Get Tech Tips

Subscribe to free tech tips.

How to Use a Manufacturer Fan Table and Why They are Important

Many installers and service technicians know how to read and use a manufacturer fan table, but this is a quick review with a few extra tips for newer techs. It’s also a good reminder to senior technicians about how this easy-to-use practice can also be easily abused.

At installation, properly setting up airflow is imperative to the performance and longevity of the appliance. A practical way to do this is utilizing the manufacturer-supplied fan tables found in every installation manual. Here’s a review on how to set up airflow on a new system:

- Determine your target airflow. (The national average is 400 cfm/ton. However, in a dry climate, design airflow could be 450-500 cfm/ton, and in a humid climate, airflow is typically designed at 350-300 cfm/ton.)

- Set your fan speed (choose the speed tap, or set the dip switches).

- Verify that the equipment and ductwork are clean and all packing materials are removed from inside the appliance. (Yes, technicians miss that sometimes.)

- Run the system to achieve the test conditions in which the fan table was created. (Fan table airflow readings are only valid if the field conditions match as closely to the lab conditions as possible, i.e., wet coil, dry coil, with or without heat strip kits, etc.)

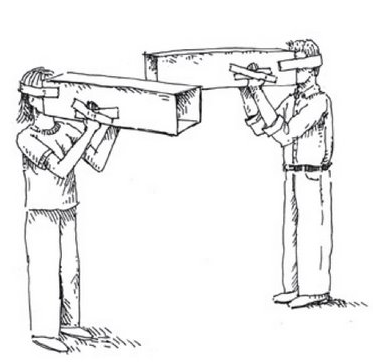

- Measure total external static pressure (see how to measure TESP below; you can also watch this video.)

- On the fan table, find the model matching the equipment you have and locate the speed tap being used.

- Match the real-time static pressure with the fan table.

- The point at which both the TESP column and Speed Tap row meet is the corresponding estimated airflow.

- Make any adjustments to ductwork or fan speed to achieve the target airflow. (This is made easy if ductwork is slightly oversized and installed with manual dampers on the supply.)

For servicing, techs may use the fan table method as a quick and dirty way of verifying airflow without extensive and time-consuming testing. This can be acceptable but only if the following conditions are met:

- The equipment and ductwork are clean. (This includes making sure the filter has been replaced.)

- The equipment has been benchmarked once before. (Without a reference, the fan table cannot be relied upon as an accurate representation of estimated airflow.)

- The equipment is running as close to the documented lab conditions as possible. (But even then, how wet is “wet?”)

Static pressure readings stand alone as a valuable measurement during a service call, and TESP can inform a technician whether more extensive testing is required. But if you have never worked on the equipment, or your company did not install the equipment, the fan tables will not be useful until full-system commissioning has been completed.

Carrier FB4CNF Installation Manual

Another important tip is to keep the return static pressure below 0.4” w.c. at all times. According to many manufacturers’ literature, a return static pressure of 0.4’ w.c. or higher can potentially result in water from the primary drain pan being picked up and thrown around inside the cabinet area, sometimes into the ductwork.

It is important to understand static pressure measurement is NOT a measurement of airflow—this is where many technicians abuse this method. Static pressure is exactly what it says: a measurement of pressure in reference to the space outside the ductwork. Based on lab testing conditions, a manufacturer can determine the airflow of a system under a known resistance. Static pressure is used as a proxy to estimate airflow, but this method is only as good as the conditions in which it is applied. Static pressure readings are air density-dependent, so zeroing a manometer in a cold, dry attic and then inserting the probes into a humidified, warm duct system will adversely affect the accuracy of your measurements. This method is also heavily dependent on how detailed the manufacturer's fan table is. An example of a good fan table would list the following:

- Equipment model

- If the unit was tested under wet or dry conditions

- If heat strips were installed during testing

- Any corresponding wattage/rpm determinations under given conditions

Carrier FB4CNF Installation Manual

The difficulty with using fan tables as a way to measure airflow is realizing that the resistance across the equipment is dynamic and will likely change many times over the course of a test (the coil may get wetter as it is loaded with latent heat, the coil will become dirty over time, etc.). Measuring actual airflow is difficult to do, but static pressure measurements are still very valuable and are a good way to determine if a problem exists and on which side of the ductwork it exists (supply or return).

A great product for measuring airflow in the field is the TrueFlow Grid by The Energy Conservatory. For more information on airflow and airflow Measurements, TruTechTools has an entire section of literature and webinars on the topic. Here is a video we recorded for them in 2017 regarding static pressure and fan tables:

—Kaleb

Comments

To leave a comment, you need to log in.

Log In