Get Tech Tips

Subscribe to free tech tips.

Plenum Takeoffs Best Practices

In my second year in HVAC, I went out with a senior technician to install a supply duct for a bathroom in a house. While he ran the duct, I cut a hole in the plenum and attached the collar. He crawled back across the attic and very nicely told me that people don’t typically cut holes into the end of plenums. I had never thought about where on a plenum a duct needed to go.

Where are the best places to attach your takeoffs from a plenum? What are the pros and cons of the various locations we can tap our ducts onto? The more we understand about the principles behind duct design and airflow, the better decisions we can make in the design and installation phase.

Bernoulli

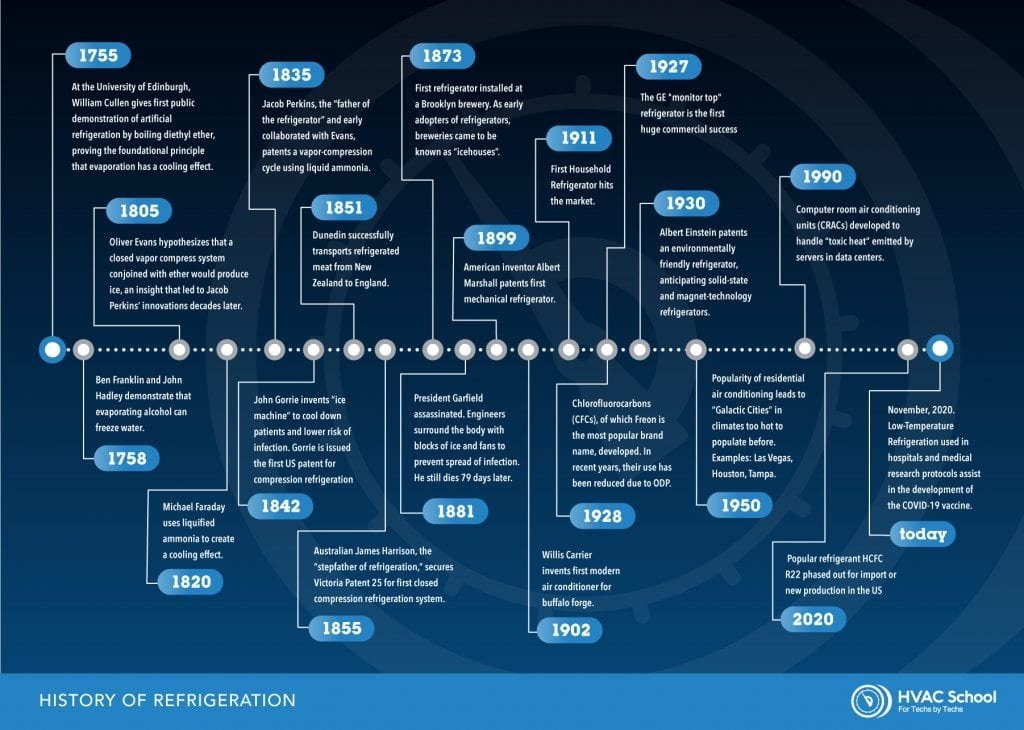

Let’s start at the beginning with a dude named Bernoulli, who was born in the year 1700. This handsome fella was a scientist and mathematician who figured out some things about pressure and flow that we use all the time. Thanks, Berni!

Bryan wrote an article a while back about Bernoulli and his principle. What does it say? It describes the relationship between velocity pressure and static pressure. Basically, if one goes up, the other goes down. So, if velocity pressure increases, static pressure goes down. If static pressure increases, velocity pressure decreases. It all ties back to the law of conservation of energy! The conservation of energy law states that energy can be neither created nor destroyed, but it can convert from one form to another.

How do we make that conversion happen? A lot of it has to do with increasing and decreasing the size and shape of the vessel that the fluid moves within, as you can see in the picture below. Then you need something to move the fluid, like a pump or gravity.

