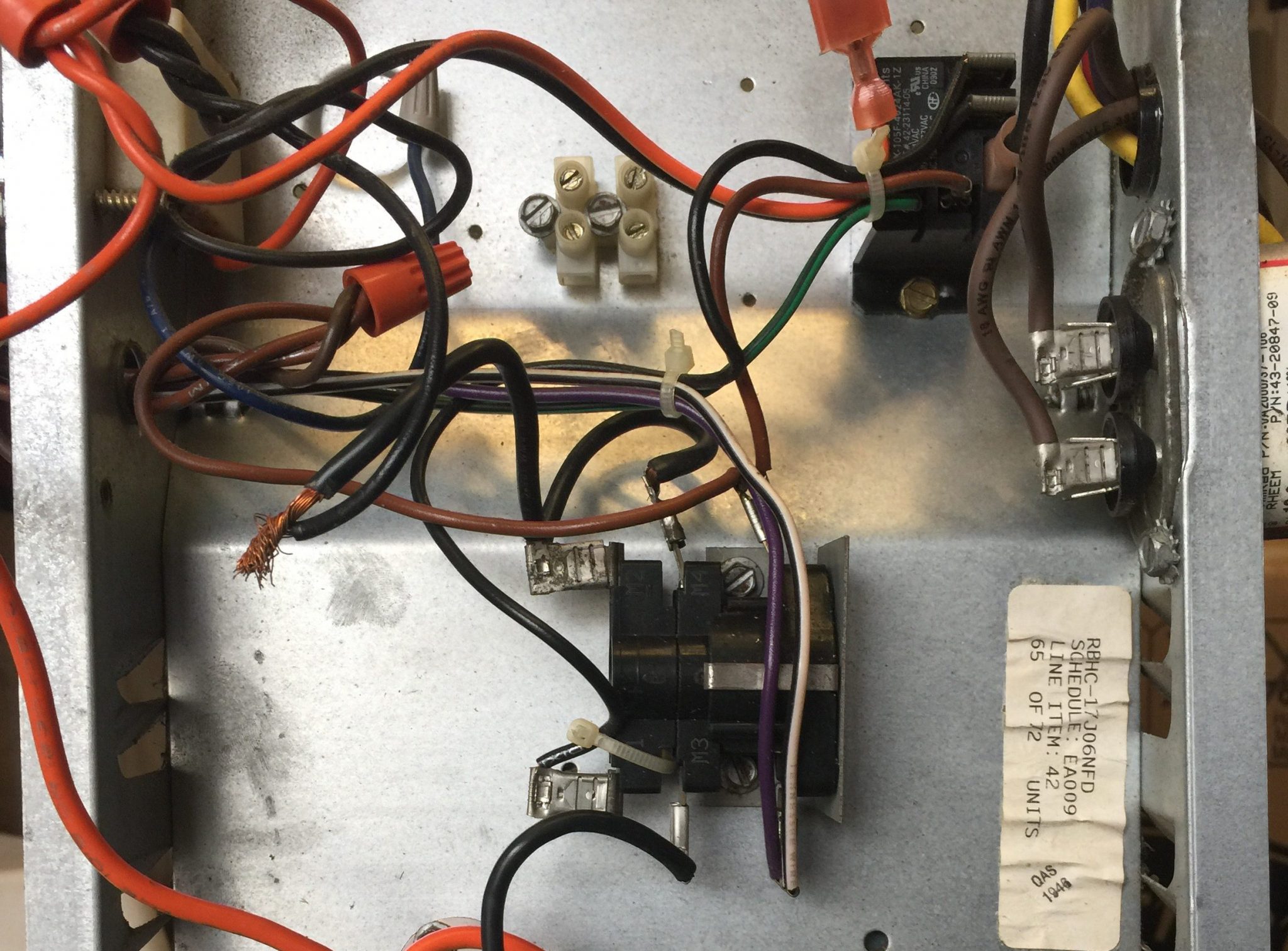

5. Incoming Power Issues: With all of the electronics in the outdoor unit, the mini-splits’ incoming power is less forgiving than their standard equipment counterparts. They are sensitive to voltage outside their specs in addition to surges. Check and see if the manufacturer has a recommended surge suppressor. Corrections to incoming power issues and surge protection are a must. Circuit boards do not like these items, and they will not last if left uncorrected.

