Get Tech Tips

Subscribe to free tech tips.

Ductless Line Sets and Corrosion

This article includes significant contributions from Neil Comparetto and Brian Chadwick, both of whom are HVAC technicians in Virginia. Brian is also the owner of Chadwick Air, and Neil is a co-owner of Comparetto Comfort Solutions and a longtime contributor to HVAC School. Thanks, guys!

DISCLAIMER: A lot of the information in this article is based on field experience and does not appear to have a peer-reviewed scientific basis. Please DON’T treat this article as a definitive source of information. It is merely a collection of experiences and possible explanations for those experiences.

Photo Credit: Brian Chadwick

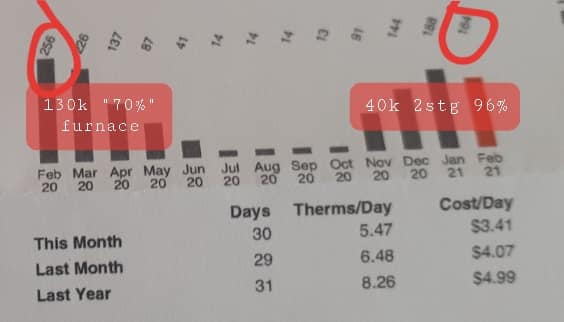

The residential HVAC technicians in our audience may be familiar with the following scenario:

You’re on a service call for a ductless system that isn’t working properly. You take your superheat and temperature readings. The system appears to be low on charge. Of course, your first step is to do leak tests around the obvious places, like connections and flare fittings, but you find nothing.

Then, you rip the white line set insulation open and see dark brown or black copper. Maybe there are even some green spots. According to the customer, the system is less than five years old. However, the copper looks like it’s well over 50 years old. Something’s not right. You perform an electronic leak test along the line—it squeals. When you do a bubble test on the copper, you see bunches of microbubbles. (Look at the image up top.)

Why the heck was that happening?

I’m sure some of you already know the answer. We knew the system leaked, but why did it happen inside the insulation? Wasn’t the insulation supposed to protect the copper from precisely that?

The short (but unsatisfying) answer is that the copper line set has corroded. The corrosion causes pinholes to appear in the copper, which is where the leaks come from. Despite being protected by fancy polyethylene (PE) sheaths, copper line sets often corrode and leak beneath the squishy barrier. Seems a bit strange, right?

The even stranger part of the situation is that several ductless systems are only a few months to a few years old when they start leaking due to corrosion. In other words, these corroded tubes aren’t ancient, so we wouldn't expect them to have leaks and corrosion. So, why is it so common? What can we do to stop it from happening?

Although there isn’t much definitive information on the causes of these issues, we’ve still noticed some trends that can help us understand and repair line set corrosion.

Sticker situation

The first clue is right on the box. Some of you may have noticed that some mini-split line set manufacturers have an interesting sticker on the box:

Photo Credit: Neil Comparetto

The stickers are yellow and tell you to seal both ends of the line set. Maybe you’ve seen a similar sticker and found it odd. Perhaps you didn’t question it at all, or maybe you haven’t come across it. Regardless, that yellow sticker is our starting point.

Why would we need to seal both ends of a line set? That’s not typical practice, so why would the manufacturer give those instructions?

Sealing the line set prevents moisture from getting in. If we look a bit at the chemical properties of PE and copper, we might be able to figure out why sealing the line sets at both ends is so important and what it has to do with corrosion.

Basic [more like acidic] chemistry

Although oxygen can pass through pure polyethylene quite easily, moisture cannot. Remember, that’s why the manufacturers recommend sealing both ends; it’s to cut off moisture’s access points. Copper cannot corrode without oxygen and moisture.

However, moisture alone doesn’t cause corrosion to the degrees that technicians have been seeing. So, there must be a reason why moisture must be kept out of the system.

There’s a theory—again, it’s just a theory—that some line set manufacturers’ white PE insulation reacts with moisture to create an acidic environment around the copper line set. Remember, you can determine if a substance is acidic based on its pH. Water is neutral and has a pH of 7. Anything with a higher pH, like soap or bleach, is basic. Anything with a lower pH, like lemon juice or vinegar, is acidic.

So, you have a clear idea of what an acidic substance is. Mild acids irritate your tongue at least a little bit, so you could probably imagine the damage that acids could inflict on copper. THAT is likely the primary source of severe corrosion, not moisture and oxygen alone.