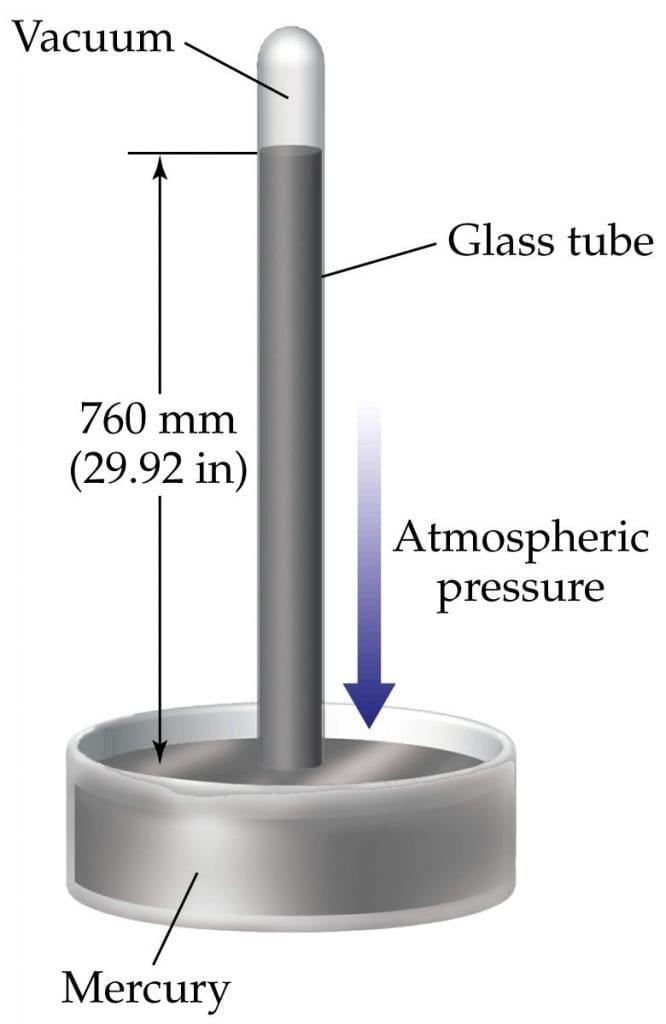

What exactly is static pressure? Well, air is a fluid and static pressure is a term that comes from the study of fluid dynamics. Static pressure is the force exerted against the surfaces of the container the fluid is contained in.

The most commonly used example is a balloon filled with air. If you were to measure the pressure of a balloon filled with air and compare it to atmospheric pressure, you would find that the balloon has a higher pressure. But the air in the balloon isn’t moving. Now, let’s say you’ve been holding the balloon shut with your fingers and then let it go. What will happen?

The static pressure will begin to drop, and the velocity pressure will increase until the balloon reaches equilibrium with the surrounding air. This is exactly what Bernoulli was talking about! Static pressure is sort of a way of measuring energy. All that pressure was trapped inside the balloon until it had somewhere to go. Static pressure allows us to measure that outward exerting force.

So, static pressure is non-moving pressure in a duct system. In fact, inches of water column can be converted to PSI.

Static Regain

In ductwork, we see this principle in dramatic action on the inlet and outlet of the blower motor. Coming right off of the discharge side of the blower motor, we have a large amount of velocity pressure and not much static pressure. It’s pretty much the opposite of the balloon example.

And just like the balloon example, total pressure must remain constant. So, as the high-velocity air leaves its small container (the discharge of the blower) and expands into the larger duct system, the velocity pressure drops, and static pressure begins to increase until the two reach equilibrium.

If you don’t take anything else away from this article, remember this: don’t put a duct in the area of high velocity pressure and low static pressure right by the blower motor. In essence, the air will “zoom” right by this duct as its high velocity and low static pressure carry it mostly forward and not much outward. Remember, the static pressure at the discharge of the blower motor is very low. There isn’t much pressure against the walls of the duct system where the collar is tapped on.

You want to attach your ducts according to the two-foot rule, which is a rule of thumb designed to help us avoid those areas of low static pressure.

Avoid the End Cap?

