Get Tech Tips

Subscribe to free tech tips.

ECM, VFD, and Inverter – What’s the Difference?

Ever since Nikola Tesla invented the modern induction motor, we have been struggling with varying the speed of motors efficiently and reliably. The trouble in the HVAC industry is that there are several different types of technologies in play, and they can easily get confused.

ECM (Electronically Commutated Motor)

In residential and light commercial HVAC, we have seen ECM (Variable-Speed/X13) motors for years, primarily in blower motors but sometimes even in condenser fan motors. The first thing to know is that an ECM motor is a “Brushless” DC (direct current) motor. Most traditional DC motors require brushes to provide power to the motor rotor (spinning part). Brushes are notorious for wearing out over time, making DC motors unreliable in constant-duty applications. An ECM motor uses a permanent magnet rotor, eliminating the need for power to be fed to the rotor through brushes.

An ECM motor is a DC three-phase motor with a permanent magnet rotor and a motor module that controls the cycle rate. Here is a great video on how they work:

VFD (Variable Frequency Drive)

For existing AC (alternating current) three-phase motors, the only way to change the speed reliably and efficiently is to alter the “frequency” of the power applied to the motor to something other than 60 Hz (60 cycles per second). A VFD intercepts the power applied to a motor and changes it to DC power with a bank of diodes (rectifier), also called a converter. It then smooths out the power using capacitors before feeding that power to a bank of transistors called an inverter, which constantly switches the power from DC back to a form of power called PWM (pulse width modulation).

PWM replicates the frequency change to the motor. The drive needs to provide this PWM power at the correct voltage and current to control a three-phase motor properly.

Inverter/Inverter Drive

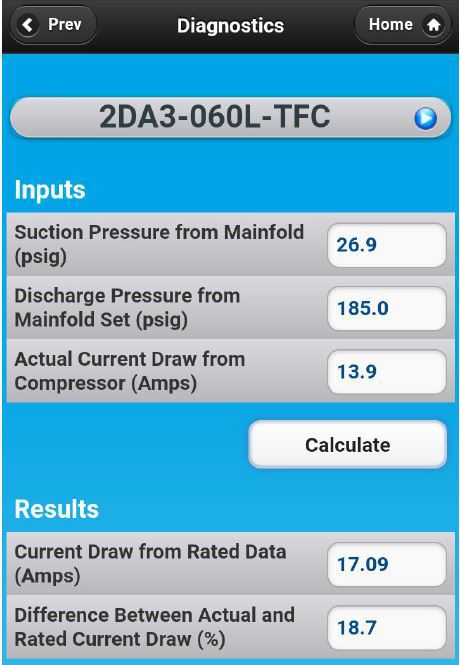

Many A/C systems come with converters, capacitor smoothing (intermediate circuit), and the inverter built into the equipment itself to drive a compressor or compressors. This inverter technology is essentially an intelligent and specifically designed VFD built into the equipment itself. The Carrier Infinity system is one of many systems that utilize inverters.

These technologies are constantly evolving and changing, and while they may be similar, the different names describe different types and applications of technology. All of these are designed with the end goal of making motors go more than one speed with the best efficiency and reliability.

—Bryan

P.S. – We hosted livestream about VFDs and inverters with Matthew Taylor and Corey Cruz. You can watch it on our YouTube channel HERE, especially if you're interested in the topic from a commercial refrigeration perspective.

Comments

I love getting the tips of the day. Keep them coming. Im just beginning in the field and it really helps me.

I love getting the tips of the day. Keep them coming. Im just beginning in the field and it really helps me.

This flight-themed slot blends exploration with high stakes.

Jump into the cockpit and spin through aerial challenges for massive payouts.

With its classic-inspired graphics, the game captures the spirit of pioneering pilots.

play aviator game download

Watch as the plane takes off – cash out before it flies away to grab your earnings.

Featuring seamless gameplay and immersive sound effects, it’s a must-try for casual players.

Whether you’re chasing wins, Aviator delivers endless excitement with every spin.

This flight-themed slot blends exploration with high stakes.

Jump into the cockpit and spin through aerial challenges for massive payouts.

With its classic-inspired graphics, the game captures the spirit of pioneering pilots.

play aviator game download

Watch as the plane takes off – cash out before it flies away to grab your earnings.

Featuring seamless gameplay and immersive sound effects, it’s a must-try for casual players.

Whether you’re chasing wins, Aviator delivers endless excitement with every spin.

I’ve been exploring terpene-based products https://www.terpenewarehouse.com/collections/energy-terpenes recently, and I’m indeed enjoying the experience. The scents are with, natural, and pleasant. They add a gracious drink to my constantly programmed, dollop congeal the atmosphere and atmosphere. A massive find for anyone who appreciates pungent wellness tools.

I’ve been exploring terpene-based products https://www.terpenewarehouse.com/collections/energy-terpenes recently, and I’m indeed enjoying the experience. The scents are with, natural, and pleasant. They add a gracious drink to my constantly programmed, dollop congeal the atmosphere and atmosphere. A massive find for anyone who appreciates pungent wellness tools.

Pretty section of content. I just stumbled upon your website and in accession capital to assert that I get in fact enjoyed account your blog posts. Anyway I will be subscribing to your feeds and even I achievement you access consistently fast.

Pretty section of content. I just stumbled upon your website and in accession capital to assert that I get in fact enjoyed account your blog posts. Anyway I will be subscribing to your feeds and even I achievement you access consistently fast.

Этот сайт — цифровая витрина частного детективного агентства.

Мы предоставляем сопровождение в области розыска.

Штат сотрудников работает с максимальной конфиденциальностью.

Нам доверяют сбор информации и выявление рисков.

Заказать детектива

Каждое обращение получает персональный подход.

Опираемся на проверенные подходы и работаем строго в рамках закона.

Если вы ищете реальную помощь — вы по адресу.

Этот сайт — цифровая витрина частного детективного агентства.

Мы предоставляем сопровождение в области розыска.

Штат сотрудников работает с максимальной конфиденциальностью.

Нам доверяют сбор информации и выявление рисков.

Заказать детектива

Каждое обращение получает персональный подход.

Опираемся на проверенные подходы и работаем строго в рамках закона.

Если вы ищете реальную помощь — вы по адресу.

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/ML7420A3055-Install.pdf

Anyone have good info on these motors and how they work or similiar ?

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/ML7420A3055-Install.pdf

Anyone have good info on these motors and how they work or similiar ?

How are 3-phases of sinusoid power applied to the stator windings considered DC?

How are 3-phases of sinusoid power applied to the stator windings considered DC?

To leave a comment, you need to log in.

Log In