Get Tech Tips

Subscribe to free tech tips.

Fan Blade Shroud Depth

When a system has abnormally high head pressure (high condensing temperature over ambient) and compression ratio, one of the easiest things to look for is a dirty condenser coil. More often than not, that will be the cause.

However…

There is another category of issues that can cause high condensing temperature (high head pressure), but these result from improper practices rather than dirt and grime.

When a tech comes across a failed condensing fan motor or a damaged blade, they will often go to their van and see what they have as a “universal” replacement part. I don't have an issue with using aftermarket repair parts in some cases, but you need to make sure that the part you are using will operate properly without sacrificing capacity, efficiency, and longevity.

Often, when using aftermarket parts, a tech may be sacrificing one or more of these things. That can lead to issues.

When replacing a fan blade, you need to ensure:

- The pitch is a match

- The number of blades is a match

- The diameter is a match

If you change the pitch, you will also need to change the number of blades and vice versa to end up with the same CFM airflow output, which can be very tough to determine in the field.

The diameter really cannot change, or you won't have the proper gap between the blade edge and the shroud (usually 1/2-1″), which can greatly impact air movement.

When replacing a motor, you need to ensure:

- The RPM (number of poles) matches

- Voltage and phasing matches

- The HP is the same or greater

- The physical size will allow proper installation

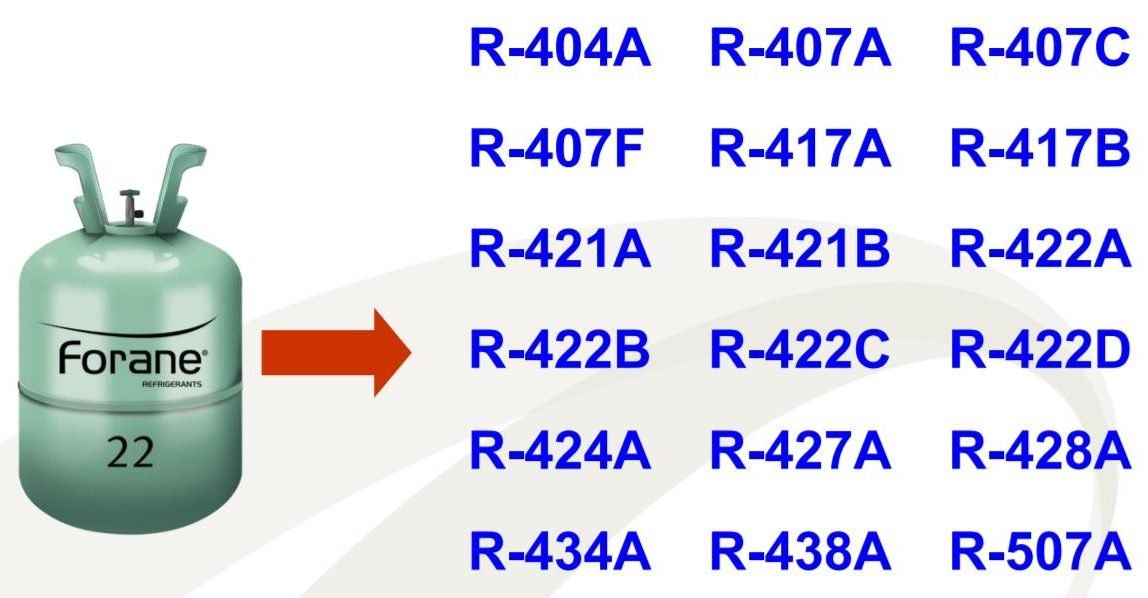

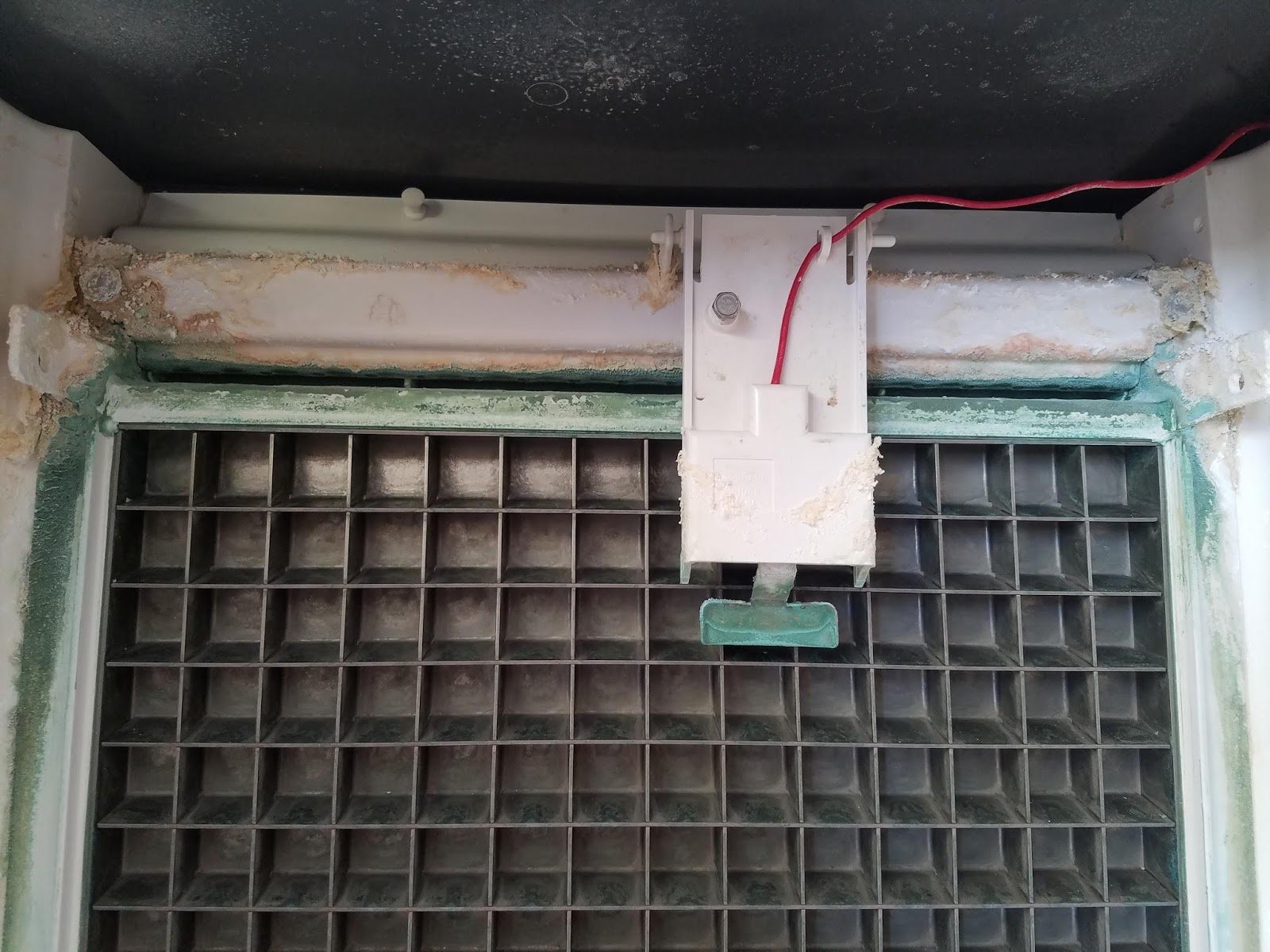

In some cases, the technical specs may work, but the motor body may be deeper. When this happens, you need to make sure that the fan blade can still sit high enough in the fan shroud for proper air movement. In many cases, the blade and shroud are designed to match the middle/center of the blade with the bottom of the fan shroud (cowling). If these don't match, airflow can decrease.

This issue often comes into play when a factory motor fails on smaller tonnage residential units with a less than 1/4-HP motor. In these cases, when you replace the factory motor with a universal motor, the larger physical depth of the motor and sometimes the width can result in less than designed airflow. When replacing the motor, ensure that you can still place the motor blade in the same position in relation to the blade to ensure proper airflow/condensing temperature.

Sometimes, you will come across systems that run higher head pressure than they should be. In these cases, you will want to check and make sure the motor HP and RPM are correct and that the blade is properly sized and positioned in the shroud.

