Get Tech Tips

Subscribe to free tech tips.

Condensate Drain Codes & Best Practices

It should be stated and restated that codes and code enforcement vary from location to location within the US. The IMC (International Mechanical Code) is one of the most widely utilized and referenced. The 2015 version of the IMC section 307 is what I will be referring to in this article.

Condensate Disposal

The code as it relates to condensate disposal in the IMC is pretty vague. It says that it must be disposed of in an “approved location” and that it shouldn't be dumped on walkways, streets, or alleys as to “cause a nuisance.”

That leaves us a lot of wiggle room for interpretation and a lot of authority to the AHJ (authority having jurisdiction) and design professionals to establish what is and what isn't an “approved location.” Here are a few good guidelines:

- Don't dump condensate in places that could cause people to slip.

- Don't dump condensate around foundations, basements, or other areas that could cause ponding, erosion, or leakage.

- Don't dump condensate on a roof.

- When discharging into a shared drain or sewer system, ensure that it isn't piped so that waste fumes can enter the system or occupied space.

Drain Sizing

IMC 307.2.2 tells us that an A/C condensate drain inside diameter should not be smaller than 3/4″ and should not be smaller than the drain pan outlet diameter. According to the IMC, 3/4″ is sufficient for up to 20 tons unless the drain outlet size is larger than 3/4″.

Drain Pitch

The IMC dictates a 1% minimum pitch of the drain, equal to 1/8″ fall for every 12″ (foot) of horizontal run. In practice, it is safer to use 1/4″ of fall per foot to ensure proper drainage and provide some wiggle room for error.

Support

Drains can be made out of many materials, but PVC is by far the most common. When a drain line is PVC, the IMC dictates that it should be supported every 4′ horizontally (while maintaining proper pitch) and every 10′ vertically.

Cleanout

IMC 307.2.5 states that the condensate assembly must be installed so that the drain line can be “cleared of blockages and maintained” without cutting the drain.

Traps & Vents

The IMC states that condensate drains should be trapped according to manufacturers' specs. HOWEVER, new wording was added in IMC 307.2.4.1 that states that ductless systems must either have a check valve or a trap in the condensate line. While most manufacturers don't specify this on gravity ductless drains, it is something to look out for.

Venting after the trap (shown in both examples above) is an excellent idea in most applications because it helps prevent airlocks that can occur due to double traps and shared drains. It also prevents siphoning. This vent is AFTER the trap and must remain open to be effective. The vent opening should always rise above the trip level of the condensate overflow switch when it is in the primary drain line or pan or above the secondary/aux overflow port on the primary drain pan. That helps ensure that the water properly trips the switch instead of overflowing out of the vent if a backup occurs. While venting is a common best practice, it isn't required by the IMC.

Drain Insulation

The IMC doesn't directly state that the drain line must be insulated. Many will point to where the ICC energy efficiency code states:

N1103.3

Mechanical system piping insulation. Mechanical system piping capable of carrying fluids above 105°F (40°C), or below 55°F (13°C) shall be insulated to a minimum of R-2.

But that excerpt really isn't talking about condensate drains when read in context.

