Get Tech Tips

Subscribe to free tech tips.

Charging Systems with Accumulators

In air conditioning service, we don't always see systems with accumulators. In fact, they are pretty uncommon unless you work on a lot of heat pumps. However, as heat pumps gain popularity, charging systems with accumulators will be a good skill to have in your tool bag.

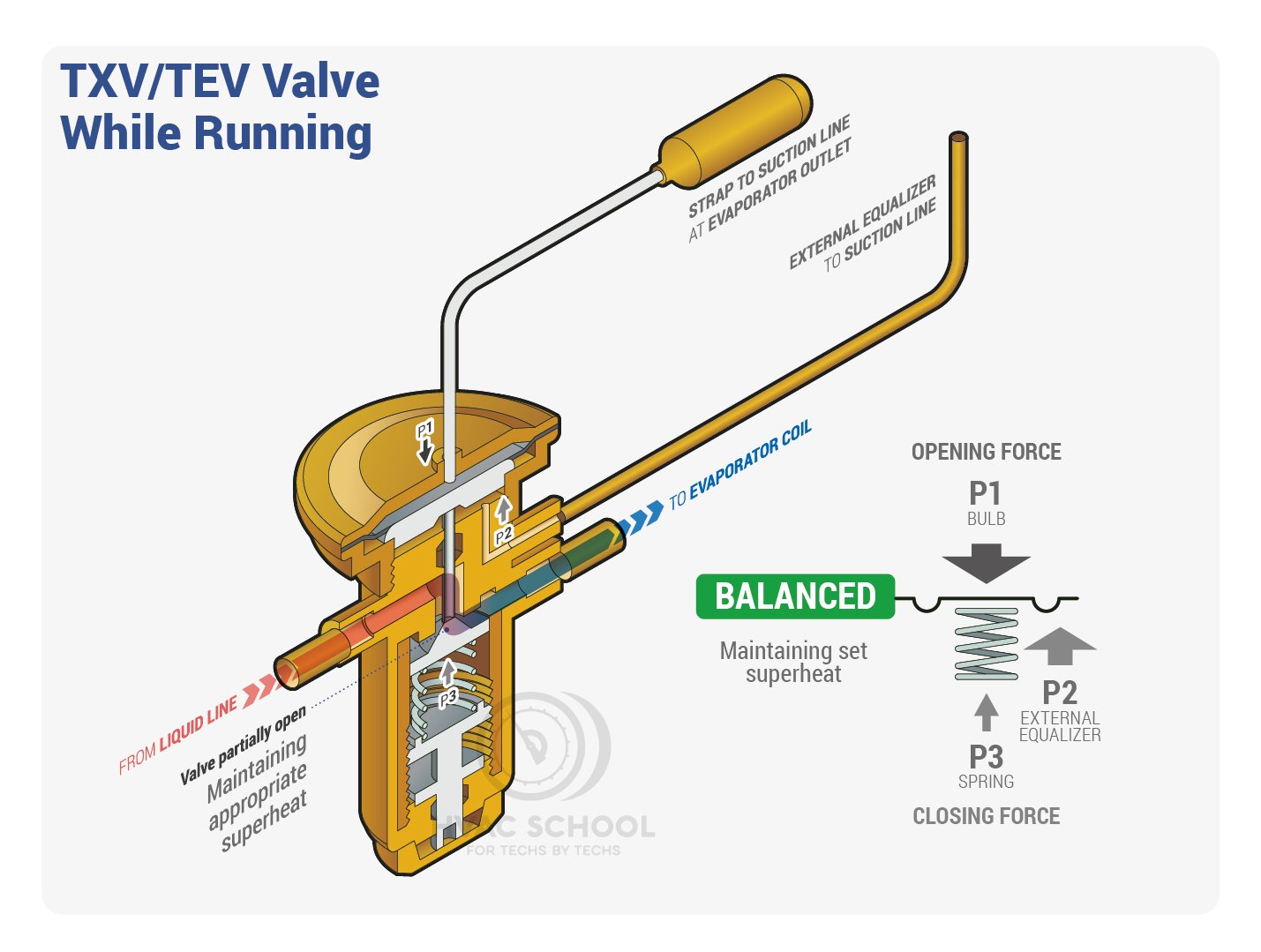

We are Carrier dealers in Florida, so we work on heat pumps with accumulators all the time. The majority of Carrier systems use a fixed orifice piston for the heat mode metering device. These metering devices, pictured below, don't have a sensing bulb that maintains superheat as TXVs do. So, the accumulator is necessary to prevent compressor flooding.

How an accumulator works

As a quick review, the job of the accumulator is to prevent any saturated liquid-vapor mix from entering the compressor directly. The refrigerant travels down the suction (vapor) line and drops into the accumulator. From there, the liquid refrigerant and oil drop to the bottom of the accumulator. The compressor suction then draws from the top of the accumulator to prevent liquid from flooding into the compressor.

There is a small port with a screen at the very bottom of the return u-bend that allows oil and a small amount of liquid refrigerant to return to the compressor. However, it's such a small amount that any liquid will boil off before it makes it to the compressor.

An accumulator is very good at doing its job of protecting the compressor from liquid flooding during certain load conditions, but it can lead to issues with charging if you don't pay attention.

Why is charging a bit more complicated for systems with accumulators?

When adding charge to the suction (vapor) valve on a split heat pump with an accumulator, the liquid refrigerant will enter the suction line, enter the accumulator, fall to the bottom, and collect in the suction accumulator. You can see how liquid collects at the bottom of the accumulator in the image below. As you can see, the system below also has a reversing valve; that's a dead giveaway that the system is a heat pump.

The only way the liquid charged into the accumulator can boil out and enter the compressor is through heat from the ambient outdoor air. That means that as you add liquid refrigerant to a system with an accumulator, it takes more time for your readings to change than in a system with no accumulator.

If you aren't careful, you can easily overcharge an accumulator system due to the delayed response time waiting for the refrigerant to boil out. When we think about best practices to prevent overcharging systems with accumulators, we have to focus on being patient.

Best practices for charging an accumulator system

- When possible, meter in the refrigerant as vapor; this will limit the chilling effect to the accumulator that will result in it holding liquid.

- You can charge carefully into the common suction port if it feeds in after the accumulator. Just be CAREFUL not to flood the compressor.

- Weigh the refrigerant as you add. Allow the charge to stabilize every so often.

- Make sure the system runs a good long while after you are done charging. Giving the system time to stabilize will help you ensure that you won’t overcharge the system.

—Bryan

Comments

To leave a comment, you need to log in.

Log In