How do we know that the insulation is the culprit?

That’s the problem. We don’t have a definitive way of knowing what the insulation contains and if it is responsible for the corrosion or not. However, one undebatable fact is that various line set manufacturers have starkly different rates of corrosion.

The purpose of this section is NOT to disparage or endorse any manufacturers. This segment is an overview of real technicians’ experiences and research on a common issue.

Brian Chadwick has seen corrosion on the bodies of quite a few PDM-brand pre-insulated line sets, but the fittings sometimes have issues as well. In those cases, the symptoms are like those of leaky flares. The image below shows an O-ring failure on a pre-insulated line set. (The original fitting was from RapidLock while the brand was still under the ZoomLock name.) A new ZoomLock fitting ended up solving that issue. Other than the line set corrosion and O-ring failures, those systems that Brian worked on had no other apparent issues.

Photo Credit: Brian Chadwick

It's worth noting, however, that PDM does not just manufacture and sell pre-insulated line sets. They also produce and sell the PE insulation itself. That means that it is possible (but not certain) that other pre-insulated copper companies may source their PE insulation from PDM. (Alternatively, PDM and other companies could possibly source their insulation from a common PE manufacturer.)

When Neil Comparetto did some investigation, he discovered that Isoclima/Isopolar line sets also had many technician reports of corrosion. Considering that some manufacturers use other companies’ parts and that Isoclima is not an American company, the quality of their copper and insulation is difficult to judge. One thing is certain, though. Many Isoclima line sets have corroded very shortly after being installed. (They corrode within months, if not straight out of the box.)

Mueller, a different manufacturer, doesn’t appear to have these corrosion problems to NEARLY the same degree as Isoclima. However, Mueller isn’t perfect; you will still likely come across line set corrosion with their PE-insulated (white) line sets.

Another potential (but not proven) risk factor for corrosion is having the insulated line set near high concentrations of VOCs (volatile organic compounds). According to an article in ACCA’s Consumer Education series, VOCs contribute to formicary corrosion in copper evaporator coils in tight, poorly ventilated homes. Many VOCs in common household products, like formic or acetic acid in cleaners or solvents, interact with moisture and oxygen to corrode copper evaporator coils. It is possible that the same principle may apply to copper line sets.

How can we know if we’re dealing with corrosion without opening the insulation?

The telltale sign of corrosion is a leak. If a system has an unexplained low charge or other problems that could be caused by leaks, you’ll want to do your typical leak test procedures. If you don’t find any leaks in the obvious locations (such as connections), then it’s likely that the leak is inside the tubing itself, and you’ll have to expose the line set.

Acid makes little pinholes in the copper inside the insulation, many of which won’t be visible to the naked eye. You may see indications of leaky areas if you open the insulation and see green spots. A greenish color indicates the most severe instances of copper corrosion (think about old pennies). However, that doesn’t mean that there will be a leak in every green spot (or that leaks won’t occur in the dark brown regions).

Electronic leak detectors can usually pick up those tiny leaks from the pinholes. Neil likes to slit the insulation jacket and run an electronic leak detector over the opening. It can usually detect a leak in the line. From there, you can expose the line set and pinpoint the leak on the line.

Of course, once you do that, you can always spray the line set with some Big Blu or other leak detection fluid. Then, you just sit back and watch for bubbles to form.

So, what can we do now?

Most of the PE-insulated line sets seem to have fundamental issues. As such, we can only do so much to reduce corrosion risks during installation or maintenance.

The best thing you can do is seal both ends of the insulation with caulk or sealant to prevent moisture from coming in. That way, moisture can't interact with the insulation and form acid inside. The sealant should be waterproof, UV-resistant, and have a strong adhesive. The yellow stickers recommend Polyken-936-30 tape. However, the adhesive isn’t usually strong enough to stop moisture and air from coming in. You’ll be better off if you try a heavier-duty caulk or sealant.

Photo Credit: Neil Comparetto

However, you can replace the line sets and use sturdier materials. Again, I should mention that this next practice is only based on personal experience and doesn’t have a scientific basis.

Some members of the HVAC School Facebook group have said that the black insulation has had far fewer leakage and corrosion problems than the white jackets. Black sheaths are made of elastomeric insulation, which is completely different from white PE jackets.

If possible, you may want to consider replacing corroded line sets with new ones and using black elastomeric insulation instead of the white PE-type. Neil has been using the Mueller Duraguard UV black line set insulation. (K-Flex is the labeled insulation manufacturer, and the insulation is branded as K-Flex Titan.)