Interestingly, there is not much specific guidance in ACCA Manual D on this matter. The only explicit information of note is this: “The closing plate at the end of a trunk duct causes a turbulent zone in the trunk airway just upstream from the plate. A branch takeoff fitting shall not be installed in this zone. Figure 5-2 shows that the centerline of a branch takeoff shall be at least 18 inches upstream from a trunk end plate or trunk reducing fitting.” (Manual D, page 30)

The picture above is from a great NCI article by John Puryear about the same topic; it helps us understand what Manual D is really saying.

Understand Spacing and Offsetting

John goes on to discuss offsetting takeoffs more generally. He says, “When asked, ‘which is better, to put take-offs directly across from each other or to stagger them,’ most students say to stagger them. This is correct if the stagger is 18 to 24′ on center from each other. Look at the diagram. If you place take-offs too close together, less than 24′ on center, or too close to an air change (elbow or transition), the air doesn’t have time to re-pressurize and create the appropriate turbulent flow.”

Commenting on this topic, Ed Janowiak from ACCA said,

There’s been a lot written over the years when it comes to ducts directly across from each other, ducts downstream from a transition, etc. The one thing that is typically lacking when this testing is done is dampers.

Manual D essentially says to put the takeoffs wherever you want and adjust the dampers. I have found this to work very well. Yes, it can be very time-consuming when you have short distances between the takeoffs, takeoffs from a plenum, or a takeoff anywhere where it’s getting more air than another takeoff to get the desired airflow, but you can do it. One of the things you might have to put up with is noise, but not insufficient airflow.

Ed Janowiak, Manager of HVAC Design Education at Air Conditioning Contractors of America (ACCA)

Putting a duct off of the end cap is not the end of the world as long as you have a damper on it, as Ed mentioned. Dampers cover a multitude of sins. As long as your damper doesn’t create a low-pressure zone and block air from the next duct, you don’t need to worry about spacing, really. It might take some more time to balance the system out, but it’s a much more realistic and less time-consuming approach.

Conclusion

In summary, here are the best practices:

- No takeoffs within 2 feet of the blower motor

- Put dampers on every single run

- If you’re going to use the end cap, put a damper on it

- Use dampers

- Don’t forget the dampers!

—Matt Bruner

Comments

Just watched the podcast on properly pulling a deep vacuum and I must say that it was the most informative video that I have ever watched. I learned so much from that one video! Truly a gem!

Just watched the podcast on properly pulling a deep vacuum and I must say that it was the most informative video that I have ever watched. I learned so much from that one video! Truly a gem!

Pharmacie en ligne livraison Europe pharmacie en ligne france fiable or pharmacie en ligne france livraison belgique

https://www.google.al/url?q=https://pharmafst.com pharmacie en ligne avec ordonnance

[url=https://maps.google.ro/url?sa=t&url=http://pharmafst.com]pharmacie en ligne pas cher[/url] п»їpharmacie en ligne france and [url=https://www.support-groups.org/memberlist.php?mode=viewprofile&u=359691]pharmacies en ligne certifiГ©es[/url] pharmacie en ligne sans ordonnance

Pharmacie en ligne livraison Europe pharmacie en ligne france fiable or pharmacie en ligne france livraison belgique

https://www.google.al/url?q=https://pharmafst.com pharmacie en ligne avec ordonnance

[url=https://maps.google.ro/url?sa=t&url=http://pharmafst.com]pharmacie en ligne pas cher[/url] п»їpharmacie en ligne france and [url=https://www.support-groups.org/memberlist.php?mode=viewprofile&u=359691]pharmacies en ligne certifiГ©es[/url] pharmacie en ligne sans ordonnance

Tadalafil 20 mg prix sans ordonnance Tadalafil 20 mg prix en pharmacie or Tadalafil sans ordonnance en ligne

https://images.google.mn/url?q=https://tadalmed.com Cialis sans ordonnance 24h

[url=http://redmondlabs.com/eslr/art/?url=http://tadalmed.com/]cialis prix[/url] Tadalafil achat en ligne and [url=https://www.oppo.xyz/home.php?mod=space&uid=18861]Cialis en ligne[/url] Tadalafil sans ordonnance en ligne