6. Condensate Pump Wiring: Please follow the manufacturer’s recommended wiring for the auxiliary contacts to shut down the unit in an overflow situation. Most will break the communication wire, which in most instances is fine, but some indoor units have designated terminals and a plug for condensate overflow that should be used instead. If you wire to auxiliary terminals, ensure that you change the appropriate settings in the controls so the unit will operate correctly.

7. Use Appropriate Connectors: Using wire nuts for communication lines is not the best practice for joining communication wiring together. Butt splices, bell connectors, terminal blocks, and soldered connections are better methods. The use of wire nuts is a communication problem waiting to happen, and I would not recommend using them unless you like troubleshooting communication problems.

8. Crossed Wiring/Piping: This is a pervasive issue in multi-splits. Installers, it is crucial that you color-code or mark your line sets, as it’s really easy to get them crossed up. If you happen to get them crossed up, any number of complaints can happen. The biggest one is overcooling or overheating a space. Another one could be getting a condensate fault (especially if the unit has a condensate pump), as the condensate pump is only active when the unit calls for cooling. If you suspect crossed wiring or piping, run each head individually to verify that refrigerant is flowing to the unit that you want. Pick up some phase tape from your local hardware store or electrical supply in several colors. It could save you down the road.

In closing, stick to the basics. Mini-splits aren’t as complicated as they appear to be. Remember that all circuit boards do is take inputs, apply logic, then produce an output. Remember that poor inputs will create poor output control. Those of you who are old-school programming types will remember GIGO (garbage in and garbage out). If the input from, say, a thermistor is reading incorrectly, the output it’s responsible for controlling (EEV) will not modulate or control correctly.

P.S. – If you're new to mini-splits want to read about cleaning them, please check out this article.

Comments

Very good article, Ryan, thanks for taking the time to write it. I did want to point out that you refer to the inverter’s “heat sync”, but the correct spelling is sink, not sync. The heat is not synchronized to anything – the heat sink is “draining away” heat from the active devices (semiconductor) that perform the electronic switching action. Thanks again for a very informative article.

Very good article, Ryan, thanks for taking the time to write it. I did want to point out that you refer to the inverter’s “heat sync”, but the correct spelling is sink, not sync. The heat is not synchronized to anything – the heat sink is “draining away” heat from the active devices (semiconductor) that perform the electronic switching action. Thanks again for a very informative article.

https://tadalmed.shop/# Cialis sans ordonnance 24h

https://tadalmed.shop/# Cialis sans ordonnance 24h

trouver un mГ©dicament en pharmacie pharmacies en ligne certifiГ©es or Pharmacie sans ordonnance

https://www.google.ne/url?sa=t&url=https://pharmafst.com acheter mГ©dicament en ligne sans ordonnance

[url=https://maps.google.dm/url?q=https://pharmafst.com]Pharmacie Internationale en ligne[/url] pharmacies en ligne certifiГ©es and [url=https://www.support-groups.org/memberlist.php?mode=viewprofile&u=359970]Pharmacie sans ordonnance[/url] pharmacie en ligne

trouver un mГ©dicament en pharmacie pharmacies en ligne certifiГ©es or Pharmacie sans ordonnance

https://www.google.ne/url?sa=t&url=https://pharmafst.com acheter mГ©dicament en ligne sans ordonnance

[url=https://maps.google.dm/url?q=https://pharmafst.com]Pharmacie Internationale en ligne[/url] pharmacies en ligne certifiГ©es and [url=https://www.support-groups.org/memberlist.php?mode=viewprofile&u=359970]Pharmacie sans ordonnance[/url] pharmacie en ligne

kamagra gel: achat kamagra – Kamagra Commander maintenant

kamagra gel: achat kamagra – Kamagra Commander maintenant

kamagra pas cher acheter kamagra site fiable or achat kamagra

http://www.torremarmores.com/en/gallery2/main.php?g2_view=core.UserAdmin&g2_subView=core.UserLogin&g2_return=https://kamagraprix.shop Acheter Kamagra site fiable