As you can see, there isn’t a straight answer as to what is really going on with those PE-insulated line sets. Still, the trends and the collective frustration in the residential HVAC side of the industry don’t lie; there is a problem, and we’d like to find a way around it.

All we can do is be aware of the issues that certain line sets have and listen to what others in our industry have done to combat them. For now, it might just be worth your while to get your hands on a high-quality caulk or give the elastomeric black insulation a try.

Comments

Has anyone tried using the 3/8″ plastic coated copper line used for fuel oil lines. Slide insulation over that. Now the copper is isolated from the insulation. A true pain but could possibly solve the problem.

Has anyone tried using the 3/8″ plastic coated copper line used for fuel oil lines. Slide insulation over that. Now the copper is isolated from the insulation. A true pain but could possibly solve the problem.

GuiNN 204 misplaced to Cake 1.88 in my first tests under these circumstances.

GuiNN 204 misplaced to Cake 1.88 in my first tests under these circumstances.

To learn more in regards to the Wii Match, read How the Wii Works.

To learn more in regards to the Wii Match, read How the Wii Works.

November 1996-Might 2000 (first 4 volumes): The journal was revealed twice a 12 months, in November and should respectively, and every volume of the journal contained one 12 months’s November issue and the following yr’s May problem.

November 1996-Might 2000 (first 4 volumes): The journal was revealed twice a 12 months, in November and should respectively, and every volume of the journal contained one 12 months’s November issue and the following yr’s May problem.

A Administrators assembly was known as-the auditors learn the assertion-which confirmed us within the crimson greater than $400,000-a very heavy loss.

A Administrators assembly was known as-the auditors learn the assertion-which confirmed us within the crimson greater than $400,000-a very heavy loss.

As soon as your subconscious mind really does get that message you possibly can be certain it will likely be working behind the scenes consistently to ensure you receive it.

As soon as your subconscious mind really does get that message you possibly can be certain it will likely be working behind the scenes consistently to ensure you receive it.

Thanks for the nice article. I have been using a coated copper pipe (ISOTECH) that seems to work well as the metal is now isolated from the external environment. Little more expensive than the standard line sets but it seems to me to be the solution to all corrosion problems.

I have been reported by the local contractors community of issues with the elastomeric black insulation as well.

Thanks for the nice article. I have been using a coated copper pipe (ISOTECH) that seems to work well as the metal is now isolated from the external environment. Little more expensive than the standard line sets but it seems to me to be the solution to all corrosion problems.

I have been reported by the local contractors community of issues with the elastomeric black insulation as well.

Thanks for the nice article. I’ve recently came across a new coated line sets with tough jacket (ISOTECH line sets) and they seem to work well. Little premium price but nothing crazy for an unique product.

I have been educated by the local Rep on line sets leaks and it matches up with what you state din the article.

The copper pipe is coated and now isolated from the external environment so no contact with oxygen or moisture or VOCs = no corrosion! I have been reported of few new black rubber elastomeric line sets failures by the local contractors community and so I gave credit to the ISOTECH product. So far so good.

Thanks for the nice article. I’ve recently came across a new coated line sets with tough jacket (ISOTECH line sets) and they seem to work well. Little premium price but nothing crazy for an unique product.

I have been educated by the local Rep on line sets leaks and it matches up with what you state din the article.

The copper pipe is coated and now isolated from the external environment so no contact with oxygen or moisture or VOCs = no corrosion! I have been reported of few new black rubber elastomeric line sets failures by the local contractors community and so I gave credit to the ISOTECH product. So far so good.

I’m glad to have found this article and I think your on to something. I installed a DIY mini split and for the first two years it worked flawlessly. One day the evaporator coil froze up and I suspected it had a leak and it was low or out of refrigerant. I talked with the company and they said to honor the warranty I would need a tech to come out and pin point the problem and they would send the parts. Long story short, the tech didn’t appear to have any experience with mini splits so I had him write up that he couldn’t find the leak. The manufacture agreed to replace the unit. When I found your theory I went back and looked at some of the pictures I took when I disassembled the unit. Low and behold there is evidence of corrosion on the line set but it seems to be only where the line-set was pressed against the insulation. I’m happy to send you some picture if you’d like.

