Get Tech Tips

Subscribe to free tech tips.

Cycle Rate Settings – A Quick Review

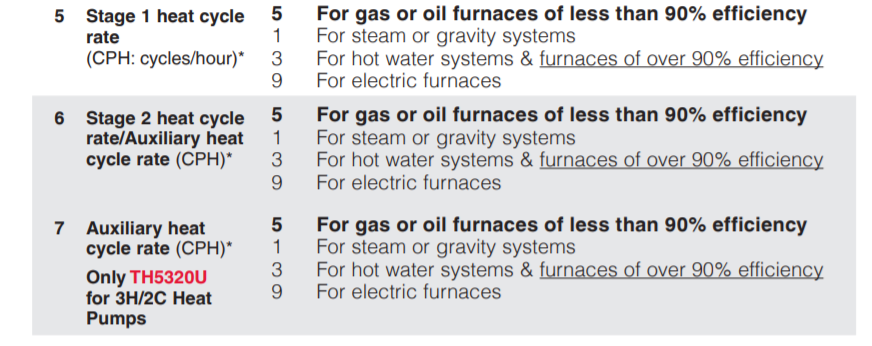

Most controls and thermostats will have some sort of cycle rate per hour setting that kicks in to prevent over-cycling once the setpoint is reached.

These cycle settings don't kick in until the system starts achieving setpoint, so don't worry if it will shut off if it's set to 70° in heat mode and it's 60° in the house. Once it gets to the setpoint, the cycle per hour programming will prevent the system from running MORE cycles per hour than the setting.

When the cycle rate per hour is lower, the run times will be longer, and the off times will be longer.

When the cycle rate is higher, the on times and off times will be shorter.

As a general rule, a lower cycle rate is better for efficiency, and a higher cycle rate is better for comfort. Most equipment is inefficient for a portion of its startup time, so more starting and stopping impacts efficiency due to this “ramp up” time.

Older homes that were poorly sealed and insulated often required more cycles because they would get cold fast when the equipment went off. Nowadays, it is great if we can use three cycles per hour with furnaces and one cycle per hour with heat pump systems to maximize efficiency.

If you get comfort complaints due to wider temperature swings between cycles, you would need to increase the number of cycles, but this is unlikely to be an issue with modern construction.

Also, keep in mind that colder climates may require higher cycle rates due to more extreme differentials between indoor and outdoor temperatures.

You will notice that the thermostat manufacturers show that electric systems can have higher cycle rates. That is because there are no ramp-up losses in electric systems, so there is no real downside to shorter cycles.

—Bryan

Comments

I am with a school in Indianapolis Indiana. We have a 100 ton Chiller with 4 compressors. Two of the compressors failed and had to be replaced.

The cause was identified as too many compressor starts per hour. What should be the Compressor Starts per hour?

Thanks, John

I am with a school in Indianapolis Indiana. We have a 100 ton Chiller with 4 compressors. Two of the compressors failed and had to be replaced.

The cause was identified as too many compressor starts per hour. What should be the Compressor Starts per hour?

Thanks, John

Thanks for sharing your thoughts on %meta_keyword%. Regards

Thanks for sharing your thoughts on %meta_keyword%. Regards

To leave a comment, you need to log in.

Log In