Get Tech Tips

Subscribe to free tech tips.

Is a Smaller Suction Line OK? – Suction Line Sizing

In residential, most techs and installers size the suction (vapor) and liquid lines to the stubs on the equipment. In larger built-up systems, sizing the suction and liquid lines is rarely the responsibility of the technician.

But what happens if we show up to a job where the lines cannot be (reasonably) replaced because the size is different? Or what if the stub on the evaporator coil is a different size than the condenser?

The Factors in Suction Line Sizing

- Pressure Drop – Any pressure drop in the suction line due to size, length, or fittings results in lower refrigerant density and higher compression ratio at the compressor without a corresponding decrease in evaporator temperature. In other words, you get all the bad stuff like compressor overheating and poor capacity without a lower evaporator operating temperature. That is why pressure drops in the suction line are generally recommended to be less than 3 PSI on R22 and 5 PSI on R410, but the lower, the better.

- Oil Carry – When mineral oil was used, oil carry was a bigger deal than it is now. However, manufacturers still design the systems with a minimum suction refrigerant velocity, which means that bigger isn't better. The York/Johnson controls guide says the following:

Minimum (suction) velocity of 1000 fpm for vertical lines and 800

fpm for horizontal lines guarantee proper oil return

Equivalent Length

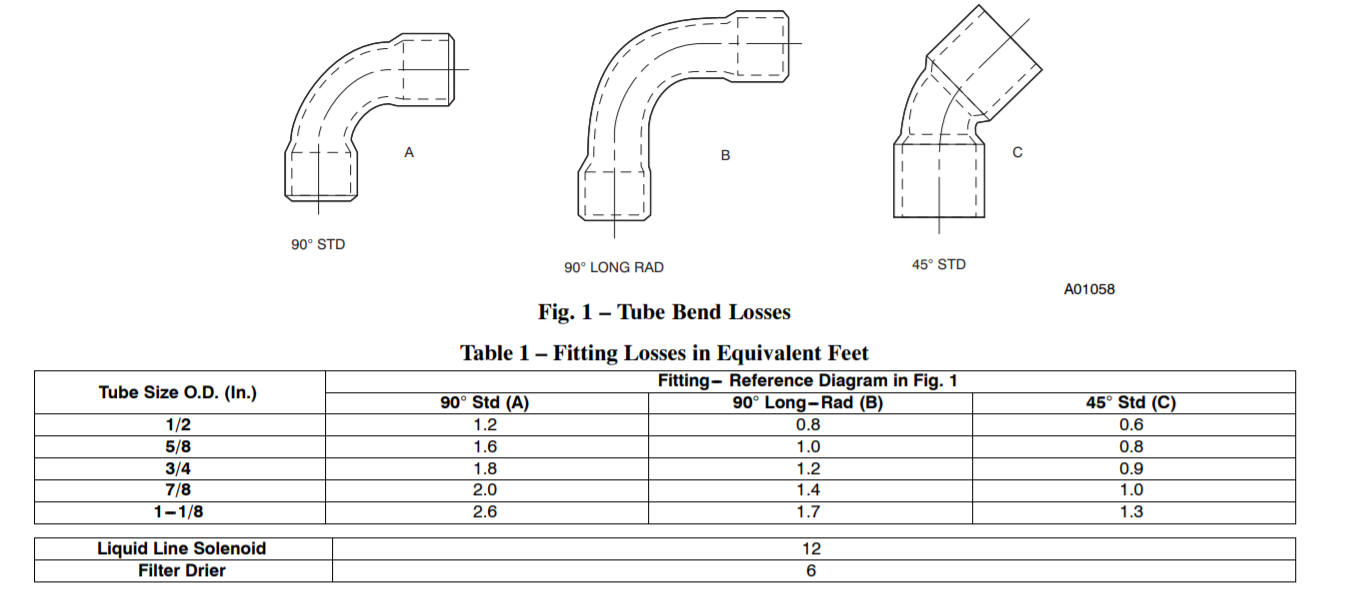

Before we look at an example of a suction line selection chart, we must first square on this topic of “equivalent” length. You need to calculate the actual line length and then add in the equivalent length of fittings (very similar to duct design). By just a quick glance at the chart above, you can see the advantage of using long-radius 90s.

Manufacturer's Chart

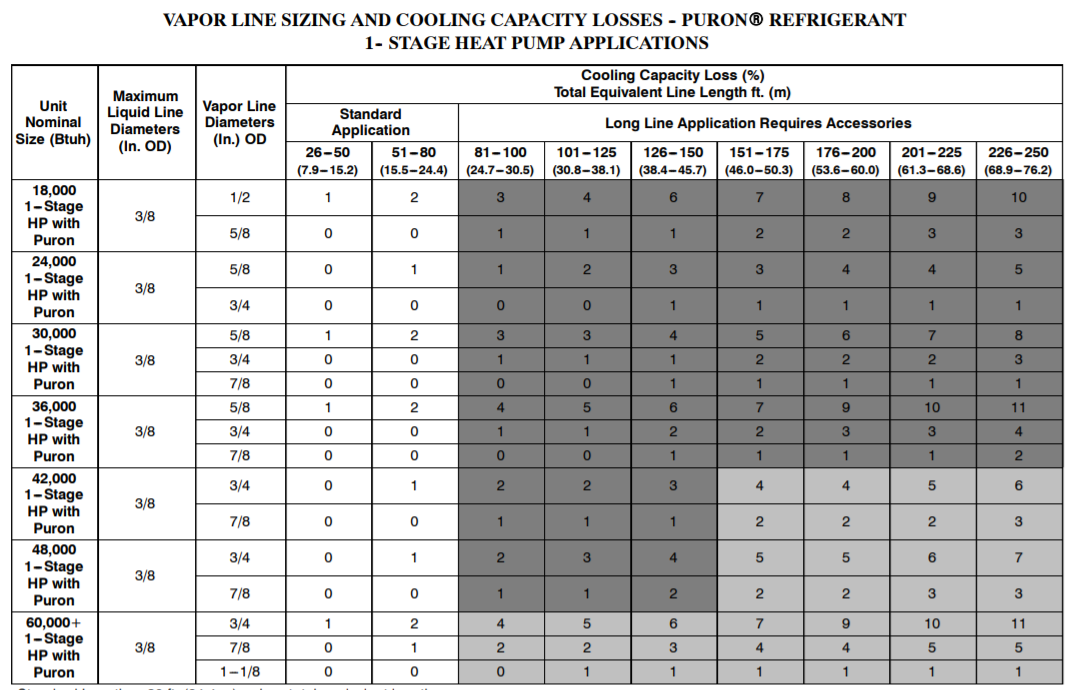

Now, it's time to look at your manufacturer's literature to see if a particular suction line size is acceptable. The one above applies to standard Carrier R-410a single-stage heat pumps and comes from the system product data.

Take a look at the 5-ton system at the bottom of the chart above. You may have thought that a 3/4″ line set could NEVER be used on a 5-ton, but this chart clearly shows that the percentage of capacity loss will only be 1% on line sets with equivalent lengths of under 50′. While this isn't ideal, it may be the only economical option in some cases. On the other hand, a 5/8″ suction line on a 3.5 ton is “off the chart,” meaning it isn't acceptable under any conditions.

Either way, our goal is to keep suction line pressure drop to a minimum while maintaining the minimum suction velocity, and this is the sweet spot manufacturers keep you in with these charts.

—Bryan

P.S. — We also have a tech tip on liquid line sizing, which you can read HERE.

Comments

To leave a comment, you need to log in.

Log In