Get Tech Tips

Subscribe to free tech tips.

Dielectric Grease: What It Is and How To Use It

Dielectric grease is an often misused and misunderstood product that could easily benefit HVAC/R technicians in various ways. From food service to electrical connections, dielectric grease can help lubricate mechanical components and prevent corrosion on electrical connections. But we need to understand what it is in the first place before we can properly apply it in the field.

Dielectric grease is silicone-based grease with insulating properties. Common uses for dielectric grease include electrical connections, spark plug wires, and mechanical connections. The most common misuse of dielectric grease relates to electrical connections.

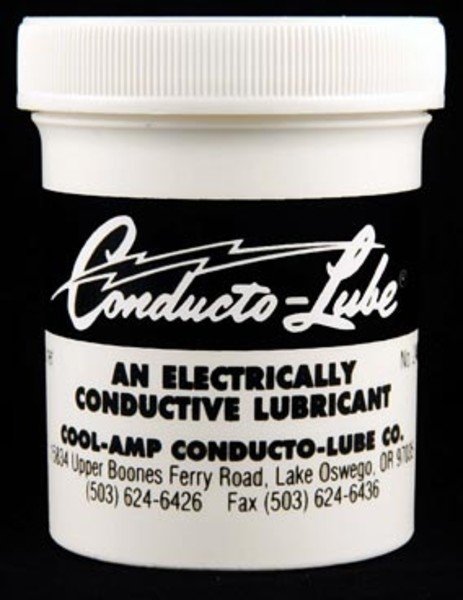

I mentioned that dielectric grease acts as an insulator, yet many technicians mistake silicone grease as conductive. If you're looking for conductive grease, Conducto-Lube Silver or any carbon conductive grease will do. Conductive grease is for conducting electricity from one conductor through the grease to another conductor.

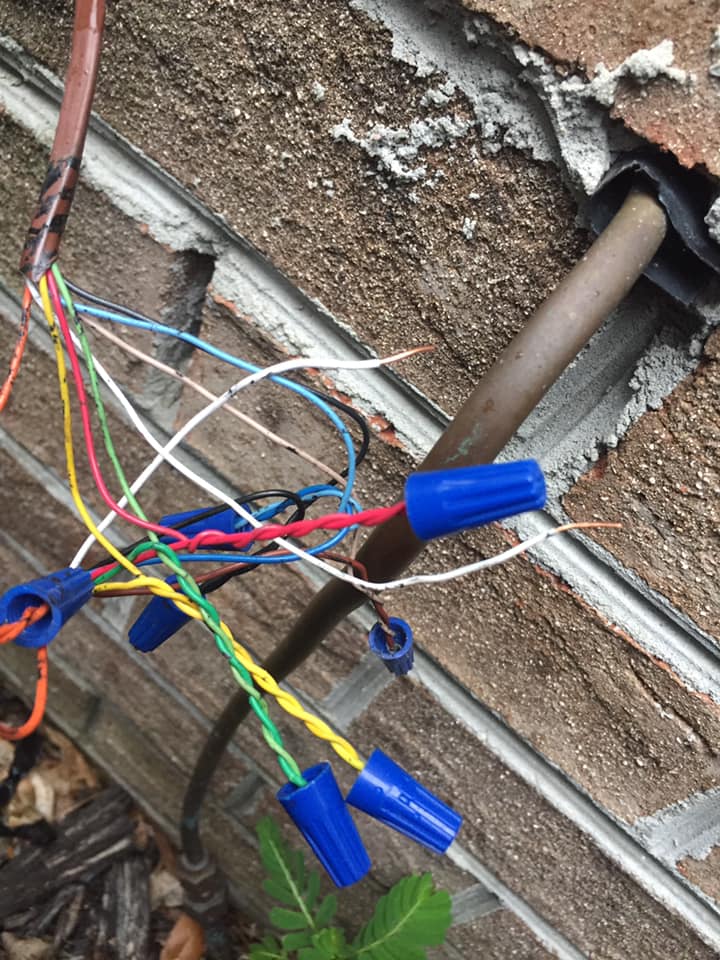

To apply silicone dielectric grease properly to electrical connections, make sure the conductor mating surfaces are bonded before applying the grease. In coastal climates, low voltage wiring is particularly in danger of corrosion, especially right on the waterfront.

To prevent corrosion and protect the connections, make a solid connection with your exposed conductor wire with an appropriately sized wire nut. Then, remove the wire nut and dip the exposed conductor into dielectric grease. Next, put the wire nut back on. If you really want to get crazy, you can then wrap the connection with electrical tape. For contactors and other connections, wire up the components as usual, then apply a dollop of Daisy—I mean, dielectric grease—to the connection points.