Tadalafil 20 mg prix sans ordonnance Tadalafil 20 mg prix en pharmacie or Tadalafil sans ordonnance en ligne

https://images.google.mn/url?q=https://tadalmed.com Cialis sans ordonnance 24h

[url=http://redmondlabs.com/eslr/art/?url=http://tadalmed.com/]cialis prix[/url] Tadalafil achat en ligne and [url=https://www.oppo.xyz/home.php?mod=space&uid=18861]Cialis en ligne[/url] Tadalafil sans ordonnance en ligne

Cialis sans ordonnance 24h: Tadalafil achat en ligne – Cialis en ligne tadalmed.shop

Cialis sans ordonnance 24h: Tadalafil achat en ligne – Cialis en ligne tadalmed.shop

pharmacie en ligne [url=http://pharmafst.com/#]pharmacie en ligne[/url] pharmacie en ligne sans ordonnance pharmafst.shop

pharmacie en ligne [url=http://pharmafst.com/#]pharmacie en ligne[/url] pharmacie en ligne sans ordonnance pharmafst.shop

olympe casino en ligne: casino olympe – olympe casino cresus

olympe casino en ligne: casino olympe – olympe casino cresus

Regarding Branch Take-off fittings and TEL, this statement is exactly opposite that stated in Understanding Manual D, Jack Rise. The more take-off further down stream of the the installed take-off in question the longer the the TEL. The take-off closest to the end of the plenum or trunk receives air first as the fan pressurizes the duct when the air flow hits the end of the plenum or trunk. The last take-off to receive air is the one closest to the fan.

Regarding Branch Take-off fittings and TEL, this statement is exactly opposite that stated in Understanding Manual D, Jack Rise. The more take-off further down stream of the the installed take-off in question the longer the the TEL. The take-off closest to the end of the plenum or trunk receives air first as the fan pressurizes the duct when the air flow hits the end of the plenum or trunk. The last take-off to receive air is the one closest to the fan.

Hi Jason,

can you post those pages? I looked pretty extensively through manual D and could not find much guidance on takeoffs. Although Ed Janiowak from ACCA did inform me that there is guidance for putting takeoffs on the end of a plenum, so I need to update the article. Anyways, any information you can point me to (page numbers, scans of the document) would be great. I do not have a copy of Understanding Manual D!

Ed from ACCA also mentioned he is a fan of simply putting dampers on all the runs and not worrying too much about which duct gets tapped where. More food for thought!

Matt

Hi Jason,

can you post those pages? I looked pretty extensively through manual D and could not find much guidance on takeoffs. Although Ed Janiowak from ACCA did inform me that there is guidance for putting takeoffs on the end of a plenum, so I need to update the article. Anyways, any information you can point me to (page numbers, scans of the document) would be great. I do not have a copy of Understanding Manual D!

Ed from ACCA also mentioned he is a fan of simply putting dampers on all the runs and not worrying too much about which duct gets tapped where. More food for thought!

Matt

Sorry Matt, I don’t see a way to post images or pdf’s. Please reefer to page 54 and 55 in Understanding Manual D by Jack Rise for an understanding of the design principles as described in Manual D. Regarding dampers, that’s pretty much how it’s done as you size the friction rate on the longest TEL of both supply and exhaust runs together. If you can get the required airflow to the worst case scenario, you’ll have no trouble (and need a damper) to deliver the design airflow to the shorter (less restrictive) runs.

Sorry Matt, I don’t see a way to post images or pdf’s. Please reefer to page 54 and 55 in Understanding Manual D by Jack Rise for an understanding of the design principles as described in Manual D. Regarding dampers, that’s pretty much how it’s done as you size the friction rate on the longest TEL of both supply and exhaust runs together. If you can get the required airflow to the worst case scenario, you’ll have no trouble (and need a damper) to deliver the design airflow to the shorter (less restrictive) runs.

Ah, we may not have that feature. Thank you for the information!

Ah, we may not have that feature. Thank you for the information!

pharmacie en ligne france fiable: Pharmacies en ligne certifiees – pharmacies en ligne certifiГ©es pharmafst.com

pharmacie en ligne france fiable: Pharmacies en ligne certifiees – pharmacies en ligne certifiГ©es pharmafst.com

To leave a comment, you need to log in.

Log In