Get Tech Tips

Subscribe to free tech tips.

Diagnosing ECM & X13 Motors

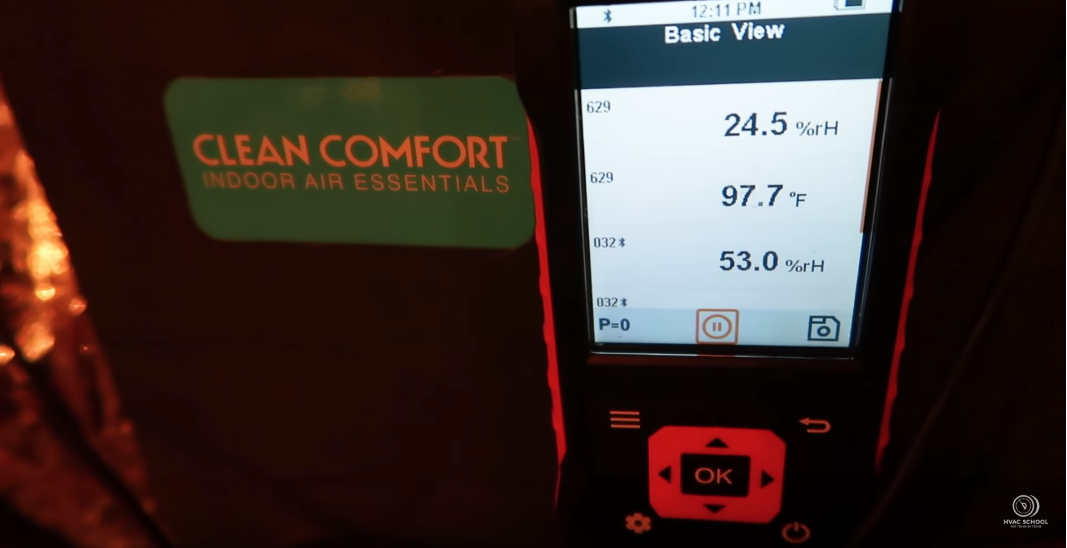

First, let's give proper credit. Most of the best practices and tools for diagnosing ECM and X13 motors come from Regal/Genteq and their site, thedealertoolbox.com, and their app, The Dealer Toolbelt (available on the App Store and Google Play). Your best bet is to follow the practices shown there and use their TECInspect diagnostic tool shown below.

Here is the general process to follow when checking an ECM and X13 motor that isn't running. Most of them are very common practices you would follow with any motor:

- Check for proper line voltage and 24v calls to the proper terminals in the equipment.

- Check for proper control signal entering the motor from the 24v field wiring or boards. The fan speed selections and programming will vary by manufacturer, but the intent is to see if there is a proper control input signal. That can be a bit challenging and is the primary purpose of the TECInspect tool.

- Disconnect power and remove the blower housing.

- Check for abnormal sounds and side-to-side bearing play. Because these motors have permanent magnets on the rotor, they won't spin freely like a normal motor, and you will get an “indexing” feel on the shaft as you turn it.

- Look for signs of overheating, burned spots, etc.

- Remove the module from the motor and disconnect the plug that connects the motor to the module.

- Measure winding to winding on the plug feeding the motor (called phase to phase below). Resistances should be less than 20 ohms and nearly the same between all phases/windings.

- Measure from each winding to ground on the casing, and you should see no less than 100k ohms to ground.

- If the motor checks out OK and the module is receiving inputs, but the motor still isn't running, then it is the module that needs to be replaced.

The diagnosis of ECM and X13 motors is actually pretty easy if you do a bit of reading and take a practical “process of elimination” approach.

—Bryan

P.S. — Chris Mohalley also covered ECM diagnostics in THIS podcast episode. He mentions the same diagnostic tools we covered here and a few more, so it's definitely worth a listen.

Comments

To leave a comment, you need to log in.

Log In