Get Tech Tips

Subscribe to free tech tips.

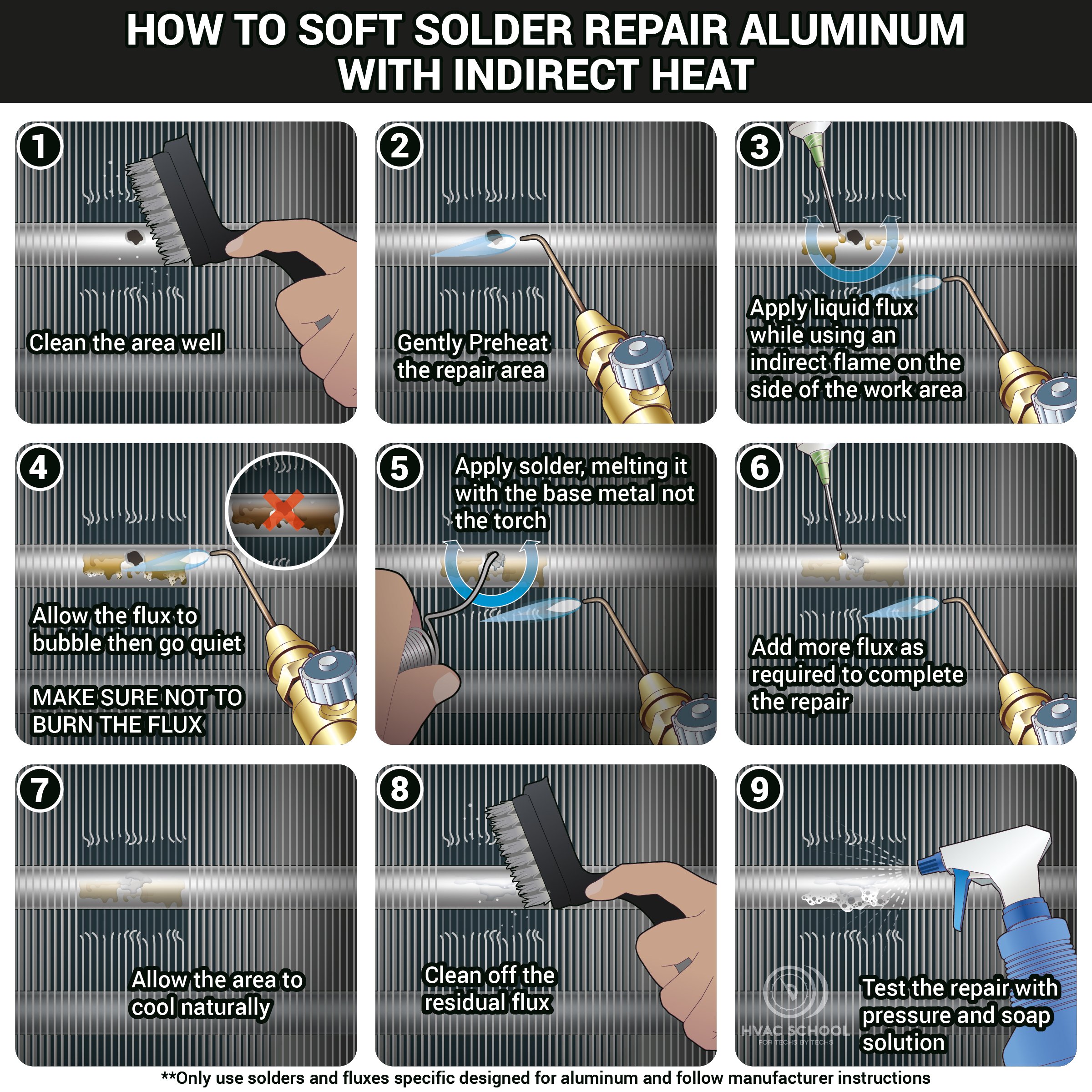

Indirect Soldering Technique

As HVAC/R techs, we don't generally do a lot of soldering—unless you are in a shop that has embraced Stay Brite® 8 from Harris. Several aluminum repair products on the market also use an indirect soldering type technique, so this is a generic overview of some best practices. As always, follow the manufacturer's instructions for the best results.

Prep the Work Area

When soldering, you will want to get everything as clean as possible before you start. You can begin with brushes or Emory cloth to get the big stuff off. Then, use alcohol and a lint-free cloth at the end to get off any residue or silica particles. Just make sure any alcohol is completely evaporated before using a torch.

Another nice trick for tight work on aluminum coils is using a wire wheel on a Dremel to get the area clean. I had luck with this when repairing a microchannel coil.

Use Lower Heat Than Brazing

Often soldering is best done with an air-acetylene or MAPP gas torch rather than a typical oxygen rig, especially when you have room to work. If you are working in a tight space, you may opt for a small oxy/acetylene tip like the one shown above, but be VERY careful. The flame may be small, therefore putting out fewer BTUs than a larger flame, but it will still be a much hotter temperature than air-acetylene or MAPP.

Work Indirectly

When working with solders or lower-temperature base metals like aluminum, it is generally best to heat around the repair or joining area with your torch rather than right on it. The goal of indirect soldering is to allow the heat to gently conduct into the area, ESPECIALLY when working with the hotter oxygen flame. With brazing, we can almost put the heat directly on the rod as we work, but that won't work at all for most of these products.

Watch the Flux

Flux not only acts to keep oxides away from the work area but also gives us a visual indication of when the work area is at the right temperature to apply solder. If we underheat the work area, the solder won't flow into the joint. If we overheat the work area, we will burn the flux, and the solder won't flow into the joint.

Another note on flux is that we only want to apply it to the male end when joining. We don't want to overuse flux and contaminate the system. Many fluxes are corrosive, so wipe all the flux off once the joint cools to prevent leaks.

—Bryan

P.S. — We have a video showing how to patch an aluminum coil. You can watch it HERE.

Comments

To leave a comment, you need to log in.

Log In