Get Tech Tips

Subscribe to free tech tips.

Combustion Air

To maintain combustion (burning), you need three things: fuel, heat, and oxygen. If you have all three in the proper proportion, you can maintain a continuous state of combustion.

Remove one (or reduce one sufficiently), and the triangle of combustion can collapse.

In a common natural gas (NG) furnace, the heat is the igniter, the fuel is natural gas, and the oxygen is provided by combustion air.

Combustion air is literally just the air needed to provide a continuous air supply for proper combustion (burning). When burning fuels like natural gas, our goal is to achieve complete combustion where the end products being vented are CO2 and H2O, not CO. This objective requires the right mix of air and fuel.

For perfect combustion, you need about a 10:1 ratio of air to fuel, with safe levels of extra air or “excess air” putting us more into the 13.5:1 to 15:1 range.

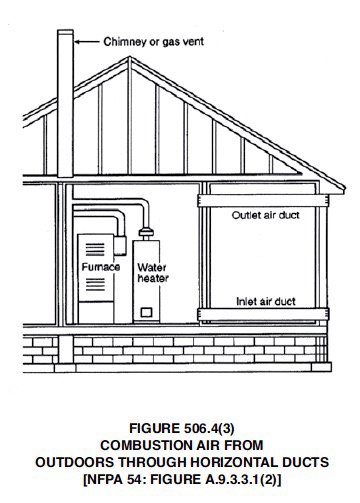

All gas-fired appliances must have both a flue/chimney to exhaust the leftover products of combustion (outlet) and combustion air to provide the oxygen for burning (inlet).

In high-efficiency furnaces, the combustion air is generally piped directly from the outside straight into the combustion chamber. That creates a dedicated source of oxygen and a cleaner install, as no other provisions need to be made for combustion air.

In 80% furnaces, the burners usually have “open” combustion, and they rely on air being drawn into louvers on the furnace cabinet. In this design, the space in which the furnace resides must have open communication to the outdoors or another “uncontained” space.

International Fuel Gas Code (IFGC) Requirements

The IFGC requires the following combustion air openings for a room containing combustion appliances:

Vertical opening – One-inch free area for each 4,000 BTU/hr input of gas-burning appliances in the room.

Horizontal duct opening – One-inch free area for each 2,000 BTU/hr input of gas-burning appliances in the room.

Mechanical fan – One CFM of air for each 2,400 BTU/hr input of gas-burning appliances in the room.

Indoor air – 50 cubic ft. of volume for each 1,000 BTU/hr of the appliances.

My intent isn't to get into the specifics of code because there are lots of specifics that you need to pursue that are beyond the scope of a tip like this. This is all just to say you must have a dedicated method to get significant air to the furnace to ensure safe and complete combustion.

If you don't, the real possibility exists that the furnace could begin burning improperly. Improper burning creates unsafe conditions for the occupants due to carbon monoxide (CO).

Different parts of the country provide combustion air in different ways, but you MUST have some method of providing unlimited fresh air to a furnace or the room in which the furnace is located. That means that when a furnace is in a tight space, ensure that you have some sort of significant combustion air.

—Bryan

Comments

To leave a comment, you need to log in.

Log In