I’m glad to have found this article and I think your on to something. I installed a DIY mini split and for the first two years it worked flawlessly. One day the evaporator coil froze up and I suspected it had a leak and it was low or out of refrigerant. I talked with the company and they said to honor the warranty I would need a tech to come out and pin point the problem and they would send the parts. Long story short, the tech didn’t appear to have any experience with mini splits so I had him write up that he couldn’t find the leak. The manufacture agreed to replace the unit. When I found your theory I went back and looked at some of the pictures I took when I disassembled the unit. Low and behold there is evidence of corrosion on the line set but it seems to be only where the line-set was pressed against the insulation. I’m happy to send you some picture if you’d like.

Same here. Installed Mr Cool 4 zone mini split system 2 years ago. After the “DIY” couplings on one line set failed, the second leak was 2 pinhole leaks right next to each other. Definitely lots of condensation in the insulation. This theory of water + PE insulation is the best I have found. Mr Cool is a “bargain” brand” so a cheap PE and cheap copper are likely. Glad to have found the post! Now I know to get the insulation off the other lines ASAP.

Same here. Installed Mr Cool 4 zone mini split system 2 years ago. After the “DIY” couplings on one line set failed, the second leak was 2 pinhole leaks right next to each other. Definitely lots of condensation in the insulation. This theory of water + PE insulation is the best I have found. Mr Cool is a “bargain” brand” so a cheap PE and cheap copper are likely. Glad to have found the post! Now I know to get the insulation off the other lines ASAP.

I thought I was going crazy as put gauges to troubleshoot a 14 month old 3 zone that was flat. Decided the best start was to isolate each zone from condenser and test separate. Removed the white outer insulation at the condenser flares to find black brown copper.

I thought I was going crazy as put gauges to troubleshoot a 14 month old 3 zone that was flat. Decided the best start was to isolate each zone from condenser and test separate. Removed the white outer insulation at the condenser flares to find black brown copper.

This is the only article I have been able to find on this issue. My present system ran fine for 14 months only to go flat when calling for heat. After deciding to isolate each loop the first and longest tested fine at 500PSI for an hour. Second After an hour was down to 450PSI and had a slow leak. Third and shortest run started dropping as soon as I started applying N. As I peeled off the white insulation from the condenser working the 5 ft towards the under slab sleeves for this zone I found nothing but brown black and some spots where it turned green. Once I got to the entrance to the 3 inch sleeve for this zone I heard the faint hiss and began to soap what looks to be multiple pin holes in the 3/8. This was new construction tested to 500PSI and pulled down to 150 MICRON when installed. Now I’m thinking that the slow leak on zone 2 maybe up under the slab and the non leaking long run is just waiting to show up after a new charge. Not gonna go that route so it’s a day of pulling out failed line-set. One thing I did notice and will get some photos. When searching for the heavy leak I had one 3 inch spot where the white insulation was cut but didn’t have slack to splice so a piece of split black insulation was install then taped over with LS300. That one spot was nice bright copper that you would expect after a year and a half. Thank you for providing this platform and all your great YTvideos.

This is the only article I have been able to find on this issue. My present system ran fine for 14 months only to go flat when calling for heat. After deciding to isolate each loop the first and longest tested fine at 500PSI for an hour. Second After an hour was down to 450PSI and had a slow leak. Third and shortest run started dropping as soon as I started applying N. As I peeled off the white insulation from the condenser working the 5 ft towards the under slab sleeves for this zone I found nothing but brown black and some spots where it turned green. Once I got to the entrance to the 3 inch sleeve for this zone I heard the faint hiss and began to soap what looks to be multiple pin holes in the 3/8. This was new construction tested to 500PSI and pulled down to 150 MICRON when installed. Now I’m thinking that the slow leak on zone 2 maybe up under the slab and the non leaking long run is just waiting to show up after a new charge. Not gonna go that route so it’s a day of pulling out failed line-set. One thing I did notice and will get some photos. When searching for the heavy leak I had one 3 inch spot where the white insulation was cut but didn’t have slack to splice so a piece of split black insulation was install then taped over with LS300. That one spot was nice bright copper that you would expect after a year and a half. Thank you for providing this platform and all your great YTvideos.

Found the same on my 3 zone system. Pulled first 35 ft on shortest zone only to find pin holes every where. Now another 160 plus ft to pull out. I’m not leaving any in there even if its not leaking now.