As always, attentiveness is the key to finding issues, even issues caused by others.

—Bryan

P.S. – We've also written an article that contains some more considerations and the steps for condenser fan motor replacement. You can read that article HERE.

Comments

Fan depth is important. Replacing a 1/5 HP fan motor with a 1/3 HP permanently is going to change the fan depth permanently.

Fan depth is important. Replacing a 1/5 HP fan motor with a 1/3 HP permanently is going to change the fan depth permanently.

This was so much more than I expected. Thank you for going beyond the surface and offering something truly valuable.

This was so much more than I expected. Thank you for going beyond the surface and offering something truly valuable.

Your writing doesn’t try to impress; it connects. That’s why it resonates so deeply with so many people.

Your writing doesn’t try to impress; it connects. That’s why it resonates so deeply with so many people.

I am really grateful to the owner of this site who has shared this impressive paragraph at at this time.

I am really grateful to the owner of this site who has shared this impressive paragraph at at this time.

My condenser went out so I had the AC tech replace with an upgraded fan motor and blade. He left so I went outside to inspect the work.

Turned out the new blade was too low and was below the shroud. I reached in my wallet, pulled out a dollar bill, laid it on the top of the outlet and it didn’t blow off! Learned that trick years ago. It just sucked it down onto the exhaust cover. What to do now? Not spending any more money so I thought I would extend the shroud down about 2 inches with some sheet metal. Any other suggestions?

My condenser went out so I had the AC tech replace with an upgraded fan motor and blade. He left so I went outside to inspect the work.

Turned out the new blade was too low and was below the shroud. I reached in my wallet, pulled out a dollar bill, laid it on the top of the outlet and it didn’t blow off! Learned that trick years ago. It just sucked it down onto the exhaust cover. What to do now? Not spending any more money so I thought I would extend the shroud down about 2 inches with some sheet metal. Any other suggestions?

I would call the company back out. Typically you can adjust the fan blade. It sounds like it may actually be rotating the wrong direction which can be fixed by switching a few wires.

I would call the company back out. Typically you can adjust the fan blade. It sounds like it may actually be rotating the wrong direction which can be fixed by switching a few wires.

To leave a comment, you need to log in.

Log In