Get Tech Tips

Subscribe to free tech tips.

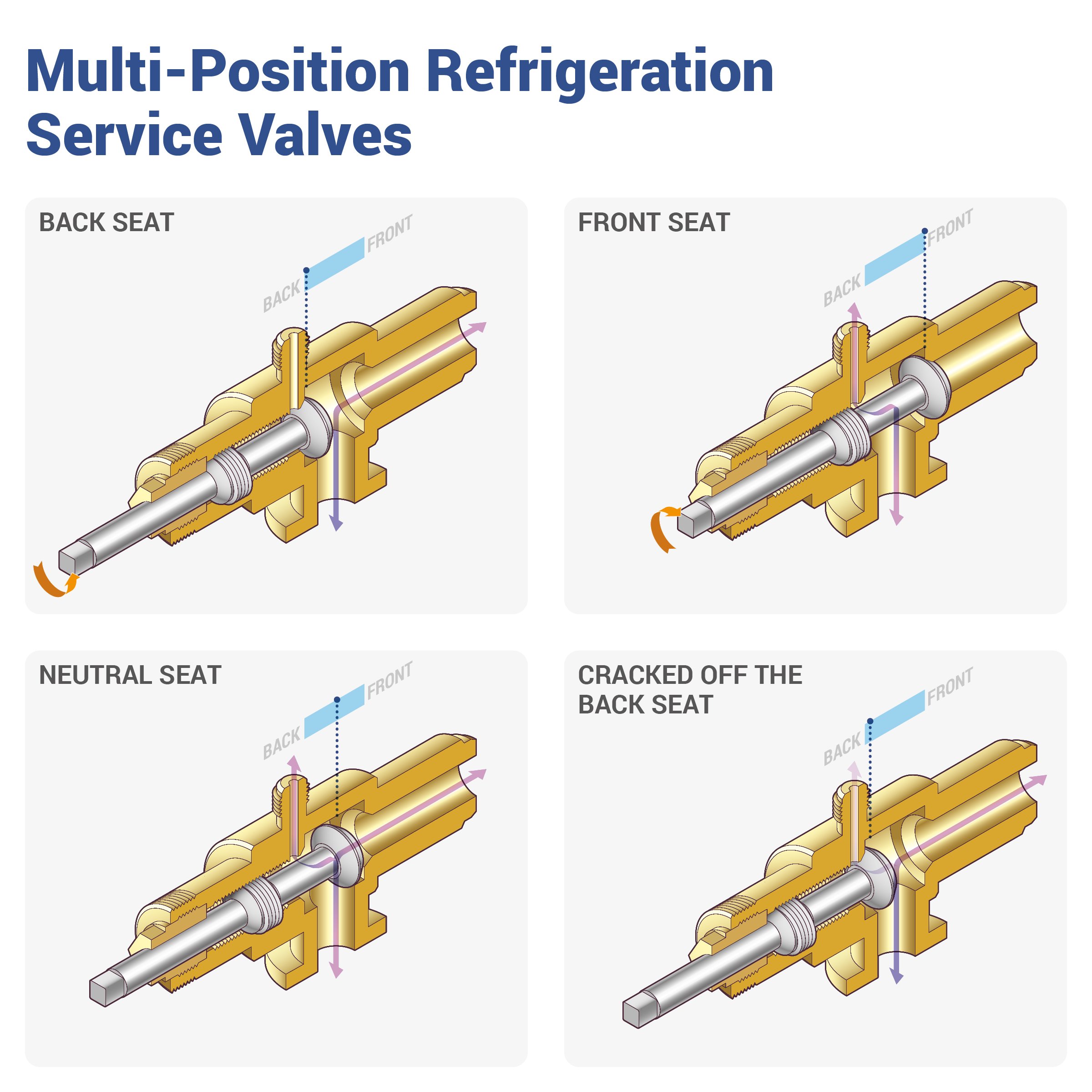

Multi-Position Service Valves

This tech tip video comes from my friend Andrew Greaves of AK HVAC and HVAC Comedy on Youtube and the HVAC Vehicle Layouts group on Facebook. Many residential techs get confused when they see these multi-position valves in larger equipment, and Andrew does a great job of demonstrating the basics in this video.

In the video, Andrew describes the following positions:

Back-Seated (all the way out, fully counter-clockwise)

This position provides full operational flow through the valve body but is closed to the access port. These valves have no Schrader port, so there will be no pressure on the port when the valve stem is back-seated.

Front-Seated (all the way in, fully clockwise)

Front-seated closes the valve and shuts off flow through the system at that point while remaining open to the port. Depending on the valve design, the port may be open to the inside or the outside (inlet or outlet) of the valve; this is important to be aware of when closing. Some compressors have suction and discharge valves, and you must not front-seat (shut off) the discharge valve while the compressor is operating, or extremely high pressures will build instantaneously.

Mid-Seated (valve in the center position, clockwise around 50%)

Mid-seating will provide flow in all directions in, out, and to the port. This position is ideal for vacuum and recovery with the system off.

Cracked off the Back-Seat (turned clockwise just a little)

This is a form of mid-seating where you just turn the stem clockwise enough to get a reading on your gauges. This position is used for testing and charging.

P.S. – Many techs call these King valves, but a King valve is technically a specific liquid line valve on the receiver.

Comments

To leave a comment, you need to log in.

Log In