Get Tech Tips

Subscribe to free tech tips.

Don’t Forget the Suction Filter Drier

Courtesy of Emerson

It is important to have refrigerant free from debris and contaminants, and we control these issues on many different fronts.

1. Proper tubing handling prevents copper shavings, dirt, and water from entering while installing.

2. Flowing nitrogen while brazing prevents carbon build-up.

3. Deep vacuum of 500 microns or less removes air, nitrogen, and moisture.

4. Installation of a liquid line filter drier keeps contaminants from hitting the metering device.

But in all this, we can forget the role that suction driers can play in protecting the compressor and the compressor oil.

When do we install suction driers?

In air conditioning, we rarely install suction driers unless we know there is acid contamination, such as in the case of a compressor burnout. Interestingly, Copeland actually recommends suction driers in ALL applications in bulletin AE24-1105 R5.

While I certainly don't think that we need to change our practices and begin installing suction line filter driers on every single installation, it does get you thinking about the role a suction drier can play in protecting a compressor.

Burnout best practices

In a typical burnout application where acid is present, it is a good practice to:

- Remove/flush as much contaminated oil from the system as possible considering the application, including any oil traps, separators, or accumulators.

- Install a high-capacity acid removal suction and liquid drier or removable core(s).

- Some contractors will add acid neutralizers, such as Rectorseal's Acid Away, in certain applications.

- Return after running the system for a while, test for acid, and replace high-capacity filter driers with new ones if required.

- Once the acid is no longer present, return and remove the suction filter/drier and install a standard liquid line drier or core.

These practices above are good, general practices to follow, but you may consider replacing the suction drier with a standard, high capacity, low-pressure drop suction drier with two pressure ports instead of just straight piping it. That will provide you an extra layer of protection for the compressor should any acid or contaminants from the burnout make their way to the compressor.

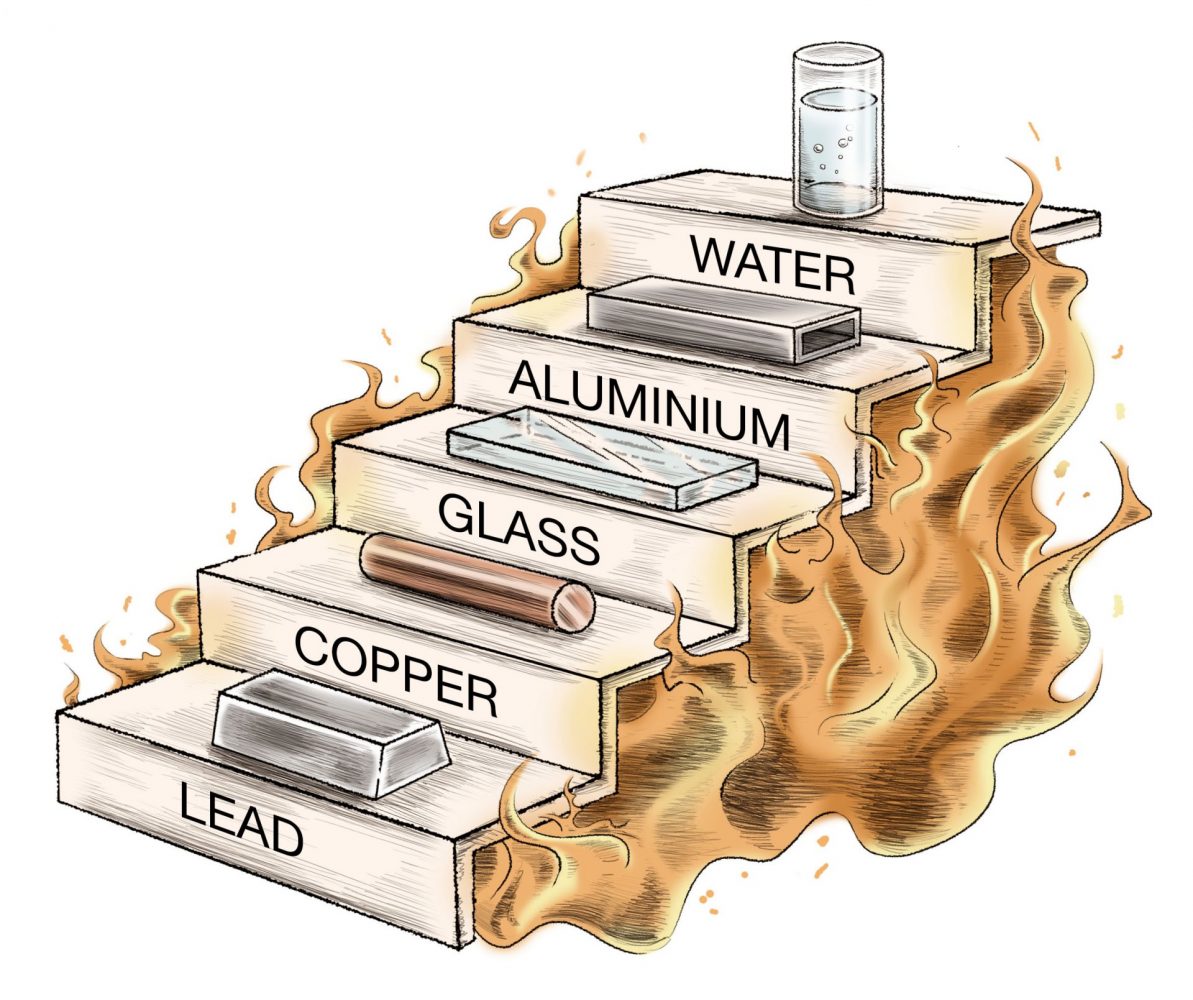

Table Courtesy of Emerson

If you choose to LEAVE a suction drier in a system, there are a few things to consider.

