Get Tech Tips

Subscribe to free tech tips.

How I Failed to Re-diagnose: The Lesson I Learned

This is the tale of how I found myself stuck on a service call for over 12 hours on a weekend due to my failure to re-diagnose an issue. I was working for a service company that had many accounts with local gas stations. These were large customers, and we did everything we could to keep them happy.

One Friday, as I was gearing up for my on-call weekend, I was informed I must travel an hour and a half away early the next morning to a gas station where another technician had diagnosed a faulty X-13 blower motor. The technician didn’t have the right blower motor for the repair, so the system was still down. Here was the catch: no one knew what size blower motor was supposed to go in. No model numbers, no detailed notes, nothing. So, I grab every size aftermarket X-13 motor I could find in the shop. I had up to ¾ HP.

I arrived to find this location had two 5-ton package units mounted atop stands lifted 8 feet off the ground. After I set up the ladder and double-checked the motor size, I realized it was 1 HP. I began calling all the parts houses in the area, hoping someone answered at 8 am on a Saturday. No luck. I called parts houses in my local area and my co-workers to try and find a 1 HP X-13 motor that would work. Finally, I got in touch with one of my local suppliers. He had a motor that would fit the system I was working on, but he was an hour away from the supply house, and I was an additional hour and a half away. Luckily, my employer at the time picked it up for me, and I had the part within a couple of hours. I still had not re-diagnosed the system at that time.

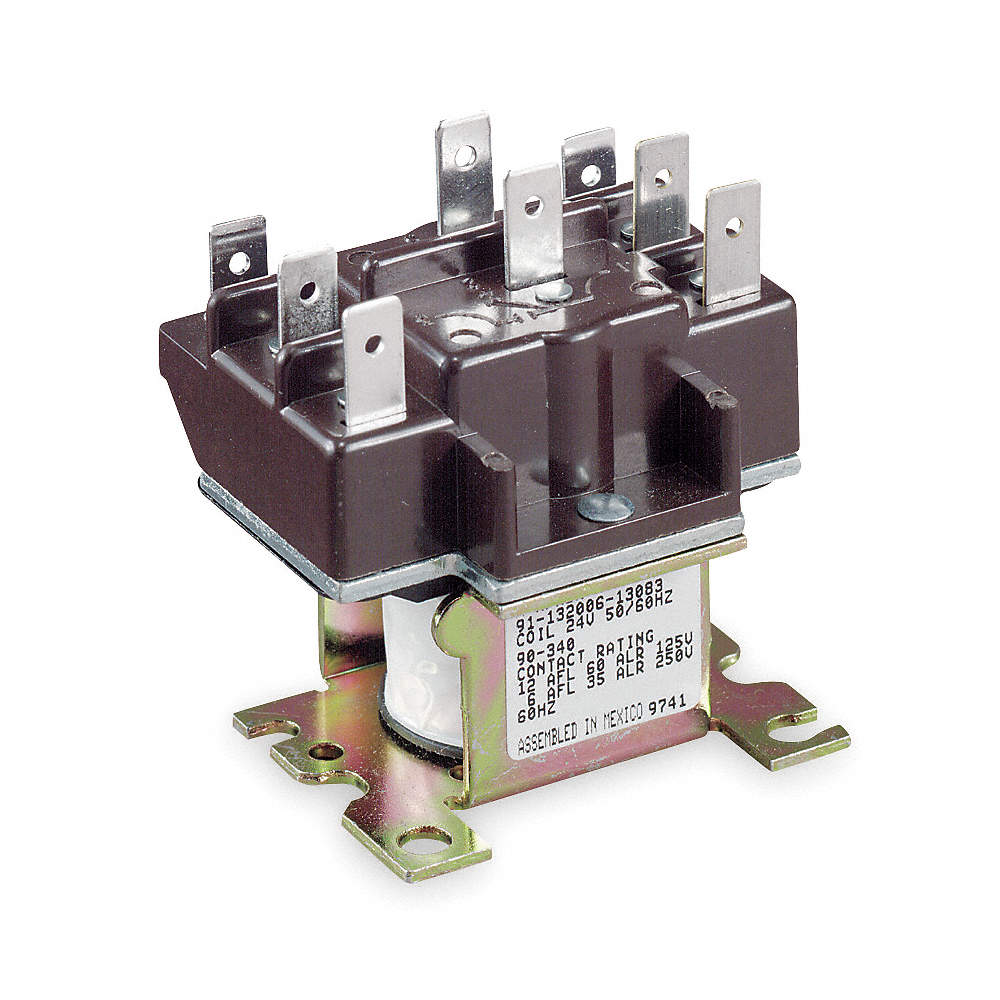

Once I had the motor in hand, I quickly replaced it and had everything back together in a snap. I re-energized the system, and—I cursed loudly. The motor wouldn’t run. NOW I start re-diagnosing, a step I should have taken when I first arrived. As it turns out, the original motor was just fine. The motor was not receiving 24v to the motor module due to a faulty fan relay. I swapped out the 90-340 relay in the electrical compartment, restarted the system, and the blower ran beautifully. I hated myself.

I entertained the idea of packing up, walking away, and calling it complete, but I knew too well how that plays out. I began running complete system diagnostics and found the system charge to be very low. I started leak-searching the system with Big BluⓇ from Refrigeration Technologies and discovered a micro leak on the mechanical connection between the distributor tube and the TXV. No rubouts were apparent, and it wasn’t a super loose connection, but it was clearly leaking. This was a package unit, remember, so I had to recover the entire system charge before making any repairs.

Once recovered, I found out that the connection was just coming loose. A healthy dab of NylogⓇ on the fitting connection and a torque wrench was all I needed to pass a nitrogen pressure test. Of course, the repair process was time-consuming, but I eventually had the system evacuated, cleaned, recharged, and operating in peak condition under the current load.

I still would have needed to make the leak repair no matter what, but I could have easily saved 3.5 hours if I had re-diagnosed the system first when I arrived at the job. One could argue I was simply distracted by the chaos of the call, which would be true. However, a good technician should be able to follow the proper processes despite disorganization and frustration. I learned the importance of always checking behind yourself and others when you arrive to make a repair. Since then, I have found the real causes of issues previously diagnosed as bad TXVs, reversing valves, motors, etc. (either by another technician or me).

ALWAYS double-check your work and other people’s work. You never know how valuable it is until you fail to do it, and it costs you time and money.

—Kaleb

Comments

To leave a comment, you need to log in.

Log In