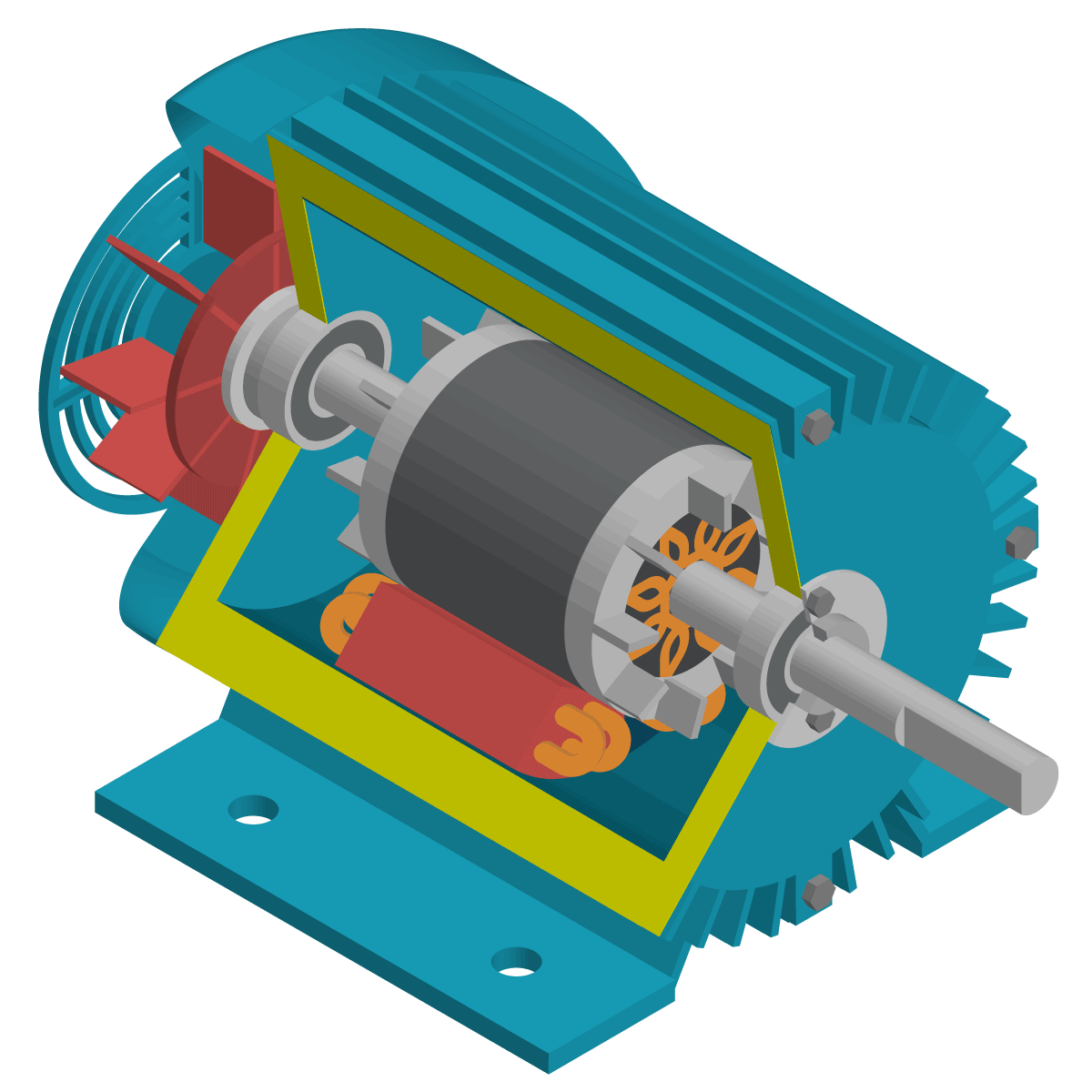

You can use dielectric grease in a variety of mechanical applications as well. The Refrigeration Technologies silicone grease is also food-grade and is suitable for many refrigeration applications.

Remember to always double-check your electrical and mechanical connections for the correct torque before applying the grease. If you’re not careful, things can get messy quickly!

—Kaleb

Comments

Confused – you note that dielectric grease is non-conductive (insulating), then state to dip exposed (presumed copper) wires in it to help the electrical connection.

Isn’t conductive grease the appropriate grease in this application? Or is it assumed that the twisted wire formed by linemans/wirenut is forming an adequate connection, and the insulating silicone grease is then added to just keep outside forces (corrosion, arcing) away?

Confused – you note that dielectric grease is non-conductive (insulating), then state to dip exposed (presumed copper) wires in it to help the electrical connection.

Isn’t conductive grease the appropriate grease in this application? Or is it assumed that the twisted wire formed by linemans/wirenut is forming an adequate connection, and the insulating silicone grease is then added to just keep outside forces (corrosion, arcing) away?