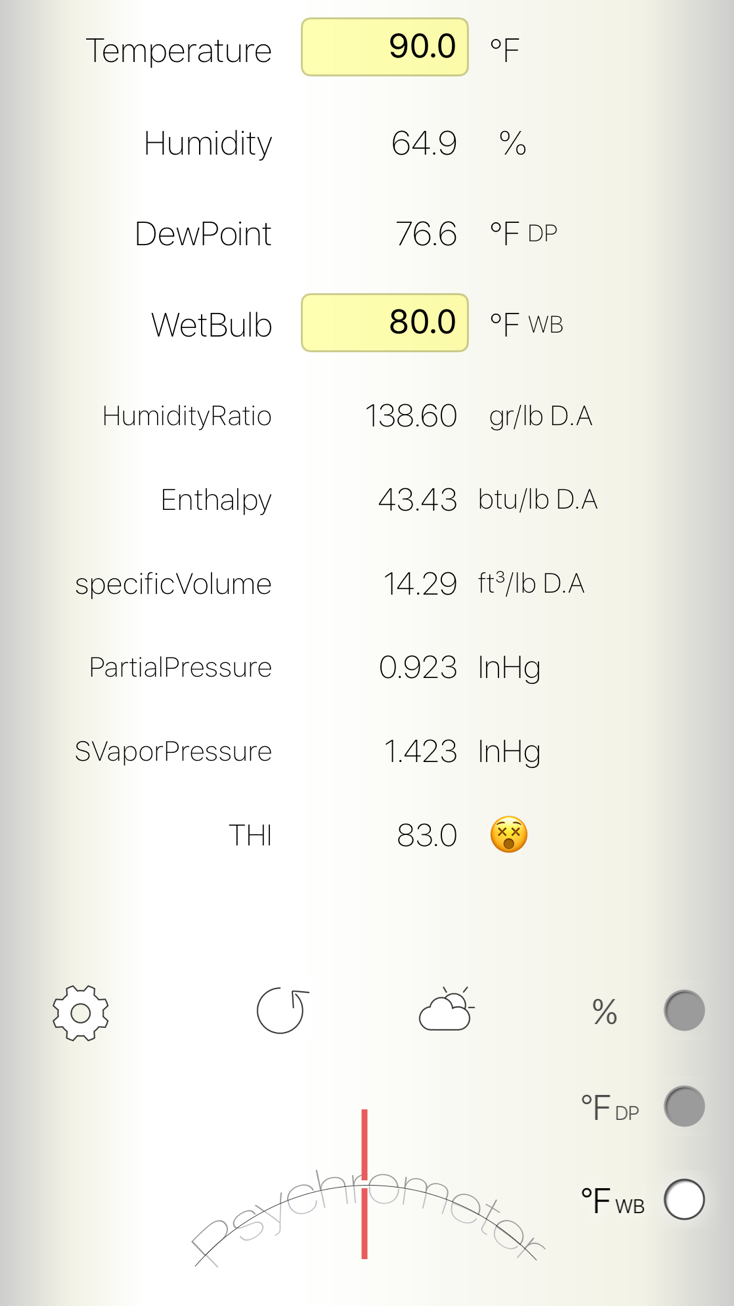

Some municipalities do require that horizontal portions of the drain inside the structure be insulated to prevent condensation, and this standard makes sense to me. In Florida, we always insulate horizontal portions of the drain because we would have consistent growth and water damage issues due to the high dew points if we didn't.

Condensate Switches

IMC 307.2.3 states that all HVAC equipment that produces condensate must have either a secondary drain line or a condensate overflow switch, a secondary drain pan with a secondary drain line, a condensate switch, or some combination of these installations should be used to prevent overflow if the primary drain line blocks.

This code includes rooftop units, ductless units, and downflow units, but the code does allow for the overflow prevention switch to be placed in the primary drain pan in these cases but NOT the primary drain line, according to 307.2.3.1

—Bryan

P.S. – If you're interested in reading a tech tip about drain cleaning best practices, check out this article.

Comments

Good tips and knowledge.

Plz share the about TFA system what is a actually suction pressure and how is it work

Good tips and knowledge.

Plz share the about TFA system what is a actually suction pressure and how is it work

The articles you write help me a lot and I like the topic http://www.goodartdesign.com

The articles you write help me a lot and I like the topic http://www.goodartdesign.com

Treated Fresh Air Units (TFA) are also known as Fresh Air Handling Units (FAHU). Unlike Air Handling Units that are used to recirculate the air in an enclosed space, TFAs cater to large, fresh airflow and recovery needs by treating outdoor air using filters and condition it some degree using a cooling

Treated Fresh Air Units (TFA) are also known as Fresh Air Handling Units (FAHU). Unlike Air Handling Units that are used to recirculate the air in an enclosed space, TFAs cater to large, fresh airflow and recovery needs by treating outdoor air using filters and condition it some degree using a cooling

Sir my one question is it me handel 90 tr dx centerl plant and screw compressor but customer requirements is no air re sarulation .because of progress site toxic type smell his requirements is a 100’/.present fresh air in throw cooling coil and in the process site also exuast air out.so Plz give me best system design. Thank u.

Sir my one question is it me handel 90 tr dx centerl plant and screw compressor but customer requirements is no air re sarulation .because of progress site toxic type smell his requirements is a 100’/.present fresh air in throw cooling coil and in the process site also exuast air out.so Plz give me best system design. Thank u.

Recently learned for 5 ton draw-through systems, the 3/4″ PVC exiting the coil needs several inches of vertical drop to sufficiently create enough water volume & weight to stop back pressure which clearly created spillage/leakage from the drain pan. The picture in the article for a 5 ton system would NOTt be nearly enough to overcome the negative air pressure caused by draw-through air pressure and thus result in coil pan pan spillage.

Recently learned for 5 ton draw-through systems, the 3/4″ PVC exiting the coil needs several inches of vertical drop to sufficiently create enough water volume & weight to stop back pressure which clearly created spillage/leakage from the drain pan. The picture in the article for a 5 ton system would NOTt be nearly enough to overcome the negative air pressure caused by draw-through air pressure and thus result in coil pan pan spillage.

i recently found this out on a 5ton Goodman package heatpump.

i recently found this out on a 5ton Goodman package heatpump.

I’ve got 20 units tied into a 2 inch pipe and recently it started getting backed up.. Does this sound right? What are the specs of pipe needed to drain 20 units that are all over 3 tons each? thanks

I’ve got 20 units tied into a 2 inch pipe and recently it started getting backed up.. Does this sound right? What are the specs of pipe needed to drain 20 units that are all over 3 tons each? thanks

Bobby,

In order for a system that has 20 drain lines draining into a single 2-inch pvc pipe you must have all 20 traps designed properly and all must contain a water seal. I doubt that all traps are filled with water all year. You need to use a “dry-trap” such as the Des Champs HVAC Air-Trap in order for this arrangement to work properly. Can be found at http://www.deschampstechnologies.com

Bobby,

In order for a system that has 20 drain lines draining into a single 2-inch pvc pipe you must have all 20 traps designed properly and all must contain a water seal. I doubt that all traps are filled with water all year. You need to use a “dry-trap” such as the Des Champs HVAC Air-Trap in order for this arrangement to work properly. Can be found at http://www.deschampstechnologies.com

Is it a requirement to install a cleanout for existing systems that need drain cleared but do not have one?

Is it a requirement to install a cleanout for existing systems that need drain cleared but do not have one?

As far as I know, the EZTrap does not have a vent. What’s pictured is a clean out with the cap missing. Is there an error in this article or am I misunderstanding something?

As far as I know, the EZTrap does not have a vent. What’s pictured is a clean out with the cap missing. Is there an error in this article or am I misunderstanding something?

The black stub sticking up is an open vent.

The black stub sticking up is an open vent.

olympe: olympe casino avis – casino olympe

olympe: olympe casino avis – casino olympe

To leave a comment, you need to log in.

Log In