Get Tech Tips

Subscribe to free tech tips.

Introduction to VAV Systems

If you work in large commercial offices or mixed-use buildings, you almost certainly work with VAV systems regularly. If you aren't familiar with VAV, this is a quick intro to the basics so that they won't seem so overwhelming.

VAV stands for variable air volume; this means that the AHU (air handling unit) can vary the amount of air output to suit the amount of air needed for the areas served.

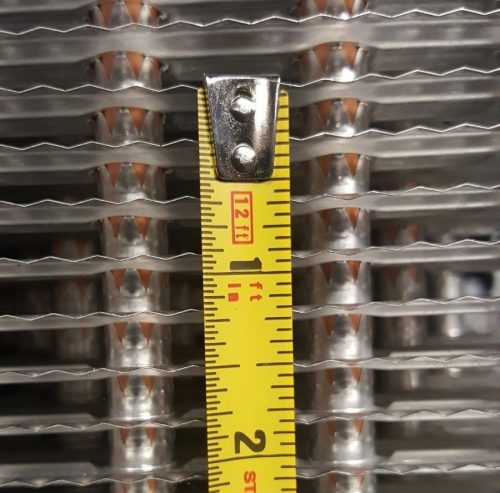

A typical configuration for VAV would be to set the blower to hit a fixed static pressure target (say, 1 to 1.2 inches of water column pressure), and the cooling capacity varies to maintain around a 55° supply air temperature.

Each zone is served by at least one VAV box—or, more accurately, a VAV terminal. The terminal is controlled by a temperature (generally the BAS system) to open and close to provide more or less air to the zone. As VAV terminals open, the static pressure in the supply duct decreases, and the blower increases air volume to maintain the static. As the air volume increases, the system cooling capacity also needs to increase to maintain the supply air temperature.

This constant modulation requires variable refrigerant capacity in the form of multi-stage or variable refrigerant compression and generally a blower fitted with a VFD (variable frequency drive). However, older VAV systems often used an adjustable vane at the blower inlet to vary the air volume.

One of my favorite YouTube channels is THE ENGINEERING MINDSET, and the video below covers VAV in more detail. You can click this LINK to watch it directly on YouTube.

Comments

To leave a comment, you need to log in.

Log In