[url=https://mclast.de/redirect/?url=http://kamagraprix.shop]achat kamagra[/url] kamagra en ligne and [url=https://17lubbs.com/space-uid-66189.html]achat kamagra[/url] kamagra gel

kamagra pas cher acheter kamagra site fiable or achat kamagra

http://www.torremarmores.com/en/gallery2/main.php?g2_view=core.UserAdmin&g2_subView=core.UserLogin&g2_return=https://kamagraprix.shop Acheter Kamagra site fiable

[url=https://mclast.de/redirect/?url=http://kamagraprix.shop]achat kamagra[/url] kamagra en ligne and [url=https://17lubbs.com/space-uid-66189.html]achat kamagra[/url] kamagra gel

casino olympe: olympe casino cresus – olympe casino avis

casino olympe: olympe casino cresus – olympe casino avis

On this platform, you can find a great variety of online slots from top providers.

Players can experience classic slots as well as feature-packed games with stunning graphics and exciting features.

Whether you’re a beginner or a casino enthusiast, there’s a game that fits your style.

casino

The games are instantly accessible anytime and optimized for laptops and tablets alike.

You don’t need to install anything, so you can get started without hassle.

Site navigation is intuitive, making it convenient to browse the collection.

Sign up today, and discover the excitement of spinning reels!

On this platform, you can find a great variety of online slots from top providers.

Players can experience classic slots as well as feature-packed games with stunning graphics and exciting features.

Whether you’re a beginner or a casino enthusiast, there’s a game that fits your style.

casino

The games are instantly accessible anytime and optimized for laptops and tablets alike.

You don’t need to install anything, so you can get started without hassle.

Site navigation is intuitive, making it convenient to browse the collection.

Sign up today, and discover the excitement of spinning reels!

On this platform, you can discover a great variety of casino slots from leading developers.

Visitors can experience traditional machines as well as modern video slots with stunning graphics and exciting features.

Even if you’re new or an experienced player, there’s something for everyone.

casino games

Each title are instantly accessible anytime and designed for PCs and mobile devices alike.

No download is required, so you can start playing instantly.

The interface is intuitive, making it simple to find your favorite slot.

Join the fun, and dive into the excitement of spinning reels!

On this platform, you can discover a great variety of casino slots from leading developers.

Visitors can experience traditional machines as well as modern video slots with stunning graphics and exciting features.

Even if you’re new or an experienced player, there’s something for everyone.

casino games

Each title are instantly accessible anytime and designed for PCs and mobile devices alike.

No download is required, so you can start playing instantly.

The interface is intuitive, making it simple to find your favorite slot.

Join the fun, and dive into the excitement of spinning reels!

Good morning. I want to thank you for all the effort and work you put into providing FREE education. The information is always thorough without feeling like I’m reading out of a book. Coming into the trades with no background experience at all this is all very helpful as a student. Thank you!

Good morning. I want to thank you for all the effort and work you put into providing FREE education. The information is always thorough without feeling like I’m reading out of a book. Coming into the trades with no background experience at all this is all very helpful as a student. Thank you!

Great article. One addition to the list for number 3 refrigerant leaks would be line set corrosion due to faulty insulation manufacturing. This is a real problem for Mini splits and will soil there reputation if not corrected properly.

Great article. One addition to the list for number 3 refrigerant leaks would be line set corrosion due to faulty insulation manufacturing. This is a real problem for Mini splits and will soil there reputation if not corrected properly.

Acheter Viagra Cialis sans ordonnance: Cialis sans ordonnance 24h – cialis generique tadalmed.shop

Acheter Viagra Cialis sans ordonnance: Cialis sans ordonnance 24h – cialis generique tadalmed.shop

To leave a comment, you need to log in.

Log In