Found the same on my 3 zone system. Pulled first 35 ft on shortest zone only to find pin holes every where. Now another 160 plus ft to pull out. I’m not leaving any in there even if its not leaking now.

thanks for the nice article we have seen this on a big job with a couple of 100 units its real disaster,, as we can see again and again quailty not cost it pays the bigest challenge is to get the customer agreeing to it

thanks for the nice article we have seen this on a big job with a couple of 100 units its real disaster,, as we can see again and again quailty not cost it pays the bigest challenge is to get the customer agreeing to it

Great discussion! Recent white insulation deterioration that seems to be clearly due to formicary corrosion . Lines were never taped pursuant to ASTM instructions and Mitsubishi requirements and ends never sealed to avoid moisture and oxygen intrusion. Some pinholes are evident on areas of pipe that are visible. Knowing that those pinholes are likely to be the external manifestation of interior copper line corrosion, can replacement of deteriorated insulation and taping & end-sealing alone abate further copper corrosion or should linesets be replaced entirely?

Great discussion! Recent white insulation deterioration that seems to be clearly due to formicary corrosion . Lines were never taped pursuant to ASTM instructions and Mitsubishi requirements and ends never sealed to avoid moisture and oxygen intrusion. Some pinholes are evident on areas of pipe that are visible. Knowing that those pinholes are likely to be the external manifestation of interior copper line corrosion, can replacement of deteriorated insulation and taping & end-sealing alone abate further copper corrosion or should linesets be replaced entirely?

If you believe that the problem is from not being taped and sealed from moisture then how do you propose to remove all the moisture from the air inside the ISO polar foam. Is there a new vacuum pump to evacuate the insulation. I swapped out all my fail line set with good ole elastomeric. Iv’e seen 20 plus year copper with elastomeric still working fine.

If you believe that the problem is from not being taped and sealed from moisture then how do you propose to remove all the moisture from the air inside the ISO polar foam. Is there a new vacuum pump to evacuate the insulation. I swapped out all my fail line set with good ole elastomeric. Iv’e seen 20 plus year copper with elastomeric still working fine.

We use these Duraguard UV-resistant Mueller line sets for mini splits

https://www.bakerdist.com/streamline-40620250b6c-1-4in-od-x-3-8in-od-1-2in-x-25ft-mini-split-lines-plain-end–90fab8f

We use these Duraguard UV-resistant Mueller line sets for mini splits

https://www.bakerdist.com/streamline-40620250b6c-1-4in-od-x-3-8in-od-1-2in-x-25ft-mini-split-lines-plain-end–90fab8f

We had to replace over a hundred defective linesets on mini-splits. The manufacturer is doing damage control saying the ends should be sealed.

Even the vendor said this is B.S.

Been doing HVAC for 40 years. Never sealed a lineset ever and never an issue till started using this crap.

There should be a class action suit here.

We had to replace over a hundred defective linesets on mini-splits. The manufacturer is doing damage control saying the ends should be sealed.

Even the vendor said this is B.S.

Been doing HVAC for 40 years. Never sealed a lineset ever and never an issue till started using this crap.

There should be a class action suit here.

I am curious about the black insulation lineset corrosion, if it is on heat pumps only or air conditioners too?

I am curious about the black insulation lineset corrosion, if it is on heat pumps only or air conditioners too?

Does black insulation lineset corrosion happen not only on the heat pumps, but air conditioners as well?

Does black insulation lineset corrosion happen not only on the heat pumps, but air conditioners as well?

Do you have any knowledge about formicary corrosion contaminating the refrigerant with acids?

Do you have any knowledge about formicary corrosion contaminating the refrigerant with acids?

This was never a big problem until manufactures started with the pre plastic co-extruded lieset coverings now they keep saying they fixed the problem but had leaks in new linesets in just 6 months and yes ends were sealed , simple solution stop using pre coextruded lineset

This was never a big problem until manufactures started with the pre plastic co-extruded lieset coverings now they keep saying they fixed the problem but had leaks in new linesets in just 6 months and yes ends were sealed , simple solution stop using pre coextruded lineset

Update: After pulling new Mueller with elastomeric insulation over a year ago copper still looks clean and system is running great. Luckily System used PVE oil so after pulling it down many times over 5 days with quite a few pump oil changes I was able to finally get it to hold below 500 Micron over night. Imagine how many consumers will blame the ductless technology when it’s really just poor quality control on behalf of an insulation manufacturer.