нейросеть для создания рефератов в ворде

нейросеть для создания рефератов в ворде

Нейросети для рефератов https://neyroseti-dlya-referatov.ru/

Нейросети для рефератов https://neyroseti-dlya-referatov.ru/

Site https://fotonons.ru/zanyatiya-figurnym-kataniem-dlya-vzroslyh-sport-kotoryj-menyaet-zhizn/

Site https://fotonons.ru/zanyatiya-figurnym-kataniem-dlya-vzroslyh-sport-kotoryj-menyaet-zhizn/

minotaurus crypto

minotaurus crypto

Chicken Road tips

Chicken Road tips

Greetings!

Kidney care goes beyond stones—our urology clinic manages hydronephrosis, cysts, and tumors. Nephrology referral is coordinated when kidney function declines. Ultrasound for kidneys and CT urogram provide detailed imaging. Preventive urology includes screening and hydration coaching. Protect your kidneys with proactive, comprehensive care.

More details on the website — https://ciopucise.shop/

urology diagnostics, balance exercises urology, evidence summaries urology

prostate health, autism-friendly urology, free urology screening

Good luck and good health!!

Greetings!

Kidney care goes beyond stones—our urology clinic manages hydronephrosis, cysts, and tumors. Nephrology referral is coordinated when kidney function declines. Ultrasound for kidneys and CT urogram provide detailed imaging. Preventive urology includes screening and hydration coaching. Protect your kidneys with proactive, comprehensive care.

More details on the website — https://ciopucise.shop/

urology diagnostics, balance exercises urology, evidence summaries urology

prostate health, autism-friendly urology, free urology screening

Good luck and good health!!

Website https://fishexpo-volga.ru/ .

Website https://fishexpo-volga.ru/ .

Website https://beksai.ru/ .

Website https://beksai.ru/ .

Website https://remonttermexov.ru/ .

Website https://remonttermexov.ru/ .

Website https://photo-res.ru/ .

Website https://photo-res.ru/ .

Website https://photo-res.ru/ .

Website https://photo-res.ru/ .

Website https://beksai.ru/ .

Website https://beksai.ru/ .

Website https://amurplanet.ru/ .

Website https://amurplanet.ru/ .

Website – https://lostfiilmtv.ru/

Website – https://lostfiilmtv.ru/

Website https://amurplanet.ru/ .

Website https://amurplanet.ru/ .

Website https://useit2.ru/.

Website https://useit2.ru/.

Website https://ipodtouch3g.ru/ .

Website https://ipodtouch3g.ru/ .

Website – https://gorod.kr.ua/forum/showthread.php?p=308275#post308275 .

Website – https://gorod.kr.ua/forum/showthread.php?p=308275#post308275 .

Website https://photo-res.ru/ .

Website https://photo-res.ru/ .

Website https://tione.ru/ .

Website https://tione.ru/ .

Website https://remonttermexov.ru/ .

Website https://remonttermexov.ru/ .

Website https://beksai.ru/ .

Website https://beksai.ru/ .

Website https://ipodtouch3g.ru/ .

Website https://ipodtouch3g.ru/ .

Website https://cardsfm.ru/ .

Website https://cardsfm.ru/ .

Website https://remonttermexov.ru/ .

Website https://remonttermexov.ru/ .

Website https://tione.ru/ .

Website https://tione.ru/ .

Website https://fishexpo-volga.ru/ .

Website https://fishexpo-volga.ru/ .

Website https://photo-res.ru/ .

Website https://photo-res.ru/ .

Website https://beksai.ru/ .

Website https://beksai.ru/ .

Website https://remonttermexov.ru/ .

Website https://remonttermexov.ru/ .

Website https://ipodtouch3g.ru/ .

Website https://ipodtouch3g.ru/ .

Website https://church-bench.ru/ .

Website https://church-bench.ru/ .

Website https://ipodtouch3g.ru/ .

Website https://ipodtouch3g.ru/ .

Website https://useit2.ru/.

Website https://useit2.ru/.

Website https://useit2.ru/.

Website https://useit2.ru/.

It is for preventing corrosion as well as insulating from any other conductive materials that may enter the wire nut like rain or bugs. You are correct in thinking the twisted wire is adequate for the connection as you are putting it back into the wire nut after the grease is applied. Its still important to make sure the wire nut is secured because if the wire is pressed onto something grounded it can still arc or blow a fuse.

It is for preventing corrosion as well as insulating from any other conductive materials that may enter the wire nut like rain or bugs. You are correct in thinking the twisted wire is adequate for the connection as you are putting it back into the wire nut after the grease is applied. Its still important to make sure the wire nut is secured because if the wire is pressed onto something grounded it can still arc or blow a fuse.

https://orb11ta.asia is online now!

https://orb11ta.asia is online now!

To leave a comment, you need to log in.

Log In