- As with a liquid line filter drier, install a suction filter drier that is large enough for the system's capacity. Read the info on the drier or the manufacturer's data to make sure it is large enough so that you don't start with a restriction.

- Make sure you don't burn the paint on the drier when installing. Because suction driers on air conditioning will often be exposed to the elements, you want to make sure the paint is intact so that the suction driers don't rust.

- Use a suction filter/drier with ports on both sides and measure the pressure drop whenever you service the unit. Make sure the pressure drop does not exceed the levels shown in the chart above.

All in all, having a suction drier in the system is a good thing, so long as it isn't contaminated, rusty, or restricted.

—Bryan

P.S. – Sporlan has a great catalog of filter driers HERE. Sporlan's Senior Application Engineer, Jim Jansen, also gave an informative presentation about filter driers and contamination cleanup at the 4th Annual HVACR Training Symposium. You can learn more about that session or watch it with your virtual ticket HERE.

Comments

We put low pressures switch on the exit side of the dryer, often space requires the use of a low capacity pancake.

We put low pressures switch on the exit side of the dryer, often space requires the use of a low capacity pancake.

Kamagra Oral Jelly pas cher Achetez vos kamagra medicaments or kamagra 100mg prix

http://www.google.li/url?q=http://kamagraprix.com Acheter Kamagra site fiable

[url=http://www.nightdriv3r.de/url?q=https://kamagraprix.com]Kamagra Oral Jelly pas cher[/url] achat kamagra and [url=https://bbs.hy2001.com/home.php?mod=space&uid=70358]Kamagra pharmacie en ligne[/url] achat kamagra

Kamagra Oral Jelly pas cher Achetez vos kamagra medicaments or kamagra 100mg prix

http://www.google.li/url?q=http://kamagraprix.com Acheter Kamagra site fiable

[url=http://www.nightdriv3r.de/url?q=https://kamagraprix.com]Kamagra Oral Jelly pas cher[/url] achat kamagra and [url=https://bbs.hy2001.com/home.php?mod=space&uid=70358]Kamagra pharmacie en ligne[/url] achat kamagra

Pharmacie Internationale en ligne Pharmacie Internationale en ligne or Pharmacie sans ordonnance

https://maps.google.jo/url?q=https://pharmafst.com pharmacie en ligne france livraison internationale

[url=http://fandyweb.websui.com/_m/index.php?a=free_page/goto_mobile&referer=https://pharmafst.com]п»їpharmacie en ligne france[/url] acheter mГ©dicament en ligne sans ordonnance and [url=http://lsdsng.com/user/723642]vente de mГ©dicament en ligne[/url] Pharmacie en ligne livraison Europe

Pharmacie Internationale en ligne Pharmacie Internationale en ligne or Pharmacie sans ordonnance

https://maps.google.jo/url?q=https://pharmafst.com pharmacie en ligne france livraison internationale

[url=http://fandyweb.websui.com/_m/index.php?a=free_page/goto_mobile&referer=https://pharmafst.com]п»їpharmacie en ligne france[/url] acheter mГ©dicament en ligne sans ordonnance and [url=http://lsdsng.com/user/723642]vente de mГ©dicament en ligne[/url] Pharmacie en ligne livraison Europe

Kamagra Commander maintenant kamagra 100mg prix or Acheter Kamagra site fiable

https://www.google.vg/url?q=https://kamagraprix.shop Kamagra pharmacie en ligne

[url=https://www.google.gl/url?q=https://kamagraprix.shop]Kamagra Commander maintenant[/url] achat kamagra and [url=http://umsr.fgpzq.online/home.php?mod=space&uid=10421]Kamagra Oral Jelly pas cher[/url] Acheter Kamagra site fiable

Kamagra Commander maintenant kamagra 100mg prix or Acheter Kamagra site fiable

https://www.google.vg/url?q=https://kamagraprix.shop Kamagra pharmacie en ligne

[url=https://www.google.gl/url?q=https://kamagraprix.shop]Kamagra Commander maintenant[/url] achat kamagra and [url=http://umsr.fgpzq.online/home.php?mod=space&uid=10421]Kamagra Oral Jelly pas cher[/url] Acheter Kamagra site fiable

pharmacie en ligne france pas cher: pharmacie en ligne sans ordonnance – pharmacie en ligne france livraison belgique pharmafst.com

pharmacie en ligne france pas cher: pharmacie en ligne sans ordonnance – pharmacie en ligne france livraison belgique pharmafst.com

https://kamagraprix.com/# kamagra gel

https://kamagraprix.com/# kamagra gel

Tadalafil achat en ligne [url=https://tadalmed.shop/#]Pharmacie en ligne Cialis sans ordonnance[/url] Cialis en ligne tadalmed.com

Tadalafil achat en ligne [url=https://tadalmed.shop/#]Pharmacie en ligne Cialis sans ordonnance[/url] Cialis en ligne tadalmed.com

pharmacie en ligne fiable: pharmacie en ligne sans ordonnance – pharmacie en ligne france pas cher pharmafst.com

pharmacie en ligne fiable: pharmacie en ligne sans ordonnance – pharmacie en ligne france pas cher pharmafst.com

pharmacie en ligne france livraison internationale: Meilleure pharmacie en ligne – pharmacie en ligne france livraison internationale pharmafst.com

pharmacie en ligne france livraison internationale: Meilleure pharmacie en ligne – pharmacie en ligne france livraison internationale pharmafst.com

olympe casino avis: olympe casino – olympe casino cresus

olympe casino avis: olympe casino – olympe casino cresus

To leave a comment, you need to log in.

Log In