Update: After pulling new Mueller with elastomeric insulation over a year ago copper still looks clean and system is running great. Luckily System used PVE oil so after pulling it down many times over 5 days with quite a few pump oil changes I was able to finally get it to hold below 500 Micron over night. Imagine how many consumers will blame the ductless technology when it’s really just poor quality control on behalf of an insulation manufacturer.

Appears to primarily be a co-extruded issue where the insulation is tight against the copper and all white. There are other white covered line sets that use a grey insulation with some air gap and a white cover. THere has been changes to the co-extruded linesets as well with a polymer barrier (plastic coating) that seems to be in place to mitigate the direct contact with the copper.

The grey insulation surrounded by the white seems fine. I have tested them for the PH and its neutral. Bottom line is if you suspect a problem line set, test several sections with PH sensitive paper. The stuff is cheap and will give you a thumbs up or down!

Appears to primarily be a co-extruded issue where the insulation is tight against the copper and all white. There are other white covered line sets that use a grey insulation with some air gap and a white cover. THere has been changes to the co-extruded linesets as well with a polymer barrier (plastic coating) that seems to be in place to mitigate the direct contact with the copper.

The grey insulation surrounded by the white seems fine. I have tested them for the PH and its neutral. Bottom line is if you suspect a problem line set, test several sections with PH sensitive paper. The stuff is cheap and will give you a thumbs up or down!

I too have a line set problem, system installed 11/2021 used only a few weeks last summer 2022 and heat pump for six weeks. in winter of 2022. 3hours of troubleshooting 400 dollars later still not fixed need to come back later with new line set. Tech automatically changed all 12 fitting before pulling a vacuum check. then checked and found bubbling up from insulation. i would think you do a leak check before just changing part. parts are covered but not labor. I have a 3 zone unit, what to say other line sets won`t go bad also. For all i know stuff was probally orderd from amazon to max profit

I too have a line set problem, system installed 11/2021 used only a few weeks last summer 2022 and heat pump for six weeks. in winter of 2022. 3hours of troubleshooting 400 dollars later still not fixed need to come back later with new line set. Tech automatically changed all 12 fitting before pulling a vacuum check. then checked and found bubbling up from insulation. i would think you do a leak check before just changing part. parts are covered but not labor. I have a 3 zone unit, what to say other line sets won`t go bad also. For all i know stuff was probally orderd from amazon to max profit

We’ve seen this issue on multiple systems now and it makes me very nervous. Not looking forward to explaining this to the homeowners…

I question the effectiveness of caulking the ends of the line set- the reason I say this is because I’ve seen how UV breaks down any of the exposed white insulation and it is porous within a year or so and will allow moisture in regardless of how well you caulked both ends…

We’ve seen this issue on multiple systems now and it makes me very nervous. Not looking forward to explaining this to the homeowners…

I question the effectiveness of caulking the ends of the line set- the reason I say this is because I’ve seen how UV breaks down any of the exposed white insulation and it is porous within a year or so and will allow moisture in regardless of how well you caulked both ends…

…. I’m a homeowner and had this explained to me today. Corrosion on the line set. I had the unit installed in 2018 and it was completely out of refrigerant. The tech determined that there were mini-leaks in the copper and it’s going to have to be replaced. Looks like I’m just one of many customers who had this issue. I accept the explanation. At least my guy found the problem and it can be fixed. (hope this makes sense–I’m a consumer, not an HVAC worker)

…. I’m a homeowner and had this explained to me today. Corrosion on the line set. I had the unit installed in 2018 and it was completely out of refrigerant. The tech determined that there were mini-leaks in the copper and it’s going to have to be replaced. Looks like I’m just one of many customers who had this issue. I accept the explanation. At least my guy found the problem and it can be fixed. (hope this makes sense–I’m a consumer, not an HVAC worker)

Hopefully your unit didn't sit flat to long with POE oil as the damage maybe done. Mitsubishi units use PVE oil which is more forgiving

Hopefully your unit didn't sit flat to long with POE oil as the damage maybe done. Mitsubishi units use PVE oil which is more forgiving

[url=https://seattlehourlylimo.com/]Seattle hourly Limo[/url] and Limo Service Seattle offer flexible, reliable luxury transportation. Book hourly rates for stylish rides to any event or destination in comfort!

[url=https://seattlehourlylimo.com/]Seattle hourly Limo[/url] and Limo Service Seattle offer flexible, reliable luxury transportation. Book hourly rates for stylish rides to any event or destination in comfort!

To leave a comment, you need to